High-safety surge protection circuit and surge protection device

A surge protection and safety technology, applied in the field of power supply, can solve problems such as failure of protection circuit, failure of protection circuit of thermistor sheet 12, failure of varistor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

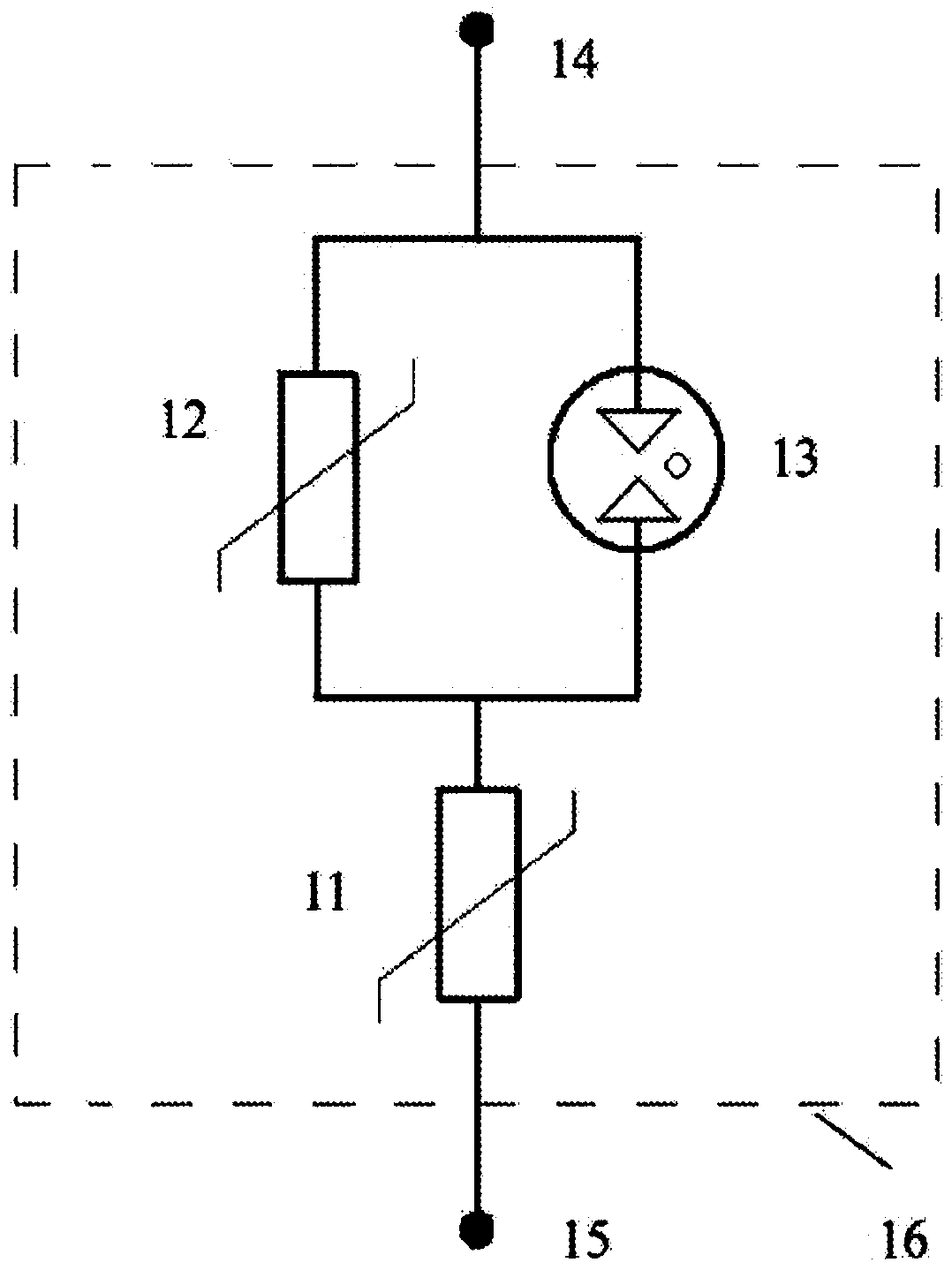

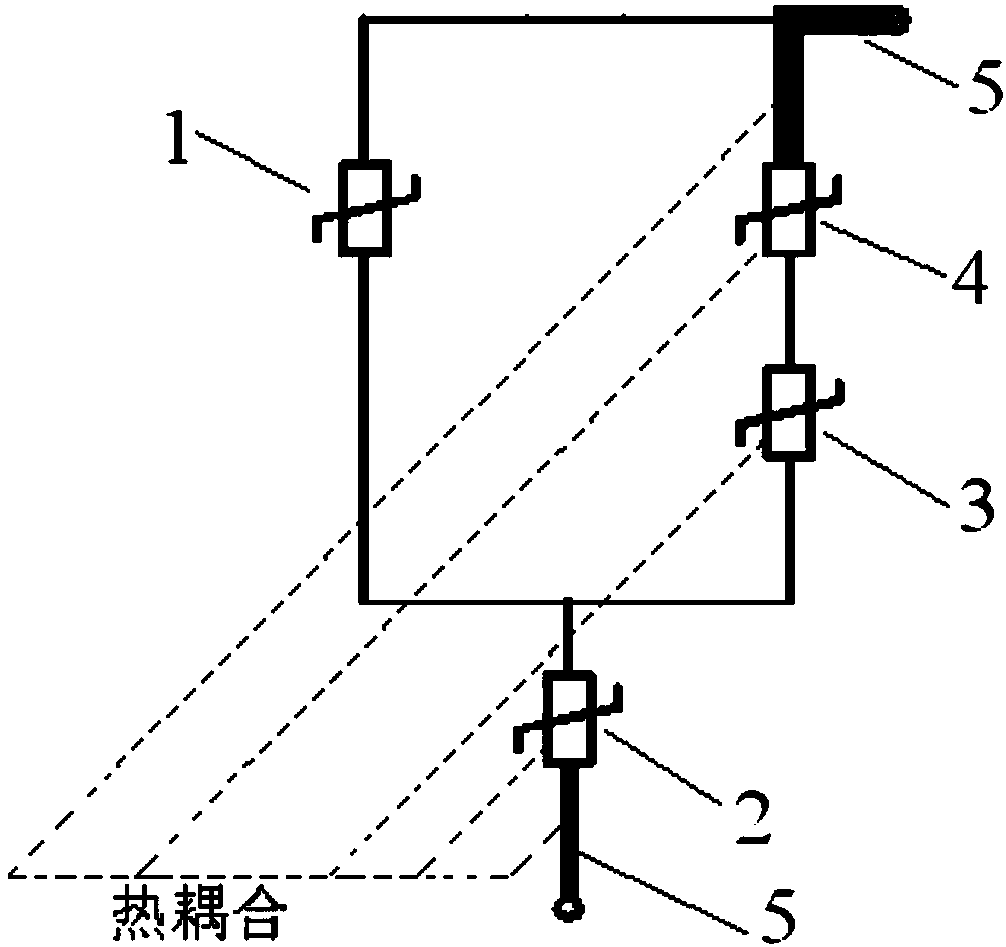

[0054] Such as image 3 As shown, a high-safety surge protection circuit includes a first varistor 1, a second varistor 2, a third varistor 3, a positive temperature coefficient thermistor 4 and a lead terminal 5 , the positive temperature coefficient thermistor sheet 4 is connected in parallel with the first varistor sheet 1 after being connected in series with the third varistor sheet 3, and the series-parallel branch is then connected with the second varistor sheet 2 in series to form a single-port combined circuit, wherein the performance of the first piezoresistor sheet 1 against surge impact is higher than that of the second piezoresistor sheet 2 .

