Super-resolution three-dimensional shape measurement method based on optical tweezers dielectric microspheres

A technology of three-dimensional topography and measurement method, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of narrow measurement field of view, image deformation, unable to obtain the best imaging quality, etc., to expand the imaging field of view, improve the Detection efficiency and the effect of realizing high-precision super-resolution 3D topography measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

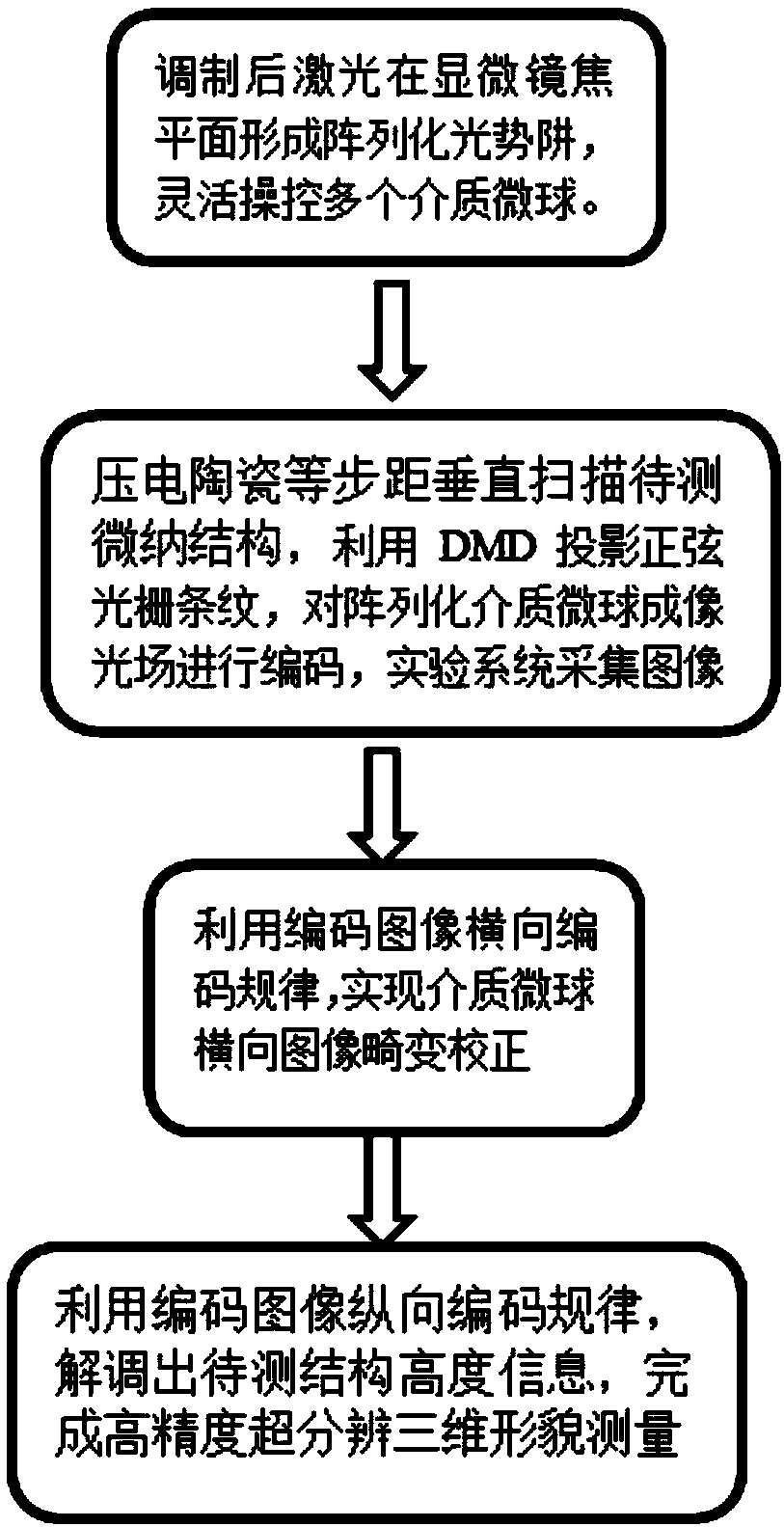

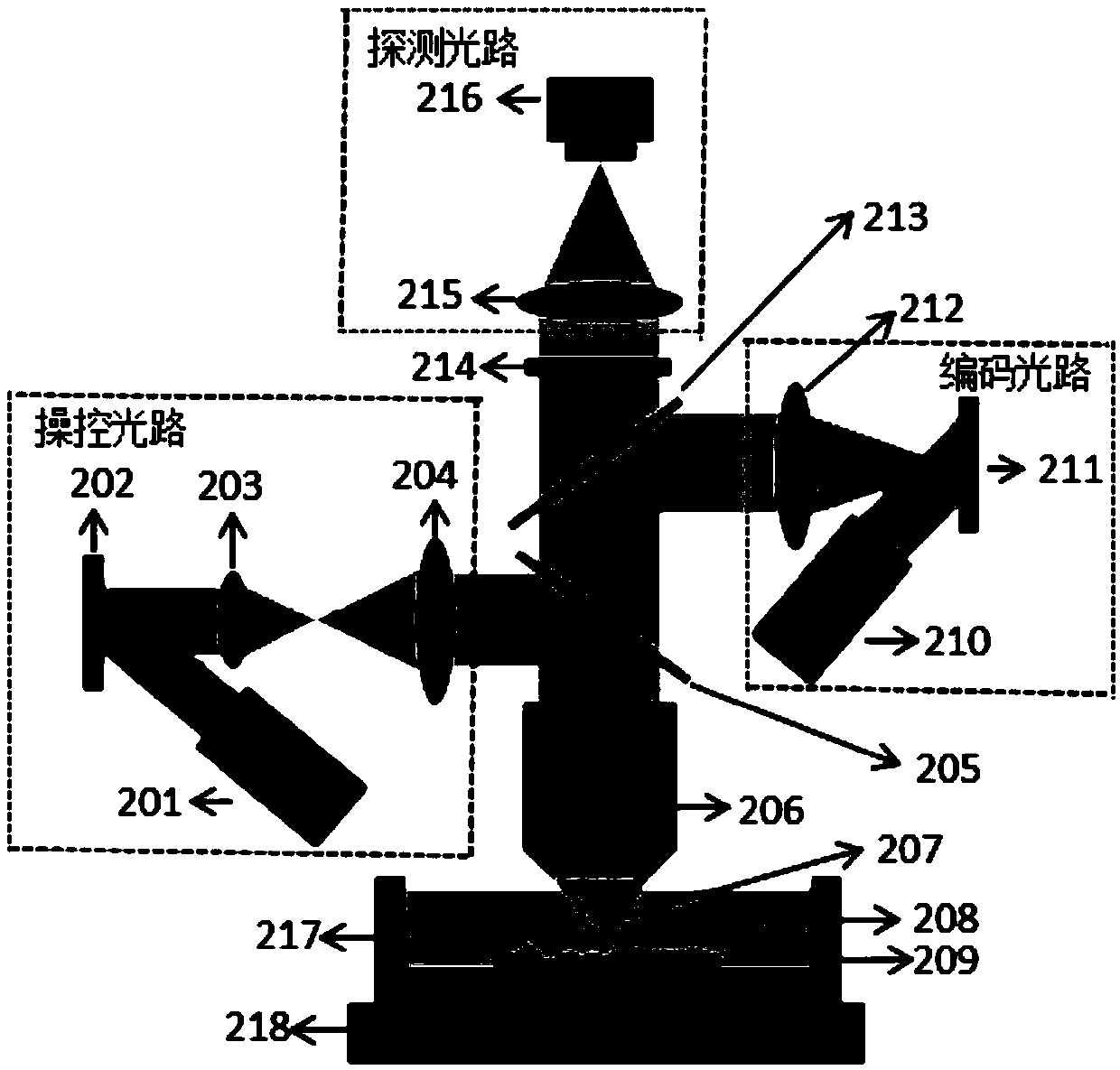

[0032] Such as figure 1 and figure 2 As shown, this super-resolution three-dimensional reconstruction measurement method based on optical tweezers dielectric microspheres can flexibly control the position of the dielectric microspheres, and at the same time, high-precision super-resolution three-dimensional measurement can be realized through optical field encoding.

