Preparation method of octahedral 3D printed PLGA/hydroxyapatite cervical interbody fusion cage, product and application thereof

A technology of hydroxyapatite and intervertebral fusion, which is applied in the field of medical materials, can solve the problems of patients with foreign bodies, large opening trauma, cumbersome operation, etc., and achieve the effects of convenient implantation, accelerated fusion, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

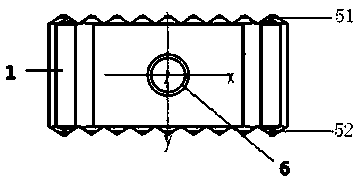

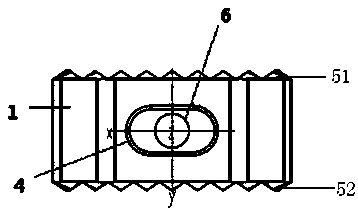

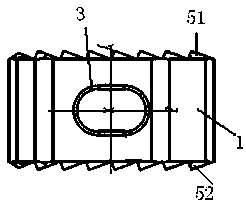

[0046]A preparation method of an octahedral 3D printed PLGA / hydroxyapatite cervical intervertebral fusion device, using 3D printing technology, and polylactic acid-polyglycolic acid (PLGA) copolymer as the biomaterial of the cervical intervertebral fusion device Stent main body 1, preparing biodegradable nano-hydroxyapatite composite fusion cage stent by fused deposition forming 3D printing, includes the following steps:

[0047] (1) Preparation of PLGA / hydroxyapatite composite:

[0048] Cut the PLGA with a molecular weight of 200,000 into small pieces, put it into the printing chamber of the 3D plotter preheated at 140°C, the stacking height between the 3D layers is 0.5 mm, and 3D print to make the neck fusion device;

[0049] (2) Preparation of cervical intervertebral fusion cage model:

[0050] see Figure 1-Figure 6 , use CAD software to edit the finite element model based on the real anatomical model of the finite element human cervical spine, save it as a stl standard ...

Embodiment 2

[0058] Similar to Example 1, except that the nano-hydroxyapatite powder in PLGA / hydroxyapatite is 10% by mass.

[0059] First, cut PLGA (200,000 molecular weight) into small pieces and fill them into the cavity of a Haake rheometer preheated to 140 degrees Celsius, add 10% by mass fraction of nano-hydroxyapatite powder in stages, and mix thoroughly for about After 1 hour, after cooling to 70°, disassemble the cavity and take out the material. Cut the mixed material into small pieces with scissors and stuff them into the printing chamber of the 3D plotter, set the temperature to 140 degrees Celsius for 30 minutes, set the stacking height between layers to 0.5 mm, and print to make the neck fuser.

[0060] For cervical fusion cage data model, see Figure 1-Figure 6 , this embodiment mainly includes that the main body 1 has a similar octagonal cylinder structure, and the asymmetrical octagonal cylinder shape is beneficial to the surgical operation of cervical fusion cage implant...

Embodiment 3

[0067] Similar to Example 1, except that the nano-hydroxyapatite powder in PLGA / hydroxyapatite is 20% by mass.

[0068] First, cut PLGA (200,000 molecular weight) into small pieces and fill them into the cavity of a Haake rheometer preheated to 140 degrees Celsius, add 20% by mass fraction of nano-hydroxyapatite powder in stages, and mix thoroughly for about After 1 hour, after cooling to 70°, disassemble the cavity and take out the material. Cut the mixed material into small pieces with scissors and stuff them into the printing chamber of the 3D plotter, set the temperature to 140 degrees Celsius for 30 minutes, set the stacking height between layers to 0.5 mm, and print to make the neck fuser.

[0069] For cervical fusion cage data model, see Figure 1-Figure 6 , this embodiment mainly includes that the main body 1 has a similar octagonal cylinder structure, and the asymmetrical octagonal cylinder shape is beneficial to the surgical operation of cervical fusion cage implant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com