Numerical control grinding machine for caliper periphery

A technology of CNC grinding machine and caliper, which is applied in the direction of grinding machine, grinding bed, grinding machine parts, etc., can solve the problems of low production efficiency, backward production technology of caliper and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

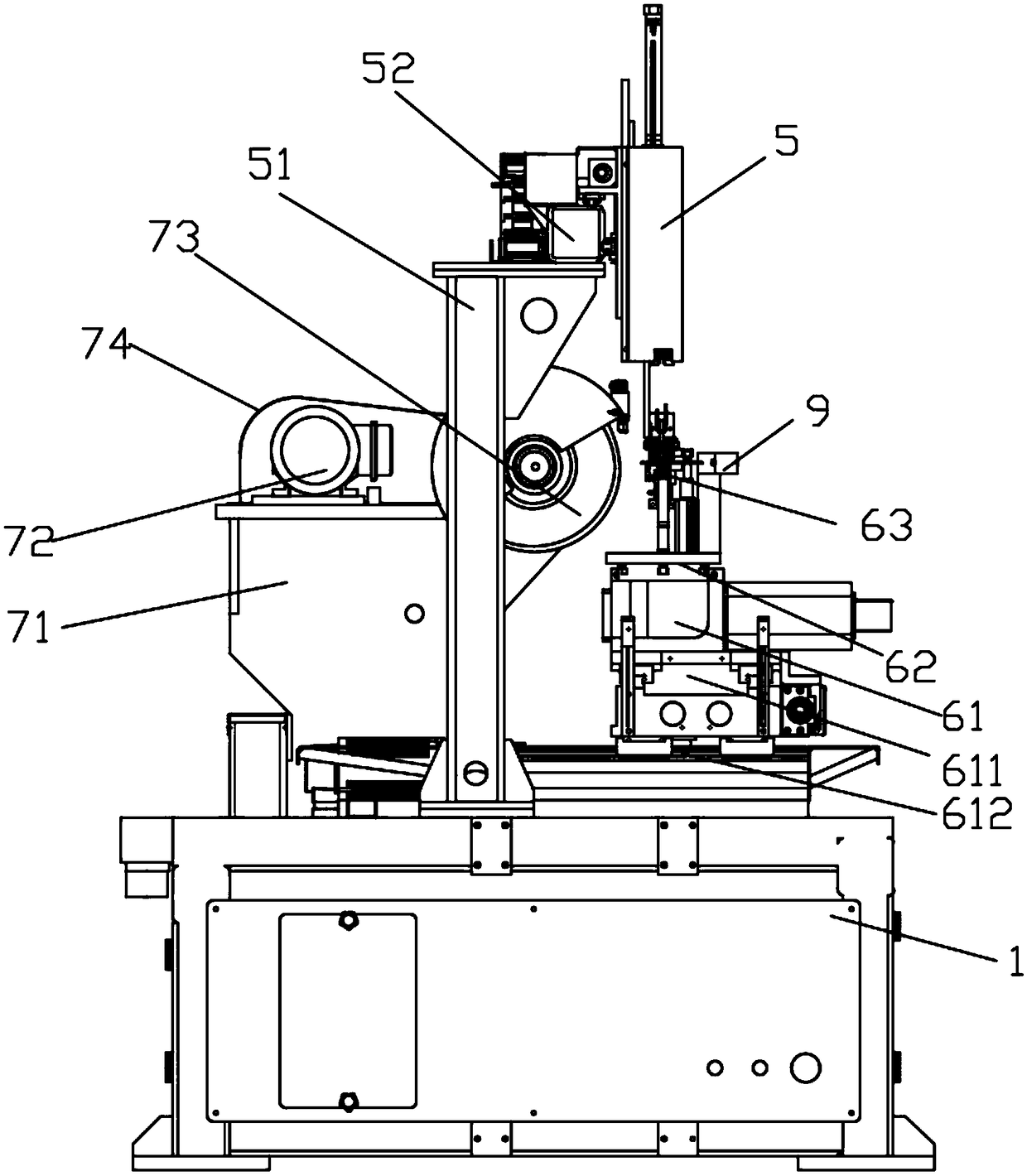

[0024] Embodiment: A numerically controlled grinder for the periphery of a caliper, comprising a grinder body 1, a feeding device 2, several grinding stations 3 and a blanking device 4, and the feeding device and the blanking device are symmetrically installed on the sides of the grinder body On both sides, the grinding station is located in the grinding machine body;

[0025] The grinding station includes a manipulator 5 for picking and placing the caliper, a kinematic mechanism 6 for transporting the caliper to a grinding position, and a grinding mechanism 7 for grinding the caliper. The manipulator moves and is installed on the grinder body. The mechanisms are all fixedly installed in the grinding machine body, the manipulator is located above the moving mechanism, and the grinding mechanism is located behind the moving mechanism.

[0026] The movement mechanism includes a cross rail slide 61 on which a rotary table 62 is rotatably mounted, and a pneumatic positioning fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com