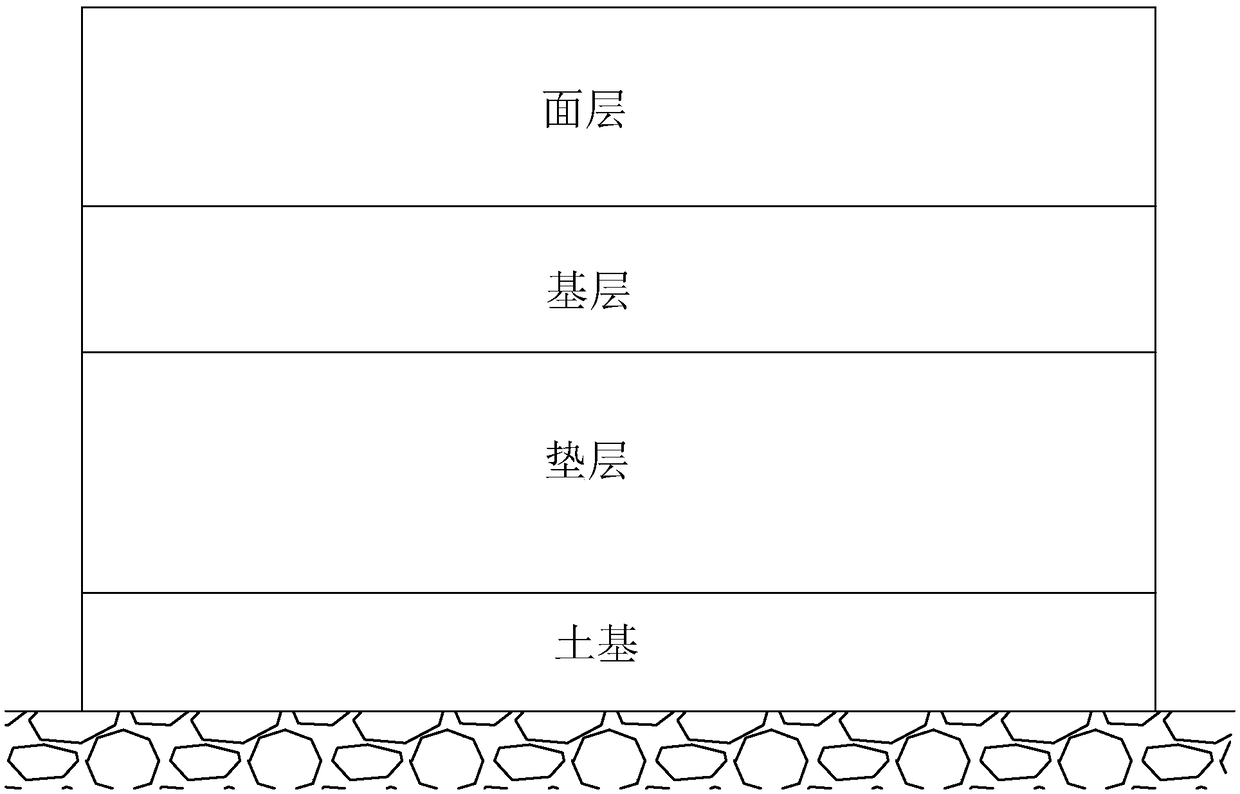

Construction process of airport runway

A construction technology, airport runway technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of asphalt mixture performance degradation, etc., to achieve the effect of reducing cracks, increasing compactness, and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

