Automatic packaging system for steel rail fastening assemblies

An automatic packaging and component technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of low work efficiency, waste of manpower and material resources, time-consuming and labor-intensive problems, save manpower and material resources, improve product qualification rate and production safety, Avoid the effects of packaging failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

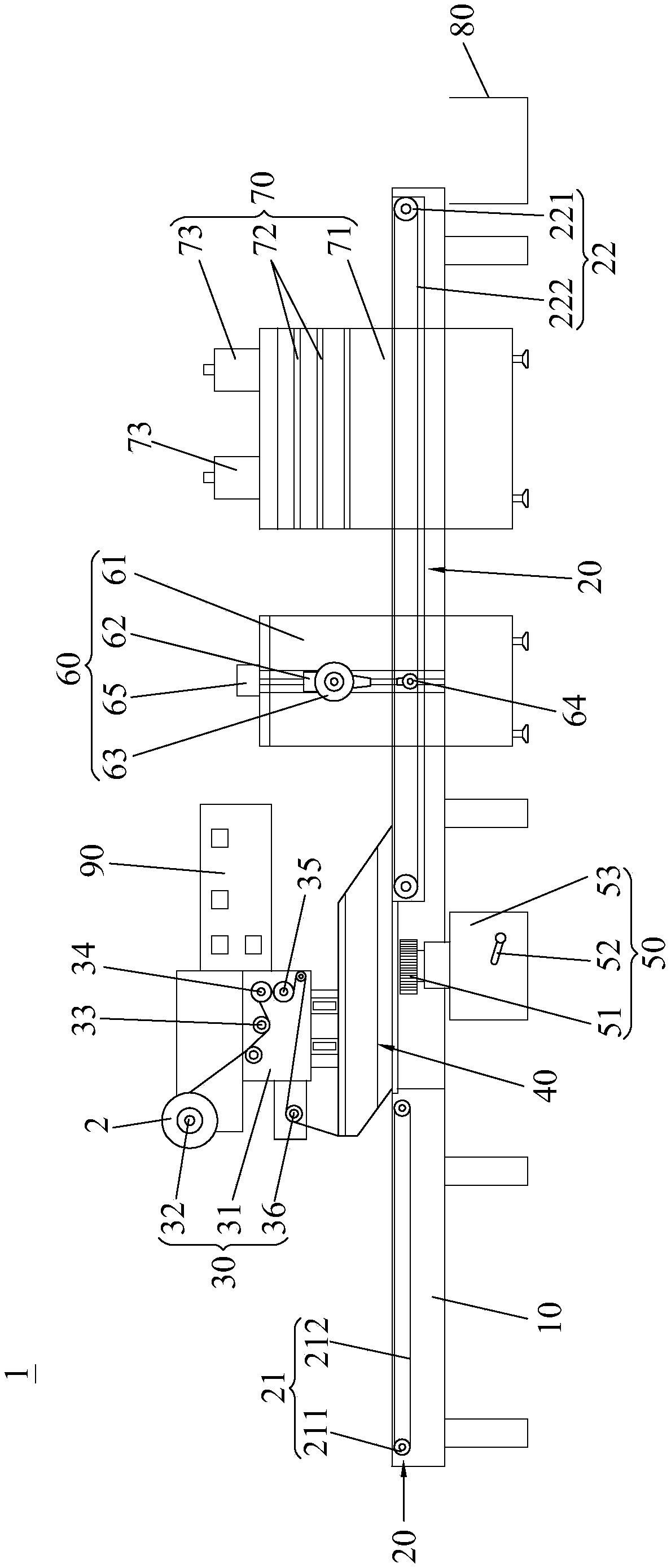

