Electronic device with low stress and high overload resistance and packaging method of electronic device

An electronic device and packaging method technology, applied in the packaging field of electronic devices, can solve the problems of large contact area, low stress on electronic chips, and no coverage by any objects, and achieves the effect of low packaging stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

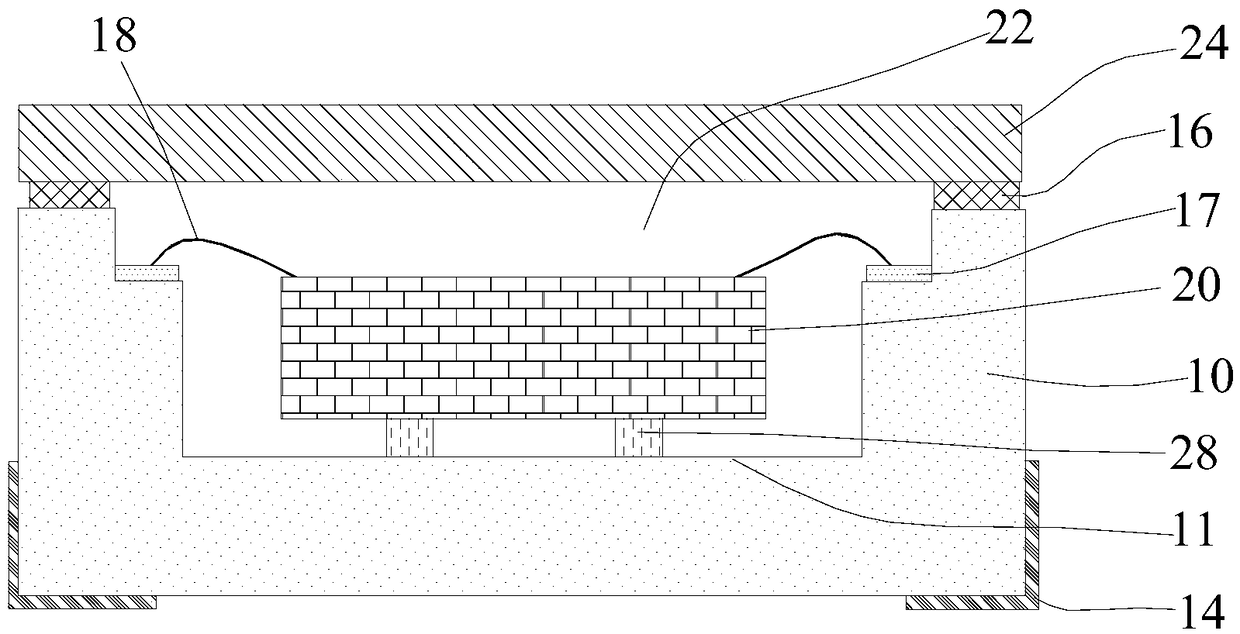

Embodiment 1

[0040] Electronics with low stress and high overload resistance at the same time, such as Figure 10 As shown, it includes a package shell 10, a package cover plate 24 and an electronic chip 20. The package cover plate 24 is combined with the package tube shell 10 by solder 16 to form a sealed cavity 22 for protecting the electronic chip 20. The package cover plate 24 The material can be plastic, ceramics, Kovar, glass, germanium, silicon, etc., and the material of the package package 10 can be plastic, ceramics, etc. On the inner surface 24a of the package cover plate 24, a patterned upper protective soft rubber 33 is made. The soft glue 33 can buffer mechanical force, protect the electronic chip 20 from colliding with the packaging cover plate 24, and because the upper protective soft glue 33 is very soft, even if the electronic chip 20 collides with it, it will not cause damage. The figure of the upper protective soft glue 33 is Square, rectangular, circular, etc., there i...

