Intelligent building coating for purifying air and preparation method of intelligent building coating

A technology for intelligent building and air purification, applied in coatings and other directions, can solve the problems of easy failure and shedding, low application efficiency, easy to agglomerate, etc., achieve good exterior decoration effect, purify atmospheric air, and overcome the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 36kg of titanium dioxide colloid with a mass concentration of 15% to 51kg of aminated polyurethane emulsion, add 13kg of large-diameter mica powder, disperse evenly, raise the temperature to 56°C for 1.5h, and then spray dry to form titanium dioxide, and mix with polyurethane and large-diameter mica The powder is assembled into spherical particles; then 26kg spherical particles are mixed with 50kg acrylic acid emulsion, 7kg cellulose, 3kg metal azo pigment, 3kg sodium dodecylbenzenesulfonate, 7kg dimethylformamide, 2kg acid phosphate amine salt, 2kg of biphenyl mixed to prepare an air-purifying smart building coating.

[0030] Test Methods:

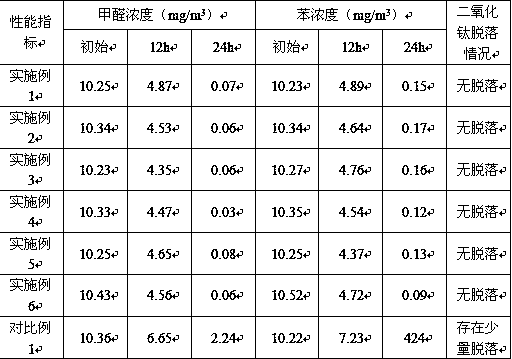

[0031] Formaldehyde and benzene purification test: the architectural coatings prepared by the present invention are respectively coated on 10m 3 Formaldehyde test room and benzene test room, the average thickness of the coating is 0.5mm, the incandescent lamp of lx20000 is used as the light source, the test temperature is 25 ℃...

Embodiment 2

[0035] Add 30kg of titanium dioxide colloid with a mass concentration of 15% to 58kg of aminated polyurethane emulsion, add 12kg of large-diameter mica powder, disperse evenly, heat up to 50°C for 2 hours, and then spray dry to form titanium dioxide, and mix with polyurethane and large-diameter mica powder Assemble into spherical particles; then mix 20kg spherical particles with 63kg acrylic emulsion, 5kg cellulose, 2kg heterocyclic pigments, 2kg sodium dodecylbenzenesulfonate, 5kg dimethylformamide, 2kg alkylsuccinimide , 1kg o-phenylphenol mixed to prepare an intelligent building coating for air purification.

[0036] The test method is consistent with Example 1, and the obtained data are shown in Table 1.

Embodiment 3

[0038]Add 40kg of titanium dioxide colloid with a mass concentration of 15% to 45kg of aminated polyurethane emulsion, add 15kg of large-diameter mica powder, disperse evenly, heat up to 60°C for 1 hour, and then spray dry to form titanium dioxide, and mix with polyurethane and large-diameter mica powder Assembled into spherical particles; then 30kg of spherical particles and 36kg of acrylic acid emulsion, 10kg of cellulose, 5kg of fused ring ketone pigments, 4kg of sodium dodecylbenzenesulfonate, 10kg of dimethylformamide, 3kg of dimethyl sulfoxide, 2K2-Pyridinethiol-1-Zinc Oxide Mixture to Prepare Air-Cleaning Smart Architectural Coatings.

[0039] The test method is consistent with Example 1, and the obtained data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com