Laminate film for molded decoration

A laminated film and molded body technology, applied in decorative art, decorative structure, special decorative structure, etc., can solve the problems of surface scars, reduced appearance decoration, reduced visual recognition, etc., to achieve excellent decoration, easy molding, The effect of excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

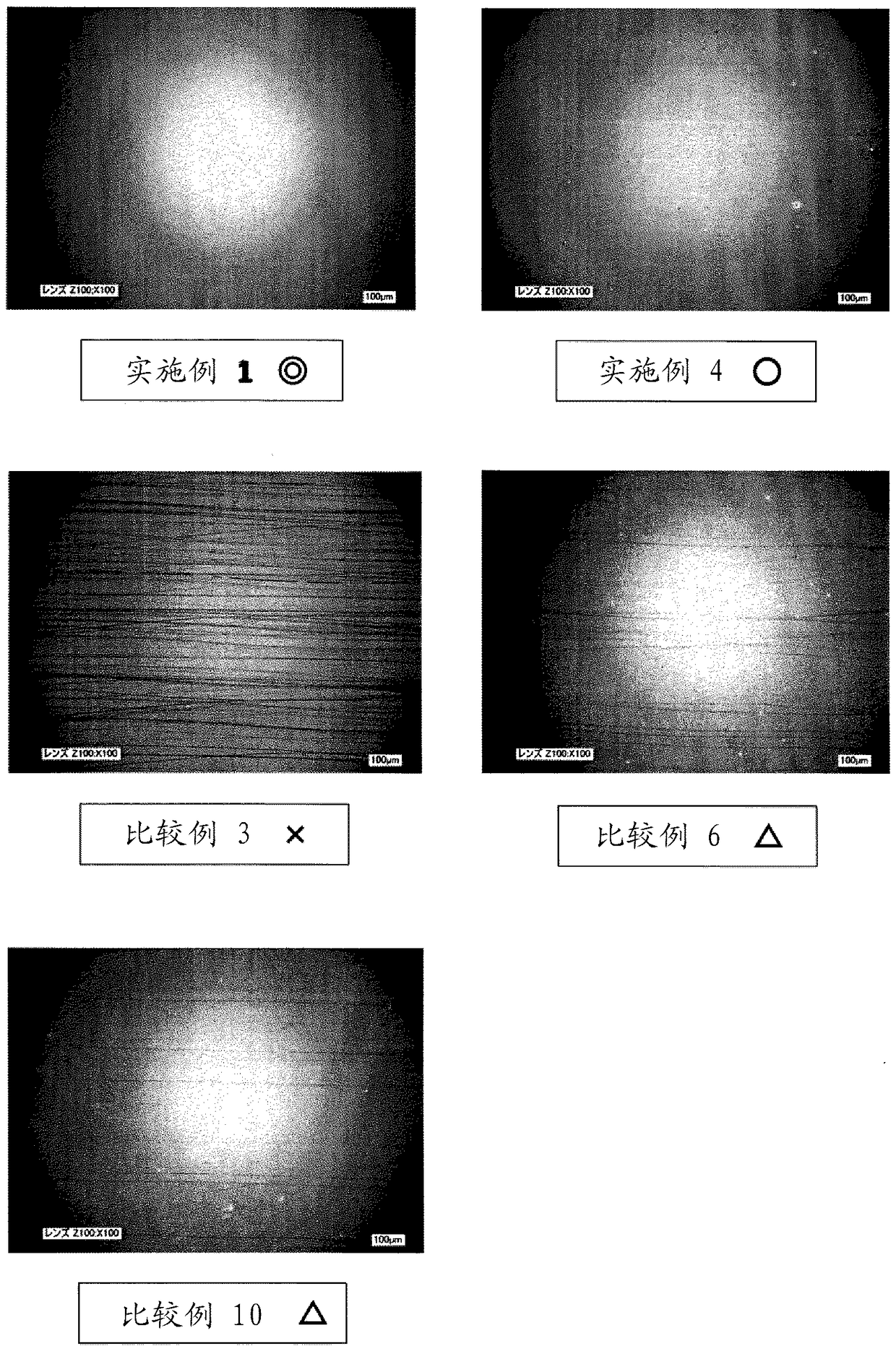

Examples

Embodiment

[0243] The present invention is further specifically illustrated by the following examples, but the present invention is not limited thereto. The "parts" and "%" in the examples are based on quality standards without particular limitation.