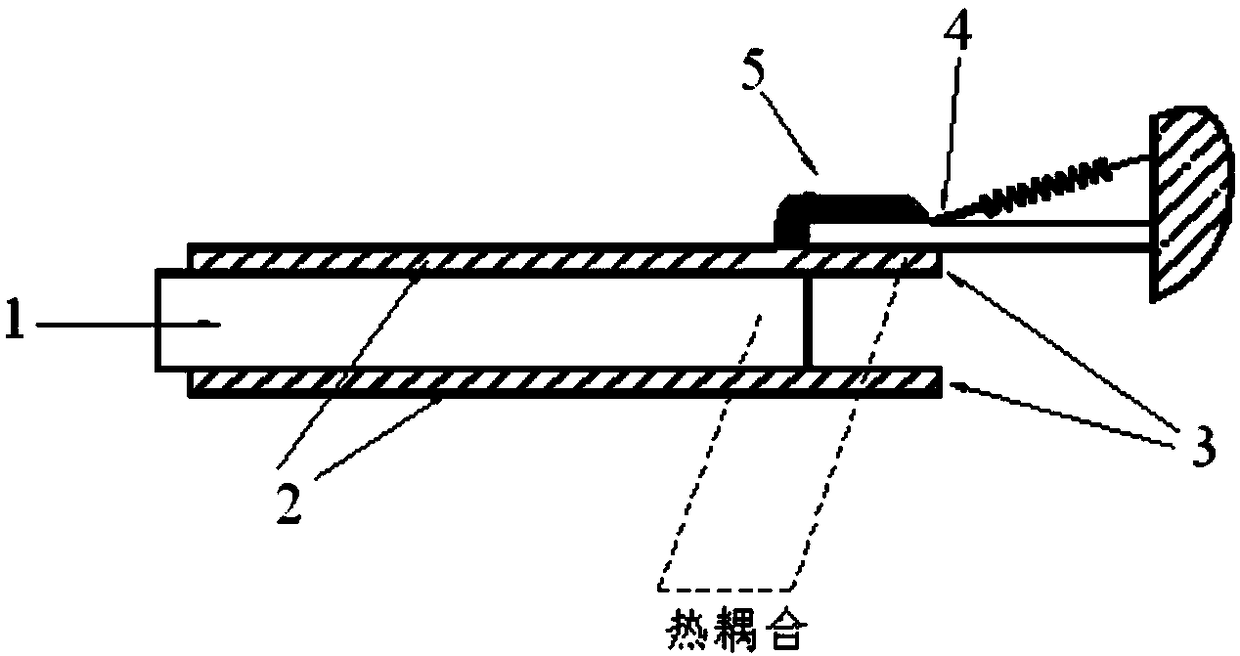

[0055] The two lead-out terminals 5 of the single-port combined circuit are both low thermal resistance heat-conducting terminals, the second varistor sheet 2 forms a thermal coupling with the third varistor sheet 3, and the third varistor sheet 3 forms a thermal coupling, and the third varistor sheet 3 forms a thermal coupl...

Embodiment 2

[0058] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that only one of the two lead-out terminals 5 of the single-port combined circuit is a low thermal resistance heat conduction terminal, and the second varistor sheet 2 and the third varistor The sensitive resistor sheet 3 forms a thermal coupling, and the third piezoresistor sheet 3 forms a thermal coupling with the positive temperature coefficient thermistor sheet 4, and the low thermal resistance heat conduction terminal and the second piezoresistor sheet 2 thermally coupled to each other.

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that only one of the two lead-out terminals 5 of the single-port combined circuit is a low thermal resistance heat conduction terminal, and the second varistor sheet 2 and the third varistor sheet 3 to form a thermal coupling, and the third varistor sheet 3 and the positive temperature coefficient thermistor sheet 4 form a thermal coupling. The low thermal resistance heat conduction terminal is thermally coupled with the positive temperature coefficient thermistor sheet 4 (such as Figure 5 shown), or the thermal coupling between the low thermal resistance heat conduction terminal and the third piezoresistor sheet 3 (such as Figure 6 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com