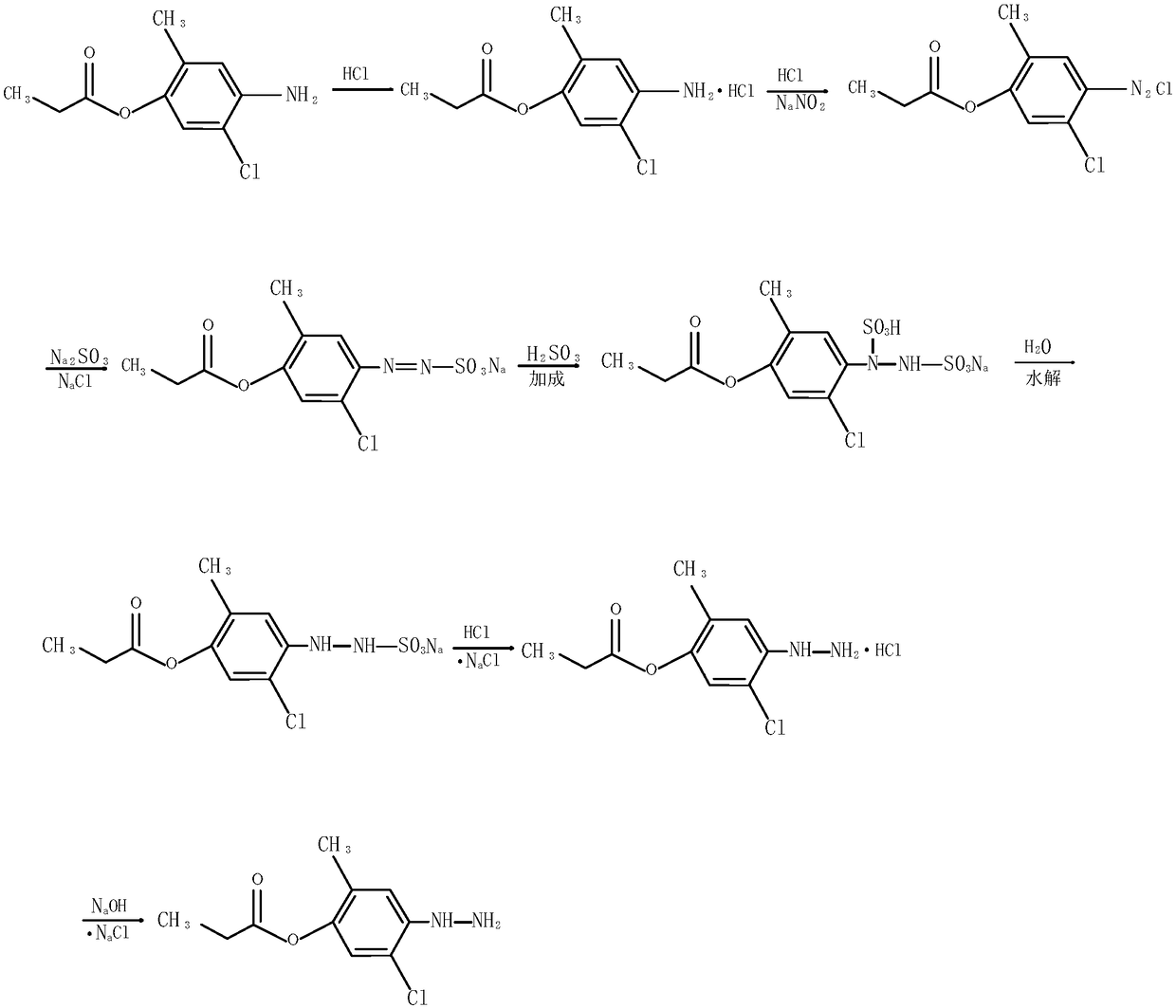

Method used

Image

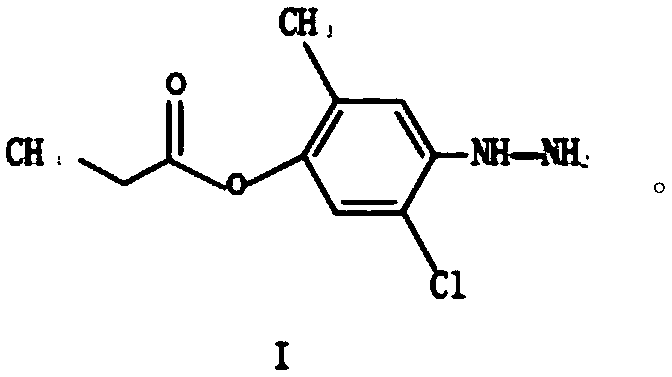

Examples

preparation example 1

[0033] Heat 100kg of base asphalt to 170°C, add 2kg of SBS resin, swell at 170°C for 0.5 hours, then heat up to 175°C and grind with a colloid mill, then add 1kg of rubber softening oil; control the temperature and stir at 180°C for 2 hours to reduce After the temperature reaches 170°C, add 0.005kg of stabilizer and stir for 1 hour.

preparation example 2

[0035] Heat 100kg of base asphalt to 173°C, add 3kg of SBS resin, swell at 173°C for 1 hour, then heat up to 178°C and use a colloid mill to grind, then add 3kg of rubber softening oil; control the temperature at 183°C and stir for 2.5 hours to reduce After the temperature reached 173°C, 0.01kg of stabilizer was added and stirred for 1.5h.

preparation example 3

[0037] Heat 100kg of base asphalt to 175°C, add 5kg of SBS resin, swell at 175°C for 1 hour, then heat up to 180°C and use a colloid mill to grind, then add 6kg of rubber softening oil; control the temperature and stir at 85°C for 3 hours, reduce After the temperature reaches 175°C, add 0.02kg of stabilizer and stir for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com