Mold for shaping middle part of cross member

A technology for forming molds and cross bars, which is applied in the field of forming molds in the middle of cross bars, can solve problems such as easy deviation of workpiece positioning, easy changes in precision, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

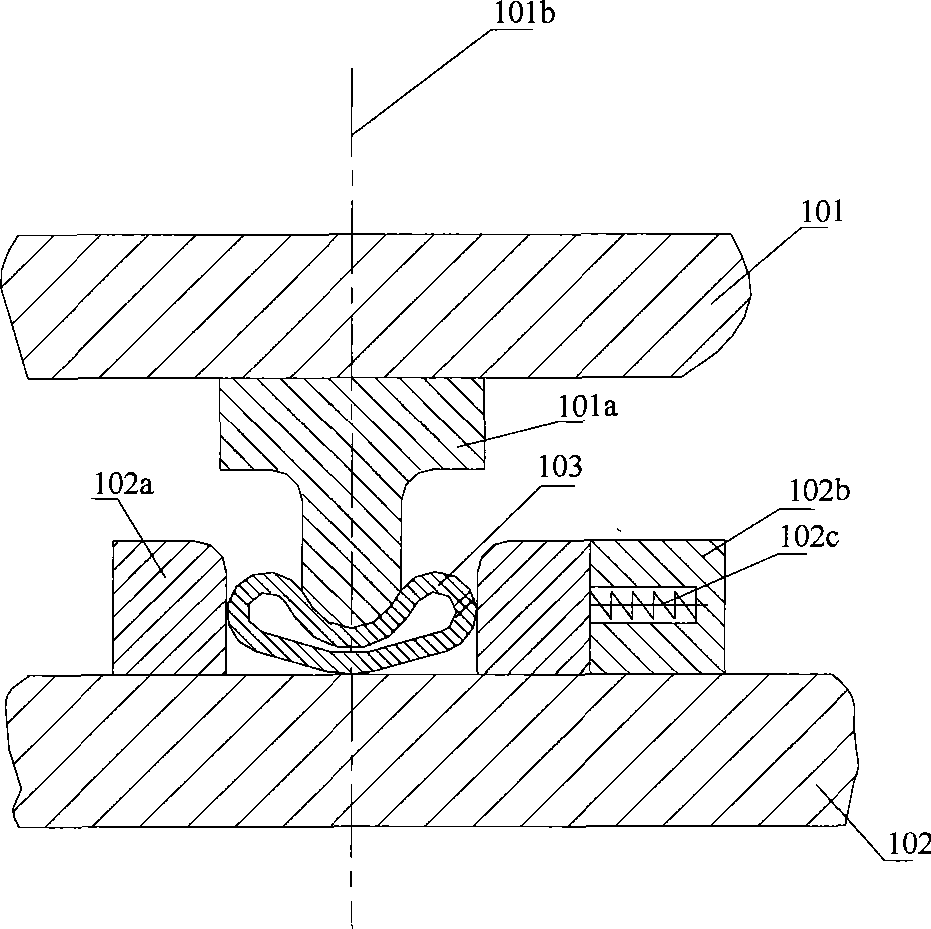

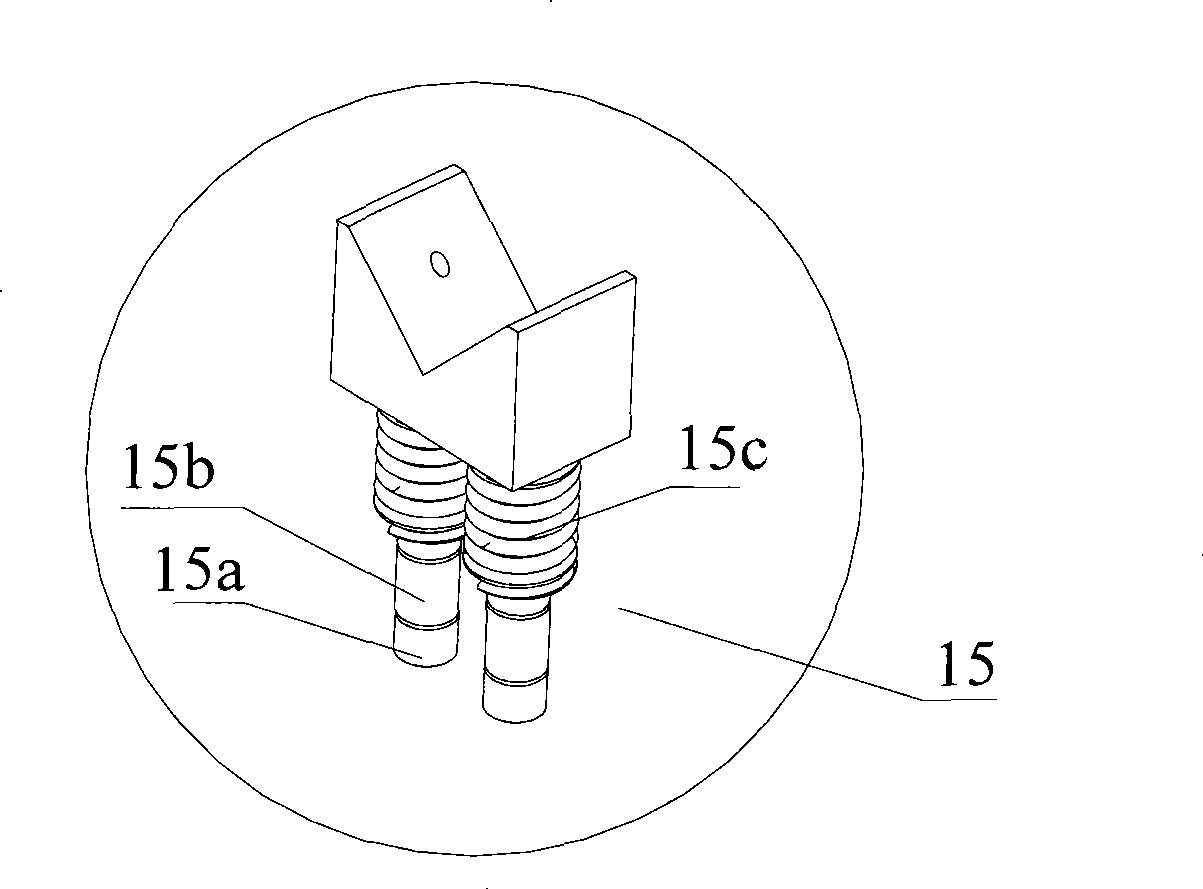

[0027] See figure 2 and image 3 As shown, it is a schematic diagram of a specific embodiment of the cross bar middle forming die provided by the present invention, figure 2 The exploded schematic diagram of the lower mold of the cross bar middle forming mold provided by the present invention, image 3 It is an overall disassembled schematic diagram of the forming mold for the middle part of the cross bar provided by the present invention. like figure 2 As shown, in the forming mold, a lower template 1 connected with a hydraulic device is included, and a lower mold base 12 is fixedly installed on the lower template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com