High-temperature resisting leakproof type unfreezing acid for well drilling and preparation method thereof

A technology for high temperature resistance and acid removal, applied in the field of drilling, can solve the problems of poor leakage resistance and weak high temperature resistance, and achieve the effects of reducing acid fluid loss, shortening time, and eliminating stuck drill accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

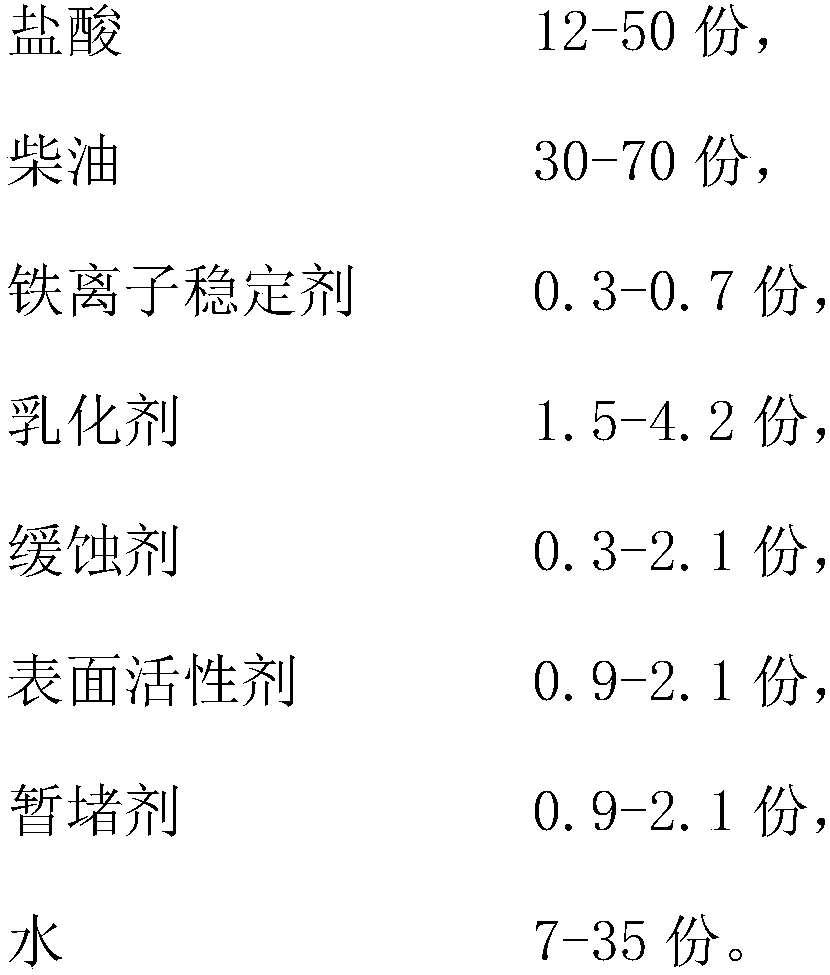

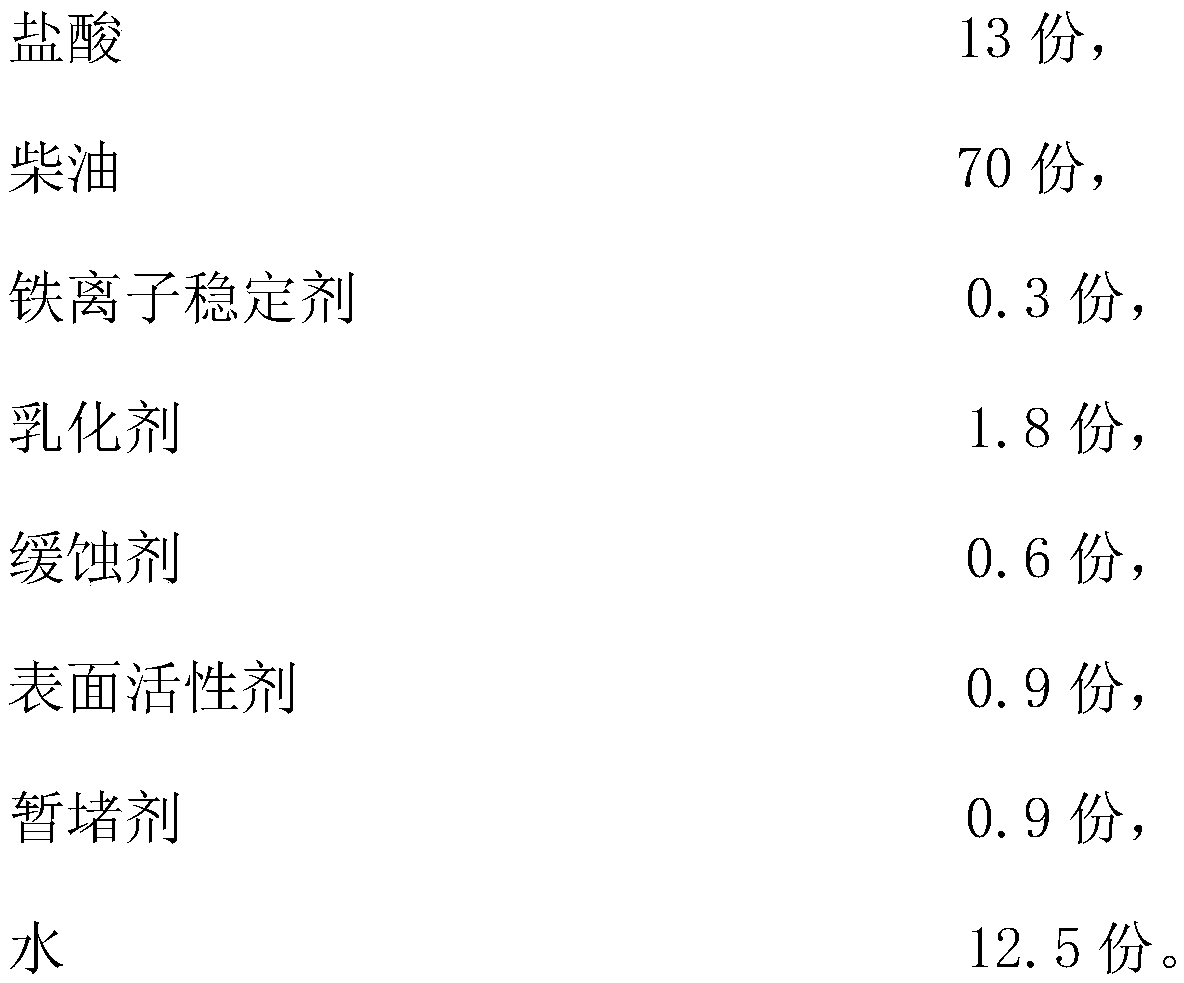

[0022] Embodiment 1, a kind of high temperature anti-leakage anti-leakage type carboxylic acid for well drilling, the components of the carboxylic acid and the parts by weight of each component are as follows:

[0023]

[0024] In this embodiment, the hydrochloric acid is industrial hydrochloric acid with a concentration of 31%, the diesel oil is 0# diesel oil, the emulsifier is industrial grade Swan 80, and the corrosion inhibitor is imidazoline type industrial corrosion inhibitor agent, the surfactant is a nonionic surfactant, the nonionic surfactant is polyoxyethylene octylphenol ether or polyoxyethylene nonylphenol ether, and the temporary blocking agent is organic sodium salt temporary Blocking agent.

[0025] In this embodiment, the preparation method of the anti-high temperature and anti-leakage type karyolytic acid for well drilling comprises the following steps: sequentially add 12.5 parts by weight of water, 0.6 parts by weight of corrosion inhibitor, and 13 parts...

