Mesoporous lithium aluminum silicate coated doped single crystal ternary positive electrode material and preparation method thereof

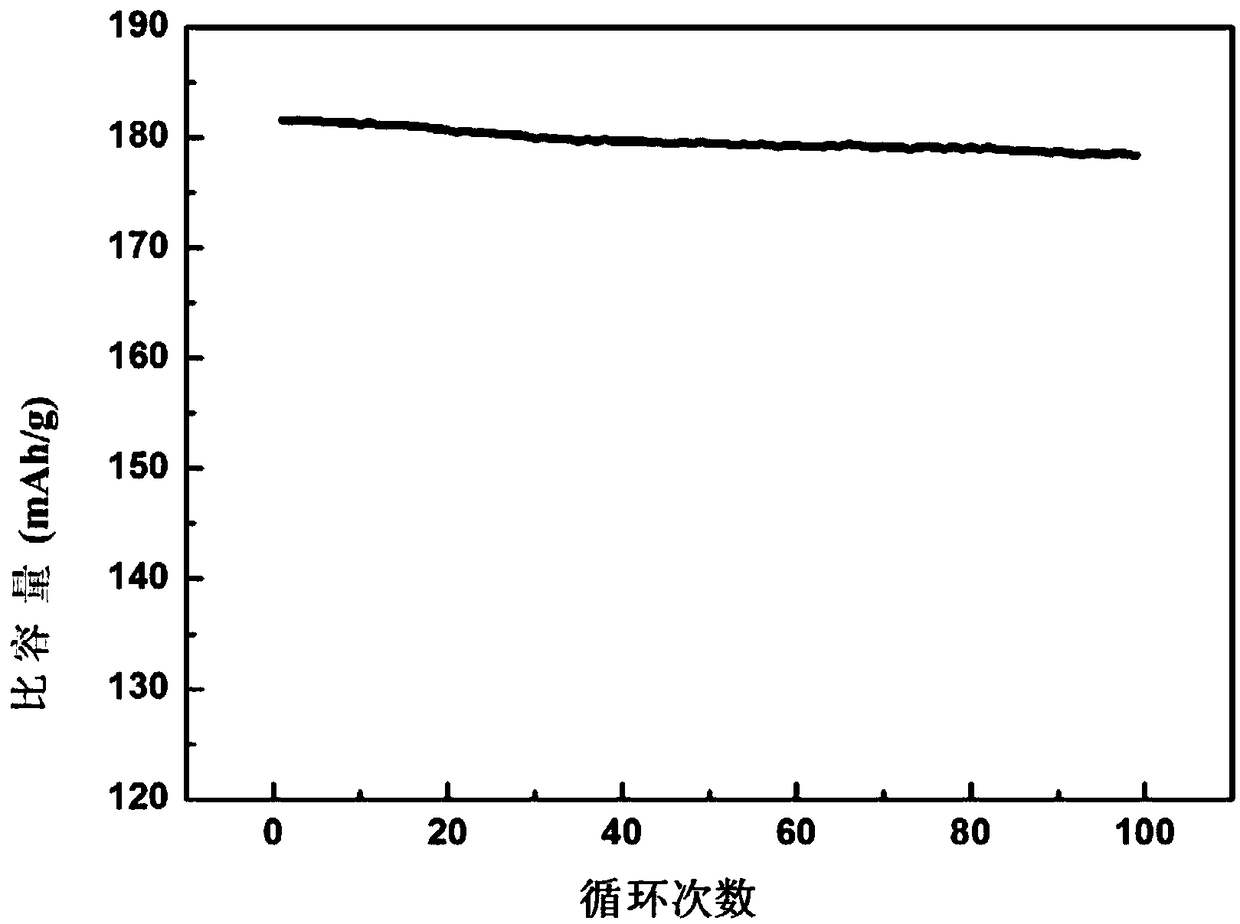

A technology of lithium aluminum silicate and positive electrode material is applied in the field of doped single crystal ternary positive electrode material and its preparation, doped single crystal nickel cobalt lithium manganate ternary material z) and its preparation field, which can solve the problem of easy problems. Damage the surface of the material, aggravate the surface of the material, shorten the cycle life of the material, etc., and achieve the effects of good high-voltage cycle stability, high initial specific capacity, and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh nickel sulfate, cobalt sulfate, manganese sulfate, and aluminum sulfate according to the stoichiometric ratio of Ni, Co, Mn, and Al 0.55:0.20:0.23:0.02 and dissolve them in deionized water to make a total concentration of metal cations of 2mol / L mixed solution, and stirred to make it fully mixed to obtain a mixed salt solution, while adding 3mol / L sodium hydroxide solution and 5mol / L ammonia solution to the mixed salt solution to make the pH value of the mixed salt solution 10, aging reaction After 12 hours, the product was separated by centrifugal filtration and washed to obtain a reaction precipitate. Finally, the washed product was dried at 105-120°C to obtain 0.55 co 0.2 mn 0.23 al 0.02 (OH) 2 Al-doped precursors.

[0045] (2) Weigh 10Kg of Ni respectively 0.55 co 0.2 mn 0.23 al 0.02 (OH) 2 and 4.30Kg of Li 2 CO 3 Add it into a high-efficiency mixer, and mix it efficiently for 20 minutes to obtain a uniform mixture; then put the mixture in an at...

Embodiment 2

[0051] (1) Weigh nickel sulfate, cobalt sulfate, manganese sulfate, and zirconium sulfate according to the stoichiometric ratio of Ni, Co, Mn, and Zr 0.55:0.15:0.29:0.01 and dissolve them in deionized water to make a total concentration of metal cations of 2mol / L mixed solution, and stirred to make it fully mixed to obtain a mixed salt solution, while adding 3mol / L sodium hydroxide solution and 5mol / L ammonia solution to the mixed salt solution to make the pH value of the mixed salt solution 10, aging reaction After 12 hours, the product was separated by centrifugal filtration and washed to obtain a reaction precipitate. Finally, the washed product was dried at 105-120°C to obtain 0.55 co 0.15 mn 0.29 Zr 0.01 (OH) 2 Zr-doped precursors.

[0052] (2) Weigh 10Kg of Ni respectively 0.55 co 0.15 mn 0.29 Zr 0.01 (OH) 2 and 4.25Kg of LiOH were added to a high-efficiency mixer, and mixed efficiently for 18 minutes to obtain a uniform mixture; then the mixture was placed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com