Internal resistance detection system and method based on weighting compensation degree factor

A detection method and battery voltage technology, applied in the direction of measuring resistance/reactance/impedance, measuring electricity, measuring devices, etc., can solve problems such as sudden increase in internal resistance measurement value, impossible suppression of interference and noise, and false value reporting by equipment. Achieve the effect of improving measurement accuracy, measuring speed and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below with reference to the drawings.

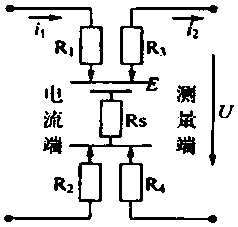

[0063] figure 1 It is the equivalent circuit diagram of the four-terminal measurement mode. R1, R2, R3 and R4 are the equivalent contact resistance; RS is the equivalent internal resistance of the battery; i1 is the excitation current; i2 is the measurement current.

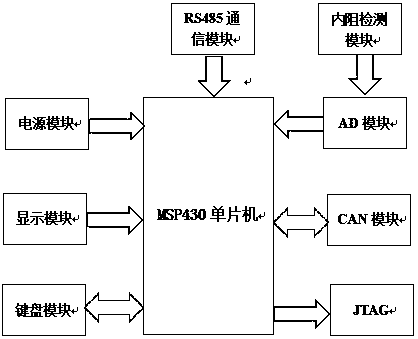

[0064] figure 2 Shown is the hardware structure diagram of the storage battery internal resistance detection system of the present invention. In the expansion and configuration design of the detection system, the present invention comprehensively considers both hardware and software, meets the requirements of low power consumption, improves reliability, anti-interference and combines the functions to be realized by the internal resistance measurement and control system of the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com