Embodiment 2

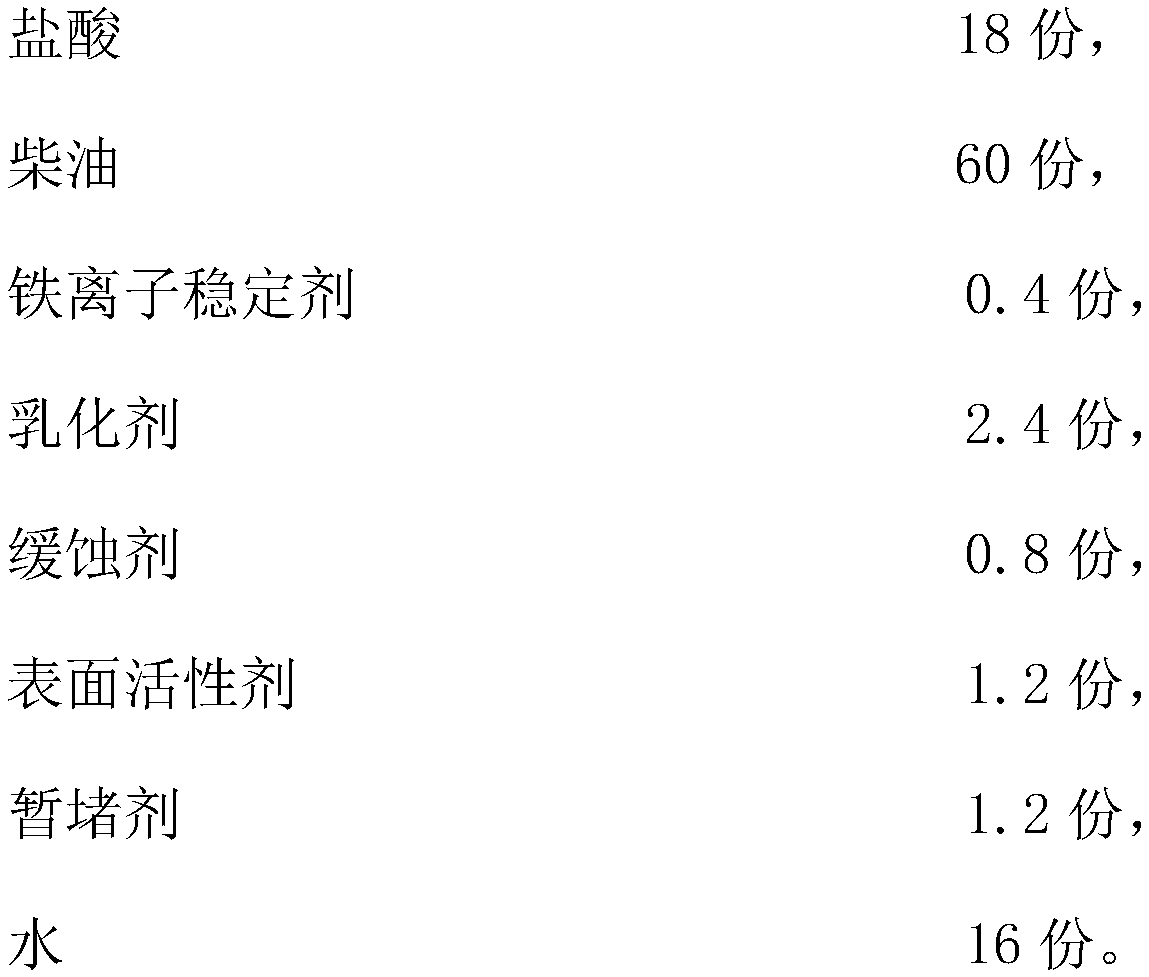

[0026] Embodiment 2, a kind of anti-high temperature and anti-leakage anti-leakage type carboxylic acid for well drilling, the components of the carboxylic acid and the parts by weight of each component are as follows:

[0027]

[0028] In this embodiment, the hydrochloric acid is industrial hydrochloric acid with a concentration of 31%, the diesel oil is 0# diesel oil, the emulsifier is industrial grade Swan 80, and the corrosion inhibitor is imidazoline type industrial corrosion inhibitor agent, the surfactant is a nonionic surfactant, the nonionic surfactant is polyoxyethylene octylphenol ether or polyoxyethylene nonylphenol ether, and the temporary blocking agent is organic sodium salt temporary Blocking agent.

[0029] In the present embodiment, the preparation method of the anti-high-temperature and anti-leakage type karboxic acid for drilling comprises the following steps: adding 16 parts by weight of water, 0.8 parts by weight of corrosion inhibitor, and 18 parts by...

Embodiment 3

[0030] Embodiment 3, a kind of anti-high temperature and anti-leakage type carboxylate for well drilling, the components of the carboxylate and the parts by weight of each component are as follows:

[0031]

[0032] In this embodiment, the hydrochloric acid is industrial hydrochloric acid with a concentration of 31%, the diesel oil is 0# diesel oil, the emulsifier is industrial grade Swan 80, and the corrosion inhibitor is imidazoline type industrial corrosion inhibitor agent, the surfactant is a nonionic surfactant, the nonionic surfactant is polyoxyethylene octylphenol ether or polyoxyethylene nonylphenol ether, and the temporary blocking agent is organic sodium salt temporary Blocking agent.

[0033] In the present embodiment, the preparation method of the anti-high temperature and anti-leakage type karyolysis acid for well drilling comprises the following steps: adding 20 parts by weight of water, 1.0 parts by weight of corrosion inhibitor, and 22.5 parts by weight of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com