Purification treatment method of volatile organic compounds (VOCs) waste gas

A treatment method and waste gas purification technology, which is applied in gas treatment, chemical instruments and methods, combustion methods, etc., can solve the problems of heavy burden on small and medium-sized enterprises, no application value of VOCs waste gas treatment, high cost of UV photolysis and plasma treatment combination machine, etc. problems, to achieve the effect of reducing rectification costs, reducing secondary pollution, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

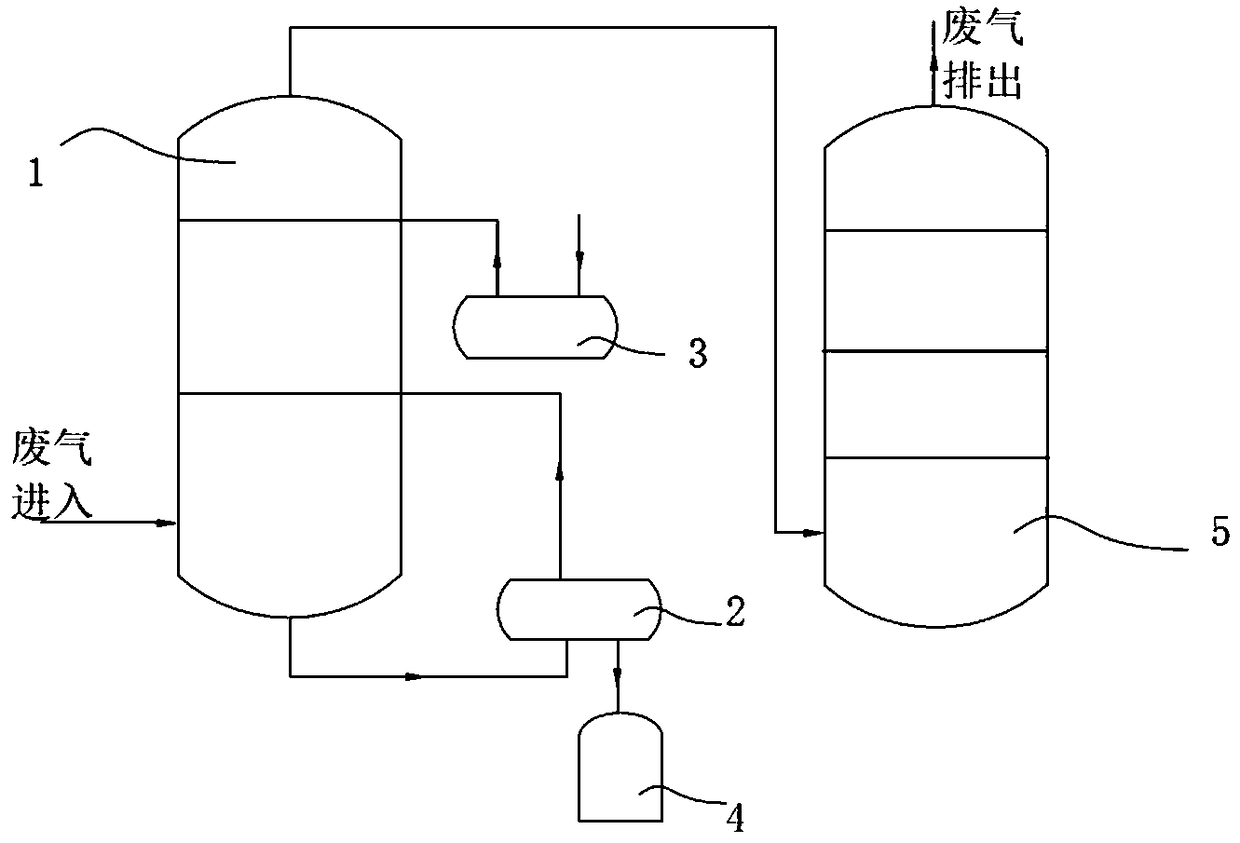

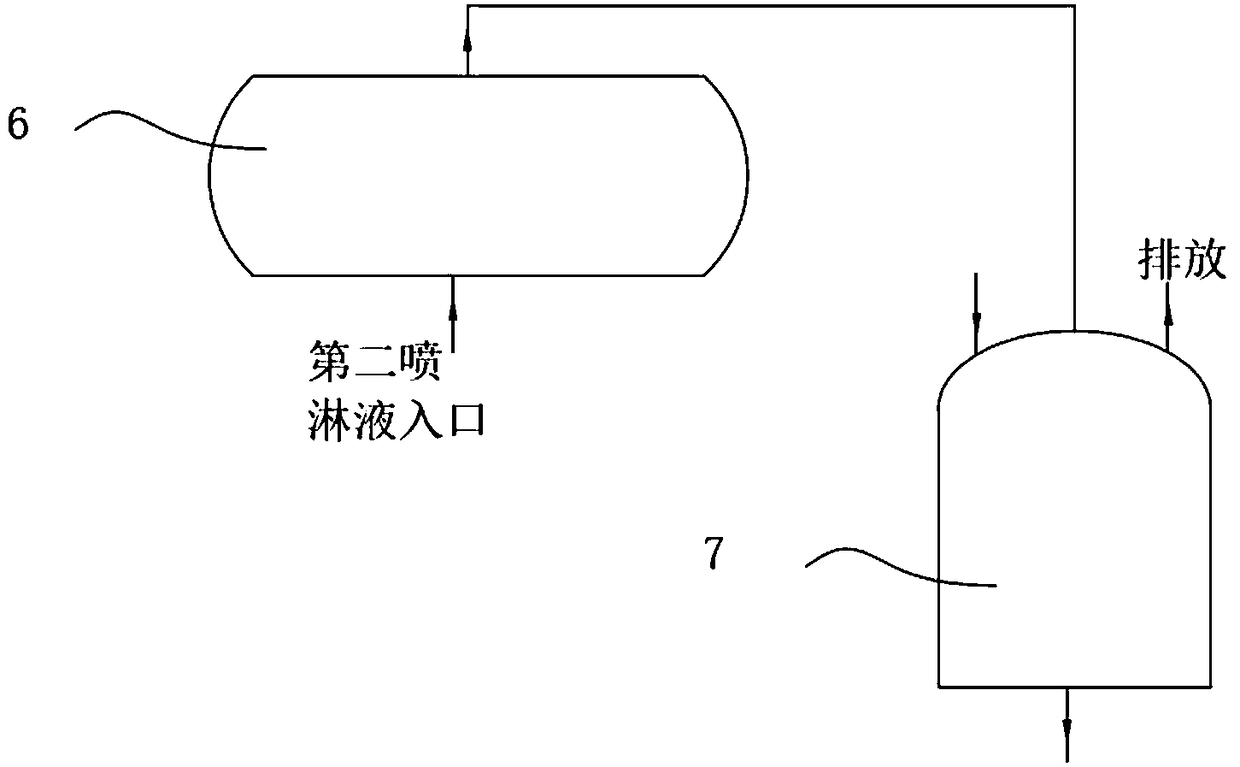

[0035] Example 1: A method for purifying and treating VOCs exhaust gas, refer to figure 1 with figure 2 , Including the following steps:

[0036] (1) Lye absorption

[0037] The VOCs exhaust gas enters the absorption tower 1 from the bottom of the absorption tower 1 for the first stage spray absorption and the second stage spray absorption in sequence. The middle and upper parts of the absorption tower 1 are sprayed from the first lye tank 2 respectively. The spray liquid and the second spray liquid from the second lye tank 3; the gas phase obtained after the secondary spray absorption is discharged from the pipeline set at the top of the absorption tower 1 to the adsorption tower 5; the first spray liquid The liquid-to-air flow ratio with VOCs exhaust gas, second spray liquid and VOCs exhaust gas is 1:500;

[0038] The second spray liquid in the second lye tank 3 is fresh lye from the external environment, and the fresh lye is saturated lime water; the liquid phase obtained after ...

Embodiment 2

[0049] Example 2: A method for purifying and treating VOCs exhaust gas. The difference from Example 1 is that the second non-woven bag is also filled with sodium alginate and sodium diatomite, activated carbon, calcium chloride powder, and nano-scale The mass ratio of polyaluminum chloride, polyacrylonitrile fiber, sodium alginate and sodium diatomite is 100:5:10:2:1:1;

[0050] The third non-woven bag is also filled with sodium alginate, sodium di alginate and sodium bicarbonate, activated carbon, calcium chloride powder, nano-grade polyaluminum chloride, polyacrylonitrile fiber, polyvinyl alcohol, ceramic powder, wheat The mass ratio of bran, sodium alginate, sodium diatomite and sodium bicarbonate is 100:5:10:2:1:2:2:1:1:3.

