A method for optimizing performance of calcium-based geopolymer by multi-component composite powder

A multi-component composite and optimization method technology, applied in cement production, etc., can solve the problems of alkali slag cement stone shrinkage and brittleness, durability impact, low cement stone strength, etc., to optimize the cement stone pore structure and reduce the total porosity , reduce the effect of refining the aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

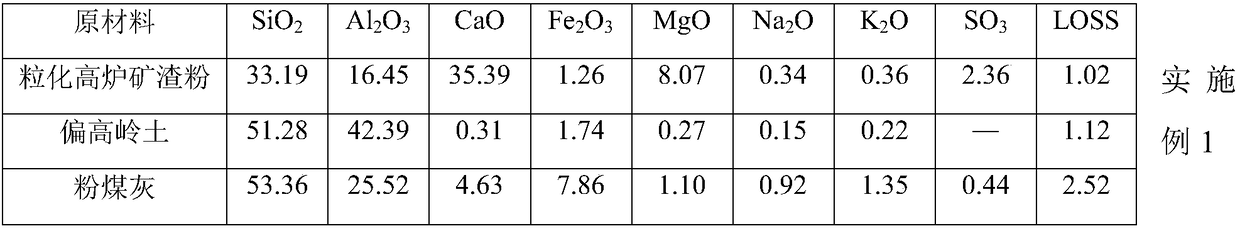

Examples

Embodiment 2

[0047] Different forms of Na 2 SiO 3 Effect on compressive strength of slag slurry, solid Na 2 SiO 3 The modulus is 1, the high modulus liquid Na 2 SiO 3 Adjust its modulus to 1 with NaOH, Na 2 SiO 3 The dosages are 2%, 4%, 6%, 8%, and 10%, respectively, the granulated blast furnace slag is used as the cementitious material, the water-cement ratio is 0.45 for experiments, and the curing is carried out under standard conditions.

[0048] The preparation steps of the calcium-based polymer are the same as in Example 1.

[0049] The experimental results are shown in Table 3.

[0050] Table 3 Na in different forms 2 SiO 3 Influence on the compressive strength of slag slurry.

[0051]

[0052] It can be seen from Table 3 that the same modulus is 1, and the liquid Na 2 SiO 3 The excitation effect on slag powder is due to the solid Na 2 SiO 3 . Solid Na 2 SiO 3 In the case of a dosage of 2%-4%, there is no compressive strength for 3 days and 7 days, and very low co...

Embodiment 3

[0054] Liquid Na with different modulus 2 SiO 3 The impact on the compressive strength of the slag slurry, according to the calculated ratio, in the commercially available liquid Na 2 SiO 3 Add NaOH to make liquid Na with modulus 0.8, 1.0, 1.2, 1.4, 1.6 respectively 2 SiO 3 . Liquid Na 2 SiO 3 The dosage accounts for 6% of the mass ratio of the granulated blast furnace slag powder, the water-binder ratio is 0.45, and it is cured under standard conditions.

[0055] The experimental results are shown in Table 4.

[0056] Table 4 Liquid Na with different modulus 2 SiO 3 Influence on the compressive strength of slag slurry.

[0057]

[0058] At 6% dosage, the compressive strength of slag clean slurry varies with liquid Na 2 SiO 3 Modulus decreases and increases. At 3 days and 7 days, the compressive strength varies with liquid Na 2 SiO 3 The decrease in modulus increases steadily. However, the increase in the range of 0.8-1.0 is not large. On the 28th day, the ...

Embodiment 4

[0060] Liquid Na in different amounts 2 SiO 3 The impact on the compressive strength of the slag slurry, according to the calculated ratio, in the commercially available liquid Na 2 SiO 3 Add NaOH to prepare liquid Na with a modulus of 1.0 2 SiO 3 . Liquid Na 2 SiO 3 The dosage is 4%, 6% and 8% in the mass ratio of granulated blast furnace slag powder, the water-binder ratio is 0.45, and it is cured under standard conditions.

[0061] The experimental results are shown in Table 5

[0062] Table 5 Liquid Na in different dosages 2 SiO 3Effect on compressive strength of slag slurry

[0063]

[0064] It can be seen from Table 5 that with Na 2 SiO 3 With the increase of the dosage, the compressive strength of slag net slurry also increases; Na 2 SiO 3 After the dosage increases to a certain extent, the compressive strength of the slag clean slurry increases less; 2 SiO 3 In the case of different dosages, the compressive strength of slag clean slurry develops stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com