Method for preparing Al-Pd-Fe two-dimensional quasicrystal particles

An al-pd-fe, quasicrystal technology, applied in the field of preparation of quasicrystal particles, can solve the problems of complex process, high operation requirements, and many equipment needs, and achieves simple process operation, strong operability, and less time consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

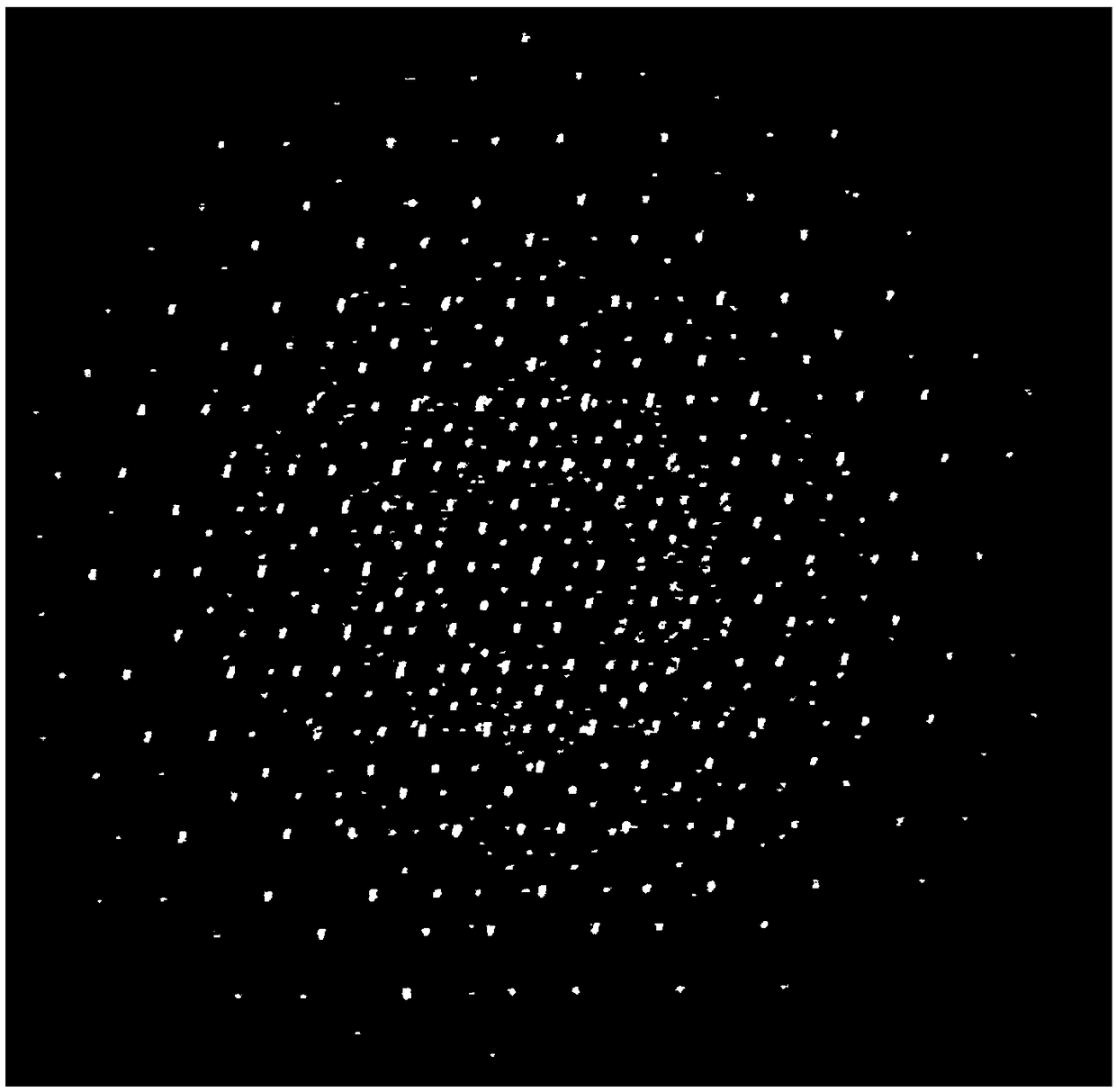

Image

Examples

Embodiment 1

[0020] (1) Calculate and weigh high-purity Al powder, Pd powder, Fe powder raw material according to atomic proportion, its weight is respectively 0.9701g, 0.7617g, 0.2683g (according to Al 75 PD 15 Fe 10 Weighing), the above powder is placed in a mortar, fully ground and mixed evenly, and placed in a graphite crucible with an inner diameter of Φ20mm, and pressurized at 1MPa in a hydraulic tablet press for 100s to obtain a sheet pre-pressed sample with a diameter of Φ20mm;

[0021] (2) The graphite crucible is a tubular furnace body with a height of 40mm and an outer diameter of Φ50mm and an inner diameter of Φ20mm. Both ends are sealed with graphite plugs of Φ20mm and a thickness of 20mm. The graphite furnace is covered with a layer of carbon paper. The carbon paper is 63mm long and 40mm wide. On the inner side of the furnace, Φ20mm carbon paper is used at both ends to separate the graphite plug from the sample to prevent the sample from reacting with the graphite furnace un...

Embodiment 2

[0027] (1) Calculate and weigh high-purity Al powder, Pd powder, Fe powder raw material according to atomic ratio, its weight is respectively 0.7820g, 1.1018g, 0.1157g (according to Al 70 PD 25 Fe 5 Weighing), the above-mentioned powder is placed in a mortar, fully ground and mixed evenly, and placed in a graphite crucible with an inner diameter of Φ20mm, and pressurized at 1.5Mpa in a hydraulic tablet press for 80s to obtain a sheet pre-pressed sample with a diameter of Φ20mm;

[0028] (2) The graphite crucible is a tubular furnace body with a height of 40mm and an outer diameter of Φ50mm and an inner diameter of Φ20mm. Both ends are sealed with graphite plugs of Φ20mm and a thickness of 20mm. The graphite furnace is covered with a layer of carbon paper. The carbon paper is 63mm long and 40mm wide. On the inner side of the furnace, Φ20mm carbon paper is used at both ends to separate the graphite plug from the sample to prevent the sample from reacting with the graphite furna...

Embodiment 3

[0034] (1) Calculate and weigh high-purity Al powder, Pd powder, Fe powder raw material according to atomic proportion, its weight is respectively 1.0310g, 0.5422g, 0.4268g (according to Al 75 PD 10 Fe 15 Weighing), the above powder is placed in a mortar, fully ground and mixed evenly, and placed in a graphite crucible with an inner diameter of Φ20mm, and pressurized at 2Mpa in a hydraulic tablet press for 60s to obtain a thin sheet pre-pressed sample with a diameter of Φ20mm;

[0035](2) The graphite crucible is a tubular furnace body with a height of 40mm and an outer diameter of Φ50mm and an inner diameter of Φ20mm. Both ends are sealed with graphite plugs of Φ20mm and a thickness of 20mm. The graphite furnace is covered with a layer of carbon paper. The carbon paper is 63mm long and 40mm wide. On the inner side of the furnace, Φ20mm carbon paper is used at both ends to separate the graphite plug from the sample to prevent the sample from reacting with the graphite furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com