Thermal spraying combined manufacturing process of lost foam cast ductile iron pipe fittings

A technology of ductile iron pipe and lost foam casting, which is applied in the field of foundry engineering, and can solve problems such as uneven coating, easy falling off of paint, and affecting the quality and quality of finished products, so as to avoid falling blocks, prevent sand sticking, and ensure quality and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

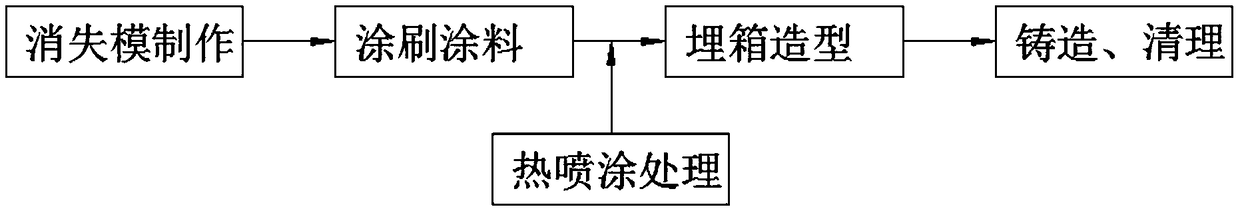

[0022] Embodiment one: if figure 1 As shown, the present invention provides a kind of manufacturing process of the lost foam casting ductile iron pipe fittings combined with thermal spraying, comprising the following steps:

[0023] a. Production of lost foam: make foam plastic into a real mold corresponding to the part structure and size of ductile iron pipe fittings;

[0024] b. Brushing paint: Assembling and drying the solid mold, coating the combined solid mold with anti-high temperature paint, and then drying the coating of the solid mold;

[0025] c. Thermal spraying treatment: thermal spraying treatment is carried out on the surface of the paint, the temperature of thermal spraying is 60-150°C, and the thickness of the thermal spraying material is not more than 1mm;

[0026] d. Buried box modeling: bury the solid mold in the sand box after the thermal spraying operation is completed;

[0027] e. Casting and cleaning: The metal liquid is poured under negative pressure ...

Embodiment 2

[0031] In order to make the effect of thermal spraying better, in step c in embodiment 1, the temperature of thermal spraying is 60-150°C.

Embodiment 3

[0033] In order to further optimize the flatness of the mold and ensure the quality of the finished product, the relationship between the size L model of the lost foam casting model in Example 1 and the size L cast iron pipe fitting of the nodular cast iron pipe fitting is:

[0034] L 模型 =L 铸铁管件 ×(1+1.5%)

[0035] Since the molten metal will shrink after cooling, by setting a shrinkage rate of 1.5%, it is ensured that the size of the ductile iron pipe fitting does not deviate in actual use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com