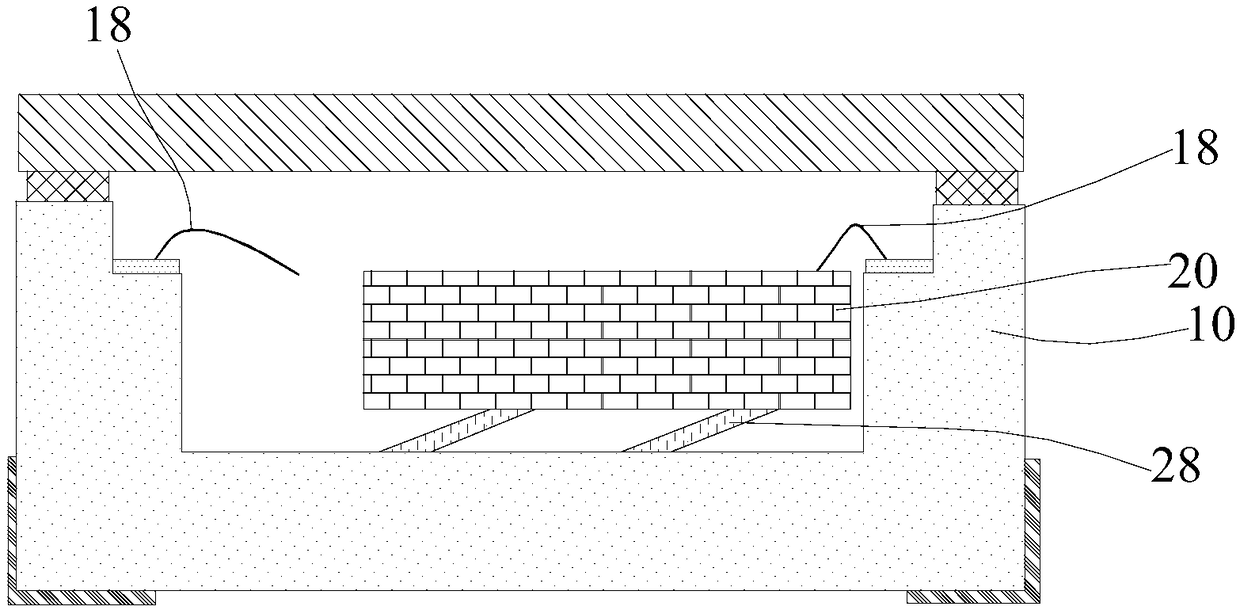

Embodiment 2

[0050] Electronics with low stress and high overload resistance at the same time, such as Figure 11 As shown, it includes a package shell 10, a package cover plate 24 and an electronic chip 20. The package cover plate 24 is combined with the package tube shell 10 by solder 16 to form a sealed cavity 22 for protecting the electronic chip 20. The package cover plate 24 The material can be plastic, ceramics, Kovar, glass, germanium, silicon, etc., and the material of the package package 10 can be plastic, ceramics, etc. On the inner surface 24a of the package cover 24, a patterned upper protective soft rubber 33 is made. The hardness of the material is relatively low, such as silicone or epoxy glue with a Shore hardness of 20-100. The soft glue 33 can buffer mechanical force, protect the electronic chip 20 from colliding with the packaging cover plate 24, and because the upper protective soft glue 33 is very soft, even if the electronic chip 20 collides with it, it will not caus...

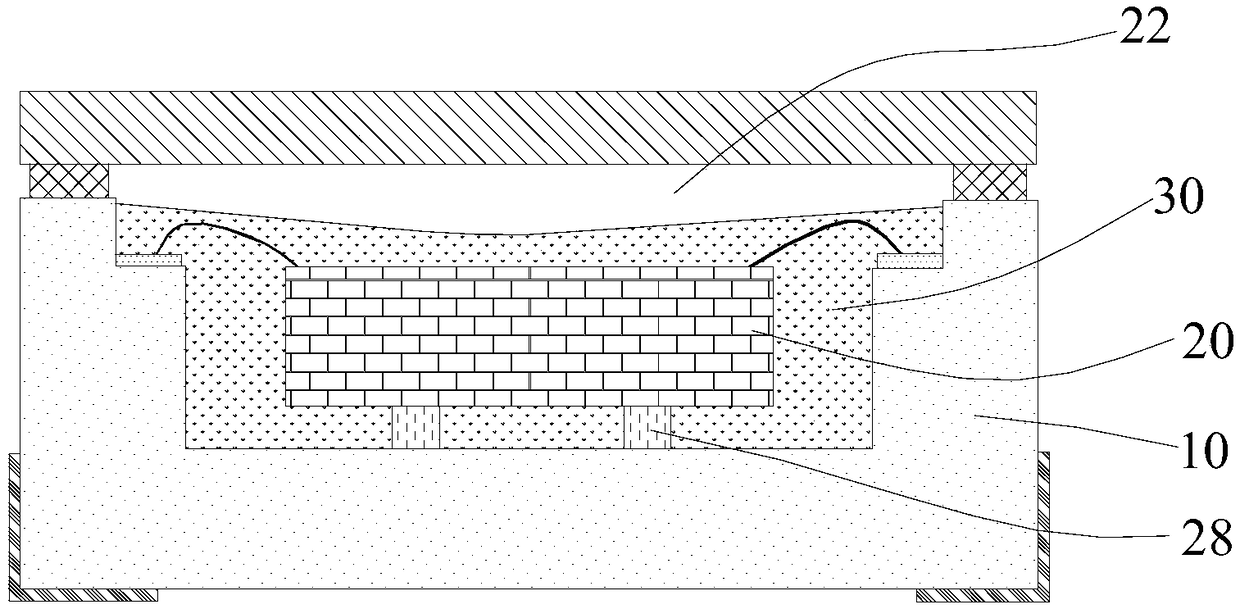

Embodiment 3

[0053] Electronics with low stress and high overload resistance at the same time, such as Figure 12As shown, it includes a package shell 10, a package cover plate 24 and an electronic chip 20. The package cover plate 24 is combined with the package tube shell 10 by solder 16 to form a sealed cavity 22 for protecting the electronic chip 20. The package cover plate 24 The material can be plastic, ceramics, Kovar, glass, germanium, silicon, etc., and the material of the package package 10 can be plastic, ceramics, etc. On the inner surface 24a of the package cover 24, a patterned upper protective soft rubber 33 is made. The hardness of the material is relatively low, such as silicone or epoxy glue with a Shore hardness of 20-100. The soft glue 33 can buffer mechanical force, protect the electronic chip 20 from colliding with the packaging cover plate 24, and because the upper protective soft glue 33 is very soft, even if the electronic chip 20 collides with it, it will not cause...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com