Device for Continuously Separating Hexachloroethane from Perchlorethylene Solid Waste

A technology of hexachloroethane and tetrachloroethylene, which is applied in the field of continuous separation of hexachloroethane from solid waste of tetrachloroethylene, can solve the problems of low separation efficiency, large pollution of the working environment, and long intermittent reaction time, and achieve Increase the sealing area, improve the separation effect, and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

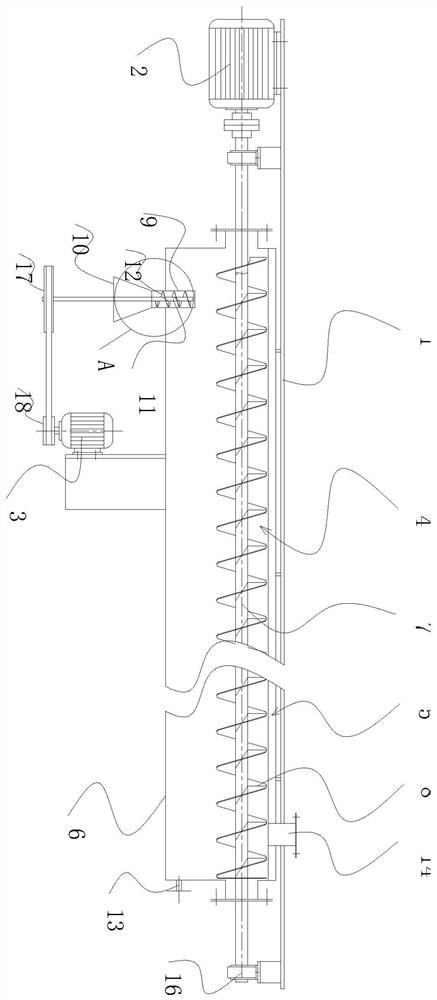

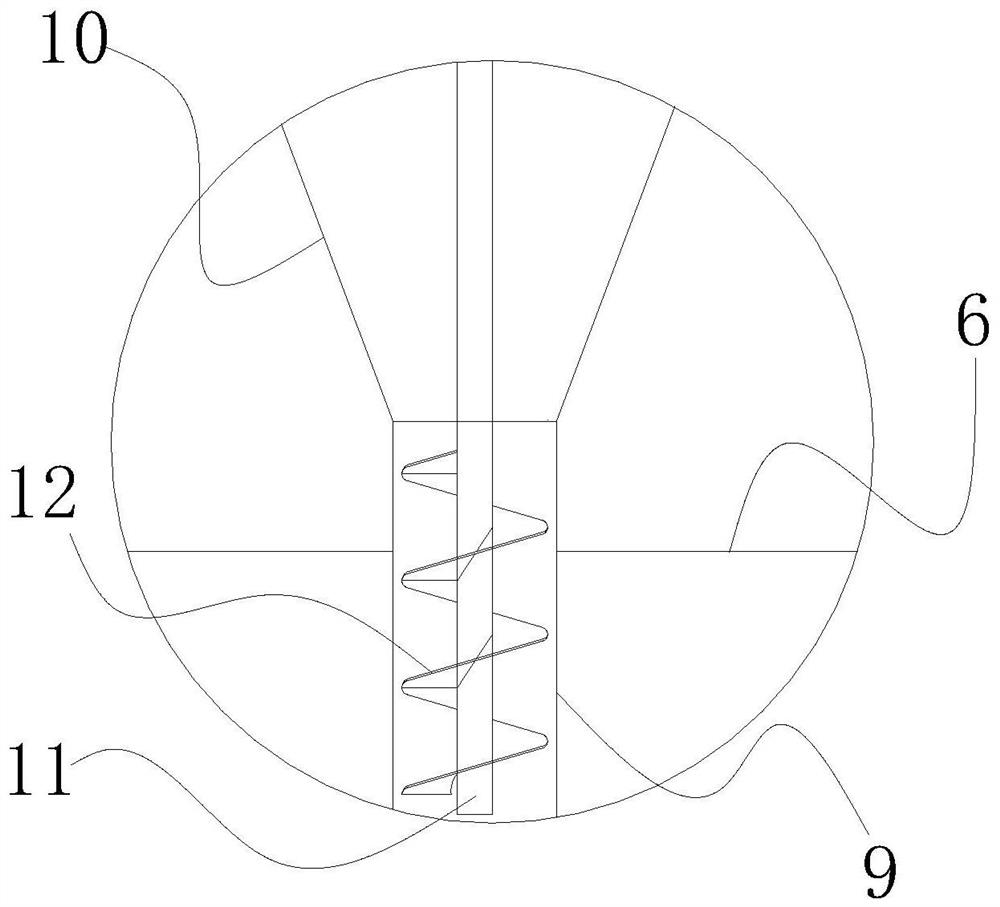

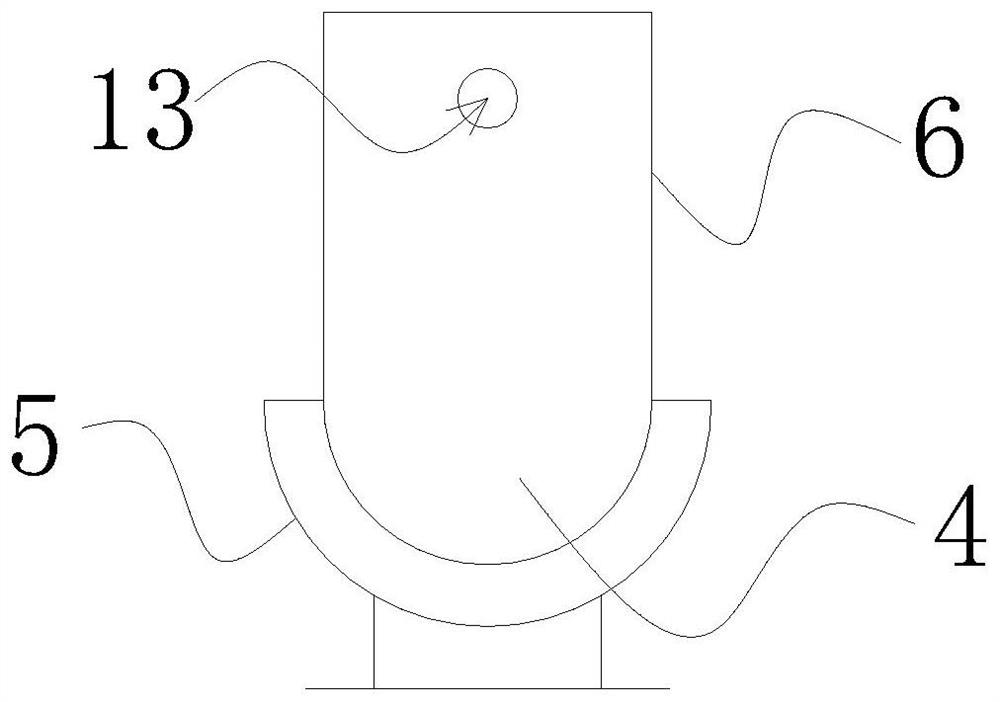

[0022] see Figure 1 to Figure 3 , is a specific embodiment of a device for continuously separating hexachloroethane from solid tetrachlorethylene waste. The device for continuously separating hexachloroethane from tetrachlorethylene solid waste includes a base 1 , a speed-regulating motor 2 , a driving motor 3 , and a strip groove 4 installed on the base 1 . The cross-section of the strip groove 4 is semicircular and the opening is upward, and the outer wall of the strip groove 4 is covered with a heating jacket 5, and the opening of the strip groove 4 is sealed by a sealing cover 6, the The cross-section of the sealing cover 6 is rectangular, and the depth of the cavity of the sealing cover 6 is greater than the depth of the cavity of the strip groove 4. In this embodiment, the strip groove and the sealing cover are all made of stainless steel plates. The groove extends along the horizontal direction, and the sealing cover is fixed on the opening of the strip groove by weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com