Portable wheel-rail lateral force calibration device

A calibration device and lateral force technology, applied in hydraulic/pneumatic measurement and other directions, can solve the problems of complicated operation, vehicle transportation, and poor calibration value accuracy, and achieve the effect of high test accuracy, high operation efficiency and intuitive reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

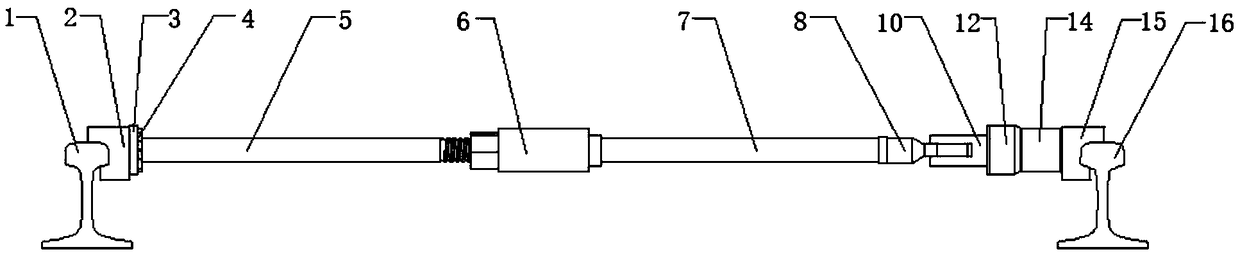

[0033] Such as figure 1 As shown, a portable wheel-rail lateral force calibration device includes auxiliary rail chuck 2, left connecting rod 5, middle threaded sleeve 6, right connecting rod 7, joint bearing 8, bearing seat 10, thrust bearing 11, bearing pressure Ring 12, guide post 13, pressure sensor 14, main rail chuck 15; the left end of the left end of the left connecting rod 5 and the left end of the right connecting rod 7 all have external threads, by cooperating with the internal threads of the middle threaded sleeve 6, Spliced into an integral support rod as a main structure of the device; the left end of the left connecting rod 5 is welded to a flange 3, and the auxiliary rail chuck 2 is connected by a screw 4; the right end of the right connecting rod 7 is connected by a screw thread The rod end of the spherical plain bearing 8; the right end of the spherical plain bearing 8 is fixed on the bearing seat 10 through the hexagon socket bolt 9; the guide post 13 is i...

Embodiment 2

[0043] Such as Figure 7 As shown, the intermediate drive device is changed to piston rod drive 6, and other items are the same as those in Implementation 1.

Embodiment 3

[0045] Such as Figure 8 As shown, the intermediate drive device is changed to shake the screw drive 6, and other items are the same as in Implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com