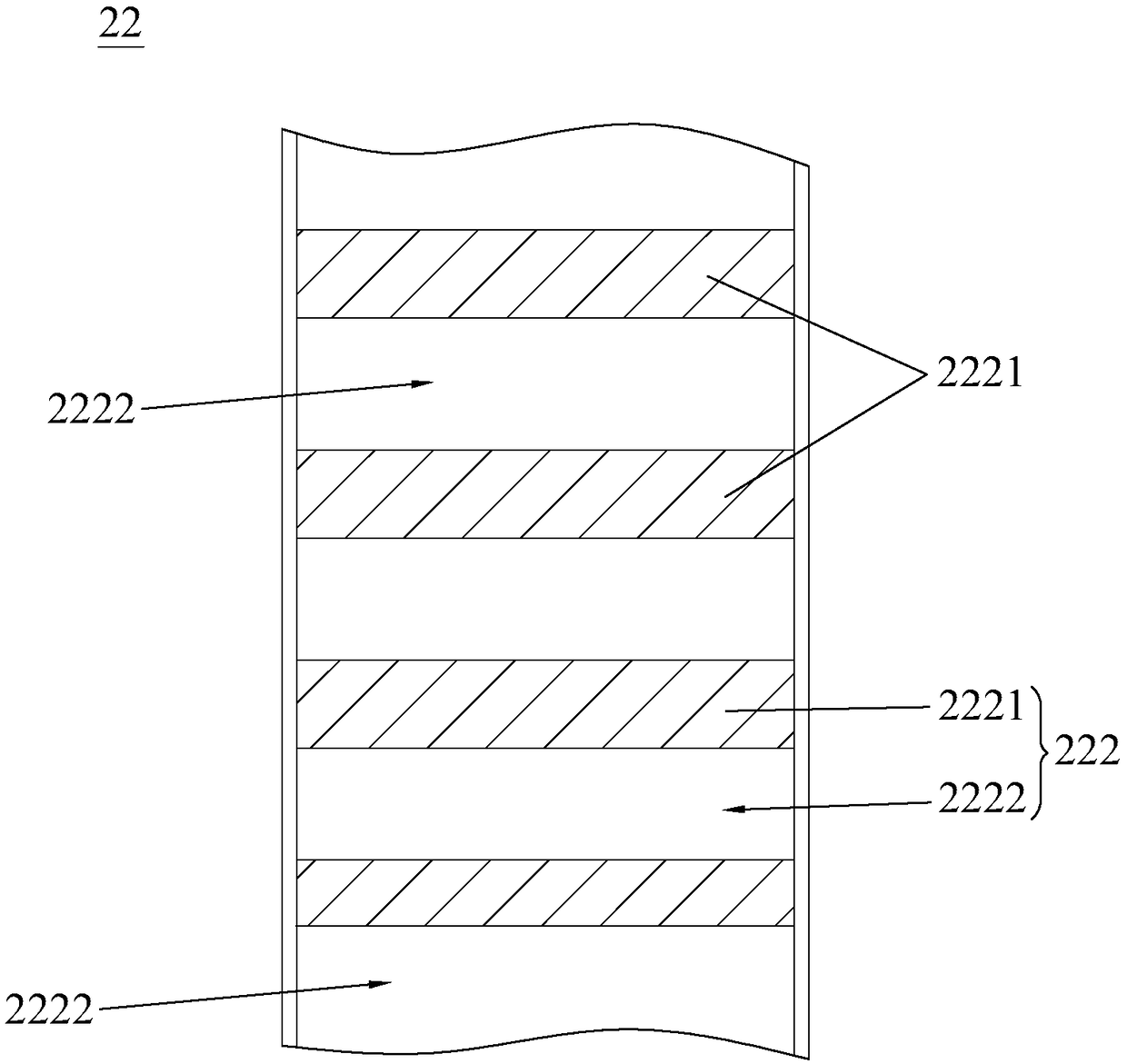

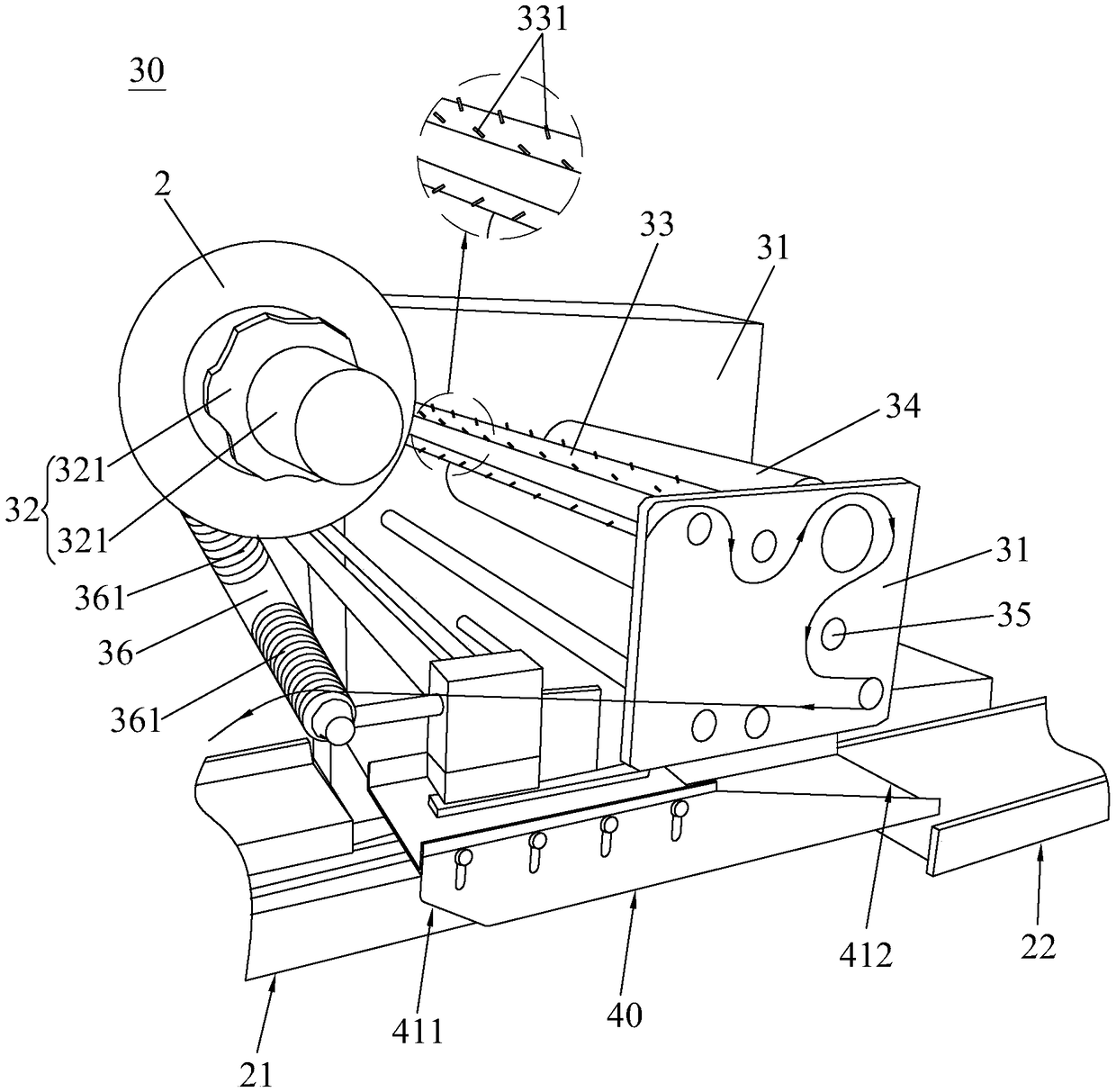

[0029] Such as Figure 1-Figure 10 As shown, the automatic packaging system 1 for rail fastening components provided by the present invention includes a frame 10 , a conveying device 20 , a film stretching device 30 , a bag making device 40 , a longitudinal sealing device 50 , a transverse cutting device 60 and a shrinking device 70 . Wherein, the conveying device 20 is arranged on the frame 10, the bag making device 40, the longitudinal sealing device 50, the transverse cutting device 60, and the shrinking device 70 are arranged along the conveying direction of the conveying device 20 in sequence, and the film stretching device 30 is arranged on the bag making device 40 Above, the film supporting device 30 is used to install the packaging film 2, and the bag making device 40 is used to support the packaging film 2 to fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com