Lithium ion battery positive electrode material with low surface lithium ion content and preparation method thereof

A technology for lithium ion batteries and cathode materials, which is applied in the field of cathode materials for lithium ion batteries and their preparation, can solve the problems of time-consuming and laborious production efficiency, and achieves the effects of uniform dispersion, simple process flow and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

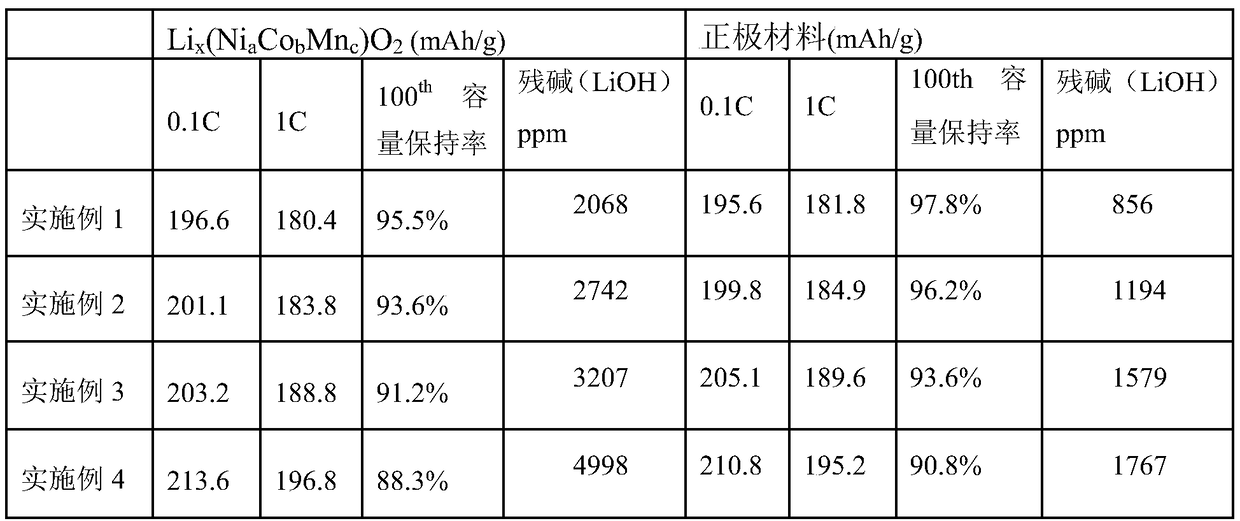

Embodiment 1

[0019] According to lithium hydroxide monohydrate and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio is 1.01, they are added in a high-speed mixer and mixed evenly, and then sintered at 790°C for 12h in a pure oxygen atmosphere to obtain an unmodified powder. Then nano ZrO 2 Ultrasonic mixing with 60 °C pure water to obtain a suspension with a mass concentration of 0.1%, and finally according to the nano-ZrO 2 The mass ratio of unmodified powder and unmodified powder is 2:1000, add unmodified powder, stir and mix, filter and evaporate to dryness, and sinter at 600°C for 2 hours to obtain a modified high-nickel cathode material.

Embodiment 2

[0021] According to lithium hydroxide monohydrate and Ni 0.82 co 0.12 mn 0.6 (OH) 2 The molar ratio is 1.03. After they are added into a high-speed mixer and mixed evenly, they are sintered at 770° C. for 15 hours under a pure oxygen atmosphere to obtain an unmodified powder. Nano ZrO 2 Mix with pure water at 60°C to obtain a suspension with a mass concentration of 0.2%, and finally follow the nano-ZrO 2 The mass ratio of unmodified powder and unmodified powder is 2.7:1000, add unmodified powder, stir and mix, filter and evaporate to dryness, and sinter at 500°C for 4 hours to obtain a modified high-nickel cathode material.

Embodiment 3

[0023] According to lithium hydroxide monohydrate and Ni 0.85 co 0.1 mn 0.5 (OH) 2 The molar ratio is 1.05. After they are added into a high-speed mixer and mixed evenly, they are sintered at 730° C. for 18 hours under a pure oxygen atmosphere to obtain an unmodified powder. Nano ZrO 2 Mix with pure water at 60°C to obtain a suspension with a mass concentration of 0.3%, and finally follow the nano-ZrO 2 The mass ratio of unmodified powder and unmodified powder is 4.05:1000, add unmodified powder, stir and mix, filter and evaporate to dryness, and sinter at 400°C for 6 hours to obtain a modified high-nickel cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com