Embodiment 3

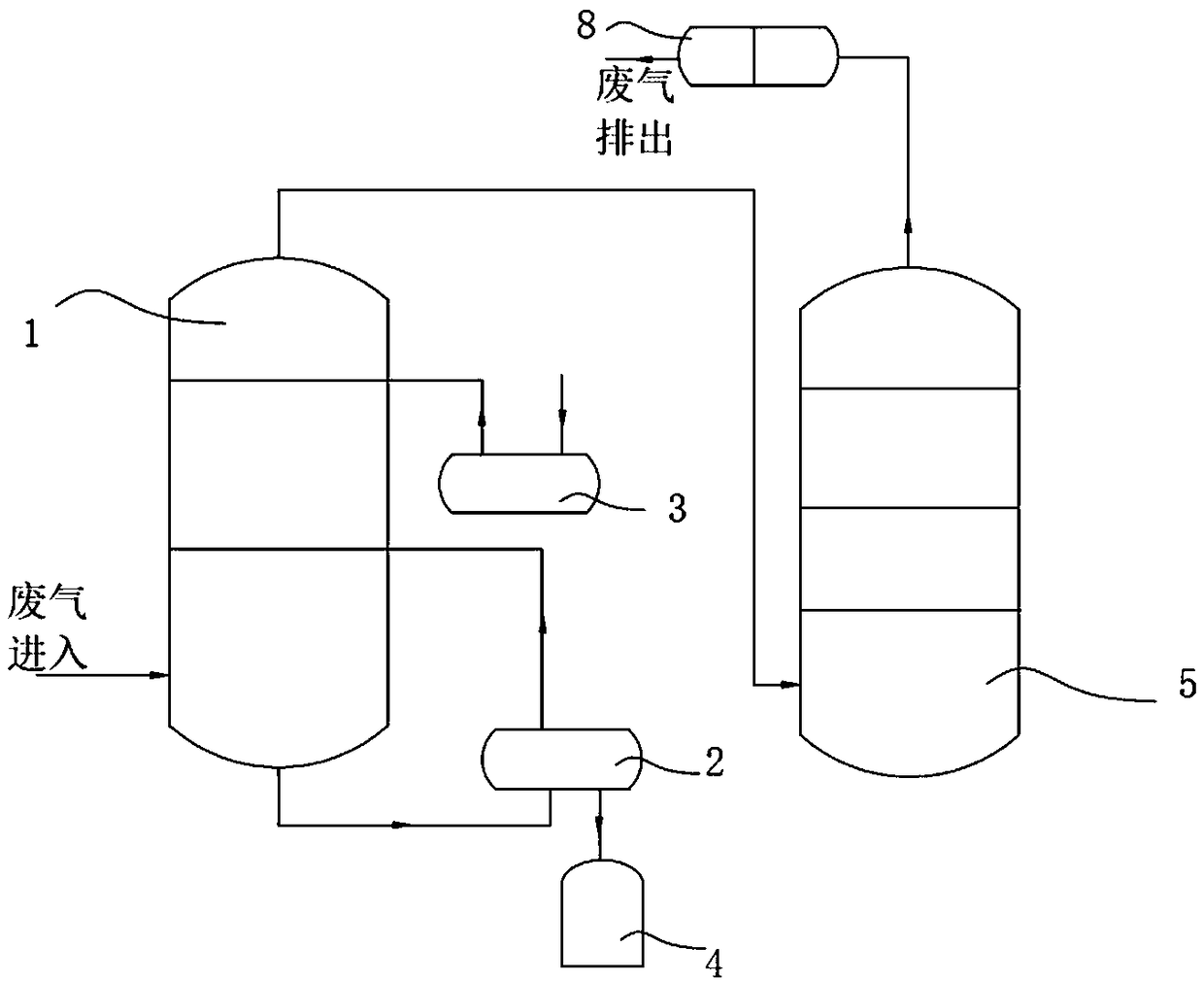

[0051] Embodiment 3: A VOCs exhaust gas purification treatment method, which is different from Embodiment 2 in that reference image 3 , The top of the adsorption tower 5 is connected with a re-adsorption tank 8 through a pipeline. The gas phase obtained after three-stage adsorption in the adsorption tower 5 enters the re-adsorption tank 8 from the inlet on the side of the re-adsorption tank 8 and is vertically arranged in the re-adsorption tank 8 The re-adsorption plate in the adsorption tank 8 absorbs, and then is discharged into the air from the outlet on the side far away from the inlet on the re-adsorption tank 8;

[0052] The resorption plate includes a resorption carrier plate adapted to the longitudinal section of the resorption tank and a coating coated on both sides of the resorption carrier plate. The thickness of the coating is 4mm. The coating includes 22wt% magnesium oxide and 32wt% Alumina and 46wt% magnesium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com