Biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and inorganic technology, applied in the field of bio-organic fertilizer and its preparation, can solve the problems of affecting fertilizer efficiency, incomplete fermentation, etc., and achieve the effects of improving growth conditions, speeding up the decomposing process, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific preparation process of the multi-temperature segment compound strain is as follows:

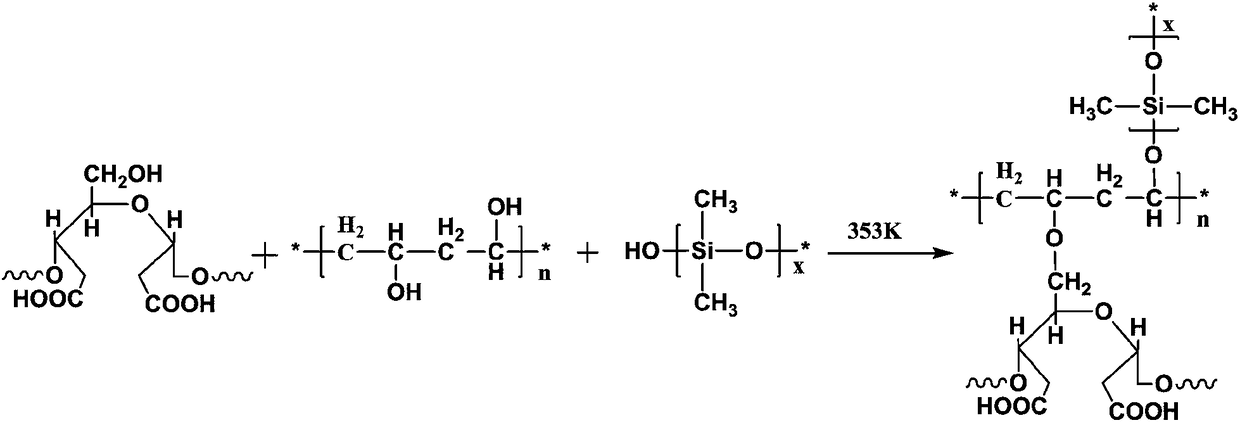

[0032] Step 1: Take 1kg of polyvinyl alcohol with a low degree of polymerization and add it to 16kg of hot water at a temperature of 90°C, stir and dissolve, then cool down to 50°C, then add 1.2kg of oxidized starch, stir and mix evenly to obtain a fixative slurry;

[0033] Step 2: Add 0.53 kg of hydroxy silicone oil to 1 kg of the fixative slurry prepared in the first step, heat up to 80 ° C, stir and mix for 30 min, and then cool down to room temperature to obtain a high-temperature resistant fixative;

[0034] Step 3: Add 1kg of high-temperature-resistant fixative into the three-necked flask, place the three-necked flask in an ice-water bath at 0-5°C, weigh 0.08kg of frozen bacillus and 0.1kg of frozen mold and add it to the three-necked flask at the same time, stir Mix evenly, add 0.63kg zeolite powder to it, stop vacuuming after 2 hours and gradually warm up to room t...

Embodiment 2

[0038] The specific preparation process of the multi-temperature segment compound strain is as follows:

[0039] Step 1: Take 1kg of polyvinyl alcohol with a low degree of polymerization and add it to 16kg of hot water at a temperature of 90°C, stir and dissolve, then cool down to 50°C, then add 1.2kg of oxidized starch, stir and mix evenly to obtain a fixative slurry;

[0040] Step 2: Add 0.55 kg of hydroxy silicone oil to 1 kg of the fixative slurry prepared in the first step, raise the temperature to 80 ° C, stir and mix for 30 min, and then cool down to room temperature to obtain a high temperature resistant fixative;

[0041] Step 3: Add 1kg of high-temperature-resistant fixative into the three-necked flask, place the three-necked flask in an ice-water bath at 0-5°C, weigh 0.08kg of frozen bacillus and 0.1kg of frozen mold and add it to the three-necked flask at the same time, stir Mix evenly, add 0.69kg zeolite powder to it, stop vacuuming after 2 hours and gradually war...

Embodiment 3

[0045] A kind of concrete preparation process of bio-organic fertilizer is as follows:

[0046] In the first step, 85kg of crop straw is crushed into particles with a particle size of less than 3cm×3cm×3cm, and at the same time, the crushed crop straw is poured into a fermentation tank, and a certain amount of water is added to it to ensure that the water content is equal to the straw content. 60-65%;

[0047] In the second step, 1.3kg of yeast strains and 1.2kg of Bacillus licheniformis are activated and inoculated, and the culture is expanded, and then the cultured strains are sprayed in the fermenter, and the temperature is controlled to ferment at 40°C for 8-9 days. The stirring mechanism in the medium fermenter is always in a state of stirring to realize a cellulose degradation fermentation;

[0048] In the third step, add 39kg of animal manure, 24kg of cake and 20kg of biogas residue into the fermenter, and add a certain amount of water at the same time to keep the mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com