[0244] [Preparation of acrylic copolymer containing unsaturated double bond as the second component]

[0245] A mixture containing 171.6 g of isobornyl methacrylate, 2.6 g of methyl methacrylate, and 9.2 g of methacrylic acid was mixed. To 330.0 g of methyl isobutyl ketone heated to 110°C under a nitrogen atmosphere in a 1000 ml reaction vessel equipped with a stirring blade, a nitrogen introduction tube, a condenser, and a dropping funnel, the mixed solution and the mixture containing peroxy-2- A solution of 1.8 g of tert-butyl ethylhexanoate and 80.0 g of propylene glycol monomethyl ether was added dropwise at a constant rate over 3 hours, and then reacted at 110° C. for 30 minutes. Then, to 0.2 g of tert-butyl peroxy-2-ethylhexanoate, a so...

preparation example 1~11

[0247] The components described in the following Table 1 were mixed in the amounts described in the following Table 1 to prepare hard coating composition preparation examples 1 to 11.

[0248] In Hard Coating Composition Preparation Examples 9 and 10, an acrylate monomer or oligomer was used as the first component, and the unsaturated double bond-containing acrylic copolymer prepared as described above was used as the second component.

[0249] In Hard Coating Composition Preparation Example 9, the SP value of the first component was 12.1, and the SP value of the second component was 10.0.

[0250] In Hard Coating Composition Preparation Example 10, the SP value of the first component was 12.1, and the SP value of the second component was 10.0.

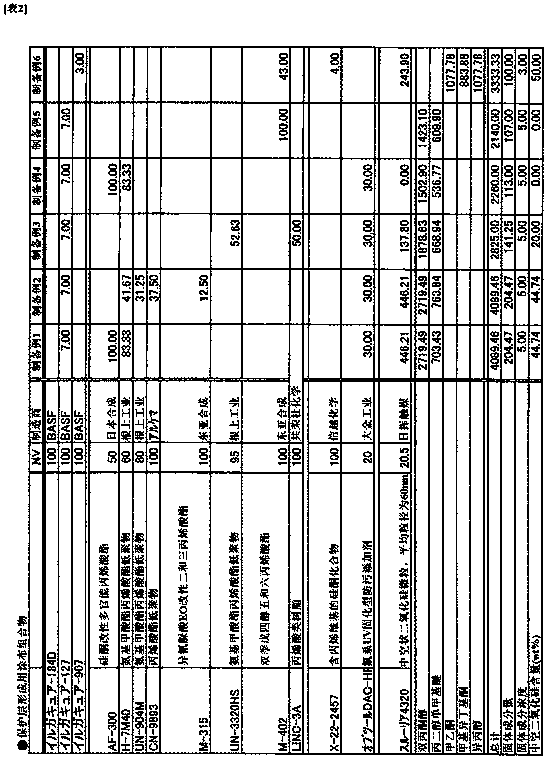

preparation example 1~6

[0252] The components described in Table 2 below were mixed in the amounts described in Table 2 below to prepare coating composition preparation examples 1 to 6 for forming a protective layer.

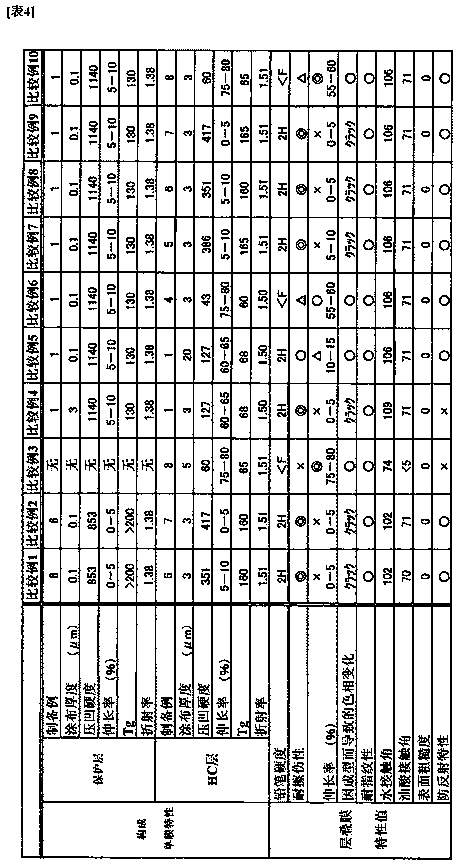

[0253] [Production conditions of laminated film for molded decoration]

[0254] On a transparent polymer substrate with a thickness of 300μm (Mitsubishi Gas Chemicals Yumolon DF02U, a film with an acrylic resin layer on the polycarbonate layer), it will be prepared at the specified ratio corresponding to each example and comparative example The hard coating composition is applied by a bar coater to achieve a predetermined film thickness, and dried at 80° C.×1 minute, and irradiated with ultraviolet rays at a cumulative light amount of 200 mJ to produce a hard coating layer.

[0255] On the surface of the prepared hard coat layer opposite to the transparent polymer substrate, the coating composition for forming the protective layer prepared in the prescribed ratio corresponding to the respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com