Asphalt mixture multi-sequence local loading high temperature performance test method

A technology for asphalt mixture and high-temperature performance, which is applied in the direction of analyzing materials, strength characteristics, and testing material strength by applying repeated force/pulsation force, which can solve unfavorable temperature, unfavorable road rutting prediction, and difficulty in applying thermal insulation coating thickness Control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Taking the test results of SMA-13 PG70-22 and PG82-22 modified asphalt mixtures at 62°C as an example, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods.

[0033] The inventive method comprises the following steps:

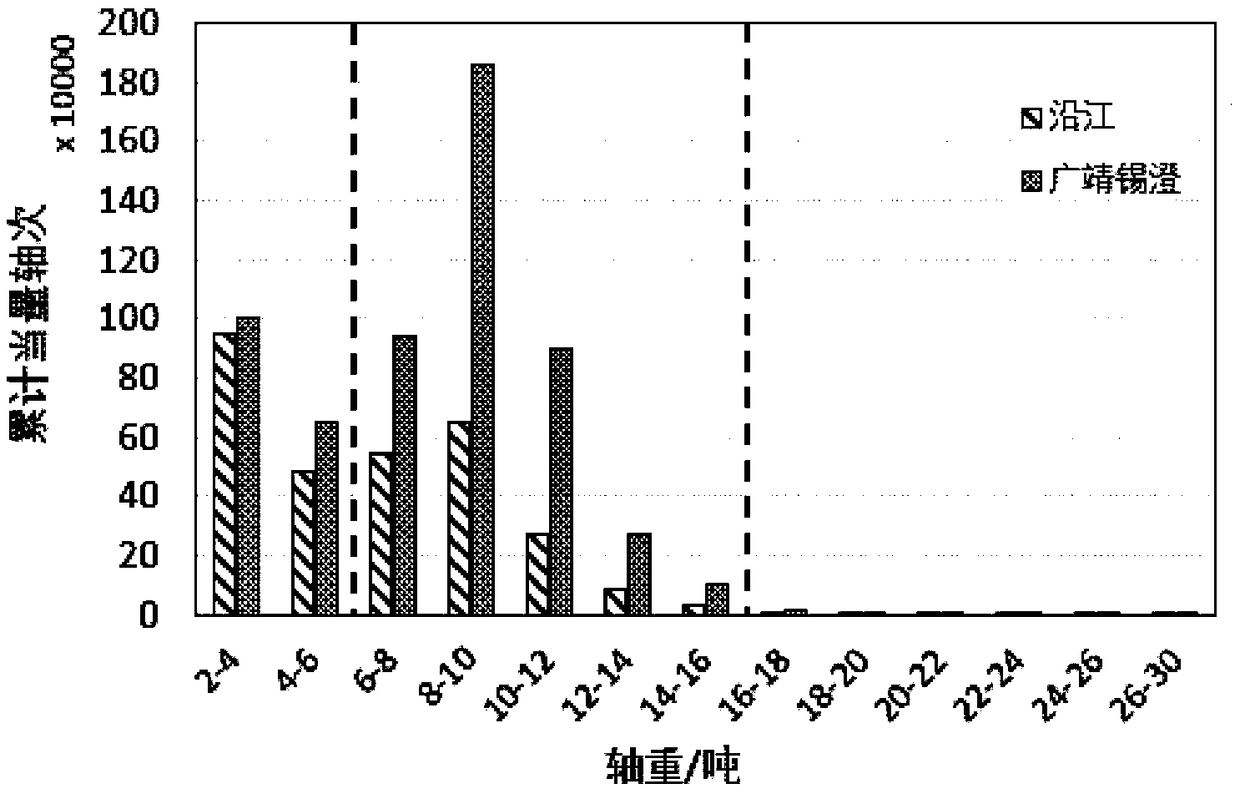

[0034] 1) According to the actual axle load spectrum of the expressway, determine the number of stress levels and the magnitude of the stress applied to the specimen in the test. Two expressways with different traffic levels in Jiangsu Province were selected, namely Yanjiang Expressway and Guangjing Xicheng Expressway, and the corresponding traffic levels were heavy traffic and extra heavy traffic. Inquire the axle load spectrum of the above roads in the last year in the road surface management system of Jiangsu Province, such as figure 1 shown.

[0035] Table 1 Distribution ratio of vehicles in different axle load intervals

[0036]

[0037] Depend on figure 1 It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com