Preparation method and application of magnesium cobaltate spinel catalyst

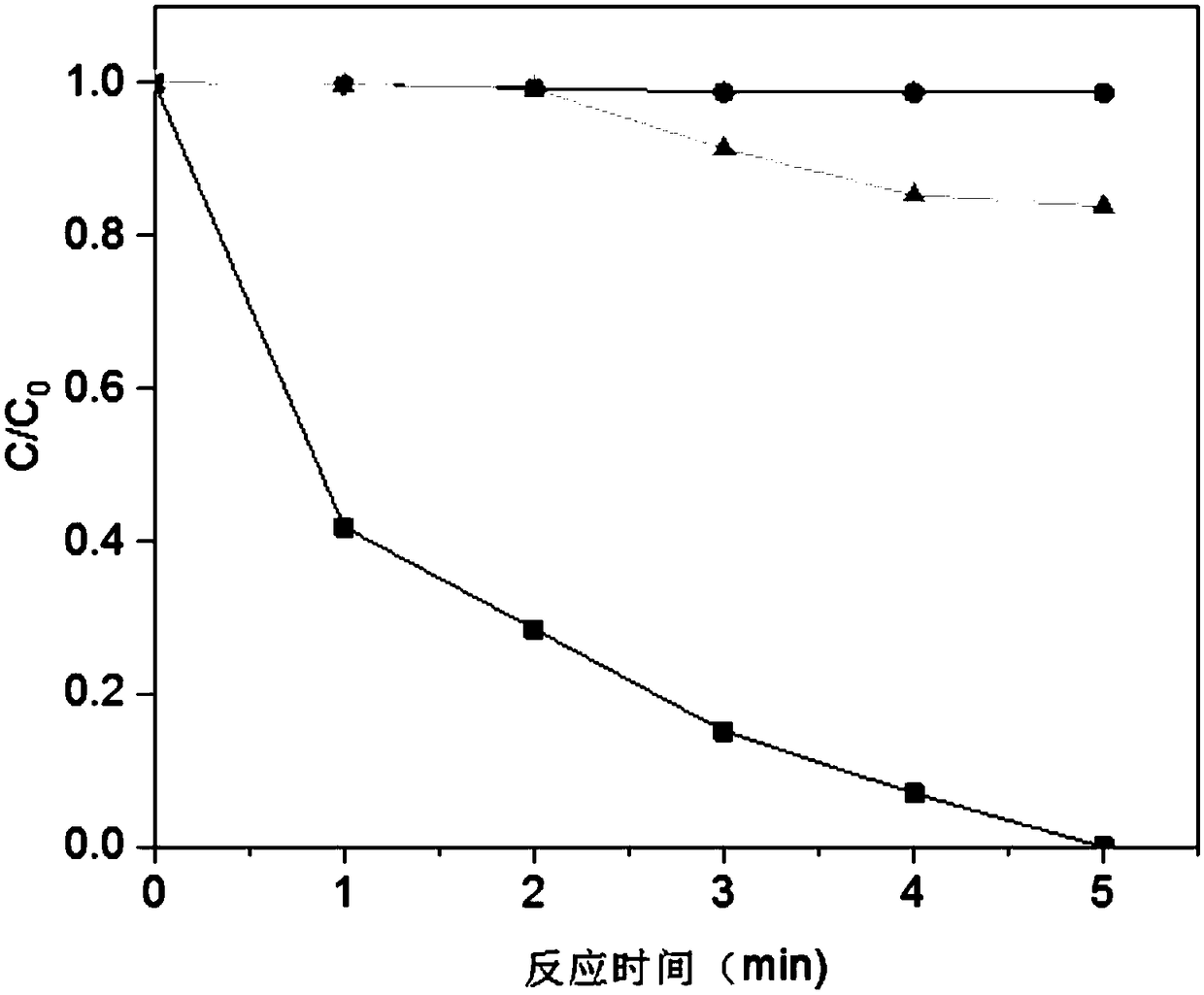

A magnesium cobaltate spinel and catalyst technology, which is applied in the field of water treatment, can solve the problems of slow degradation and incomplete degradation of bisphenol A, and achieve the effects of simple production method, complete degradation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the preparation method of a kind of magnesium cobaltate spinel catalyst of present embodiment, specifically carry out according to the following steps:

[0024] 1. Mix pure water with triethylene glycol, then add magnesium acetate and cobalt acetate, mix and stir evenly; then add urea, mix evenly, and obtain a mixed solution;

[0025] 2. Pour the mixed solution into the reaction kettle, then put it into an oven and heat it to a temperature of 160-200°C, and keep it for 5-10 hours to obtain the magnesium cobaltate precursor, then wash it with ultrapure water, and then use ethanol to wash it; then drying in an oven and grinding to obtain a prefabricated powder;

[0026] 3. Put the prefabricated powder obtained in step 2 into a muffle furnace for calcination, then cool and grind to obtain the magnesium cobaltate catalyst prepared by using spinel.

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the molar ratio of magnesium acetate and cobalt acetate in step one is (1~10):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the molar weight of urea in step one is 20% of the total molar weight of magnesium acetate and cobalt acetate. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com