Preparation method of antistatic powder coating material

A powder coating and antistatic technology, applied in powder coatings, conductive coatings, antifouling/underwater coatings, etc., can solve problems such as partial discharge loss, achieve enhanced quality, improved uniformity and stability, and enhanced dispersion compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

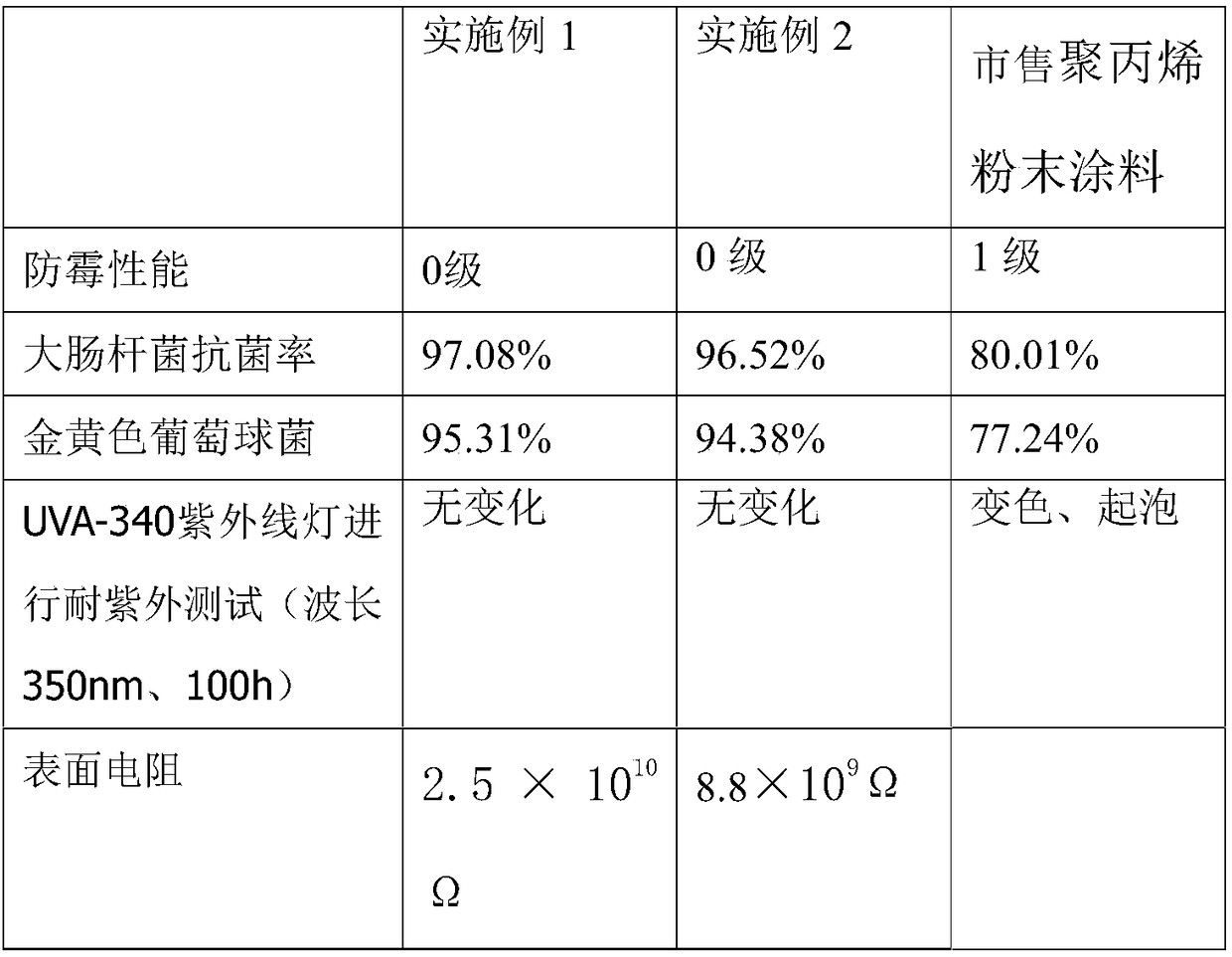

Examples

Embodiment 1

[0015] A preparation method of antistatic powder coating, comprising the following steps:

[0016] (1) Get 2 parts by weight of triglycidyl isocyanurate and 16 parts by weight of acetylene carbon black and mix them, add them to dimethyl carbonate with 10 times the weight of the mixture, ultrasonically for 1 hour, and raise the temperature to 70°C. Add 0.4 parts by weight of oleic acid diethanolamide, heat and stir for 20 minutes to obtain an amide dispersion;

[0017] (2) 10 parts by weight of stearic acid is heated and softened, mixed with 8 parts by weight of triethanolamine, sent into the reaction kettle, added p-toluenesulfonic acid of 1% by weight of the mixture, and fed with nitrogen to adjust the reaction The temperature of the kettle was 165°C, and the reaction was stirred for 5 hours to obtain the ester amine;

[0018] (3) Take the above-mentioned ester amine, add it to the above-mentioned amide dispersion, stir evenly, send it into the reaction kettle, pass in nitro...

Embodiment 2

[0022] A preparation method of antistatic powder coating, comprising the following steps:

[0023] (1) Get 4 parts by weight of triglycidyl isocyanurate and 20 parts by weight of acetylene carbon black and mix them, add them to dimethyl carbonate with 13 times the weight of the mixture, ultrasonically for 2 hours, and raise the temperature to 75°C. Add 1 weight part of oleic acid diethanolamide, heat and stir for 30 minutes to obtain an amide dispersion;

[0024] (2) 14 parts by weight of stearic acid is heated and softened, mixed with 9 parts by weight of triethanolamine, sent into the reaction kettle, added p-toluenesulfonic acid of 3% by weight of the mixture, and fed with nitrogen to adjust the reaction The temperature of the kettle is 180°C, and the reaction is stirred for 6 hours to obtain the ester amine;

[0025] (3) Take the above-mentioned ester amine, add it to the above-mentioned amide dispersion, stir evenly, send it into the reaction kettle, feed nitrogen gas, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com