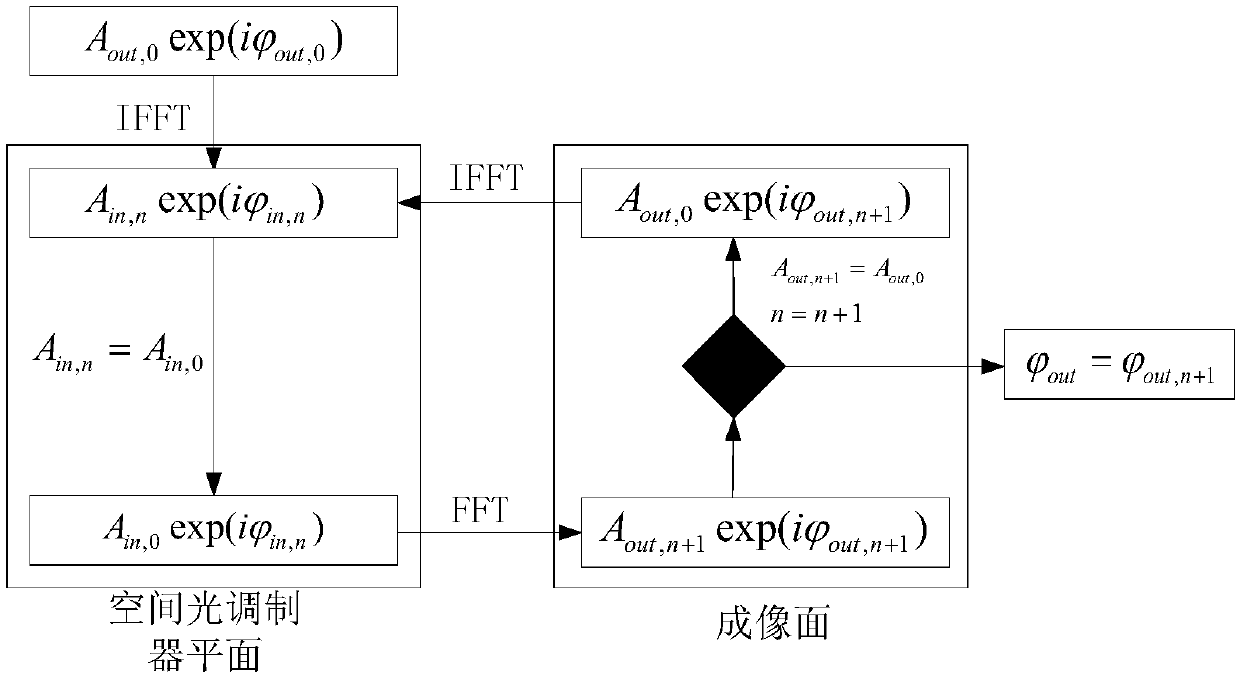

[0033] Step S1: In the control optical path, load the pre-calculated desired phase distribution onto the phase-only spatial light modulator, and the collimated and expanded laser beam is modulated and reflected by the pure-phase spatial light modulator, and then passes through the objective lens after beam shrinkage Focusing forms an arrayed optical potential well, so that multiple medium microspheres can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com