One-step desizing pretreatment process for modified fiber fabric

A modified fiber and pre-treatment technology, applied in textile material treatment, solvent treatment, dry cleaning fiber products, etc., can solve the problems of incomplete singeing and poor degreasing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

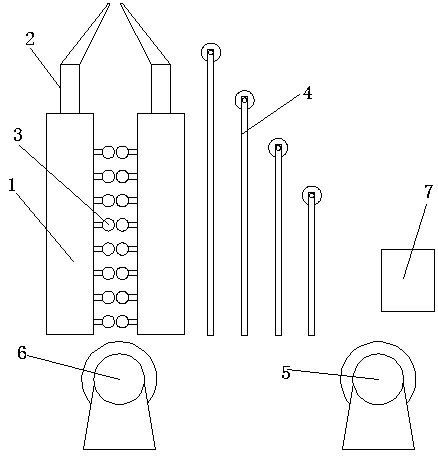

Image

Examples

Embodiment

[0027] Embodiment: one-step desizing pre-treatment process for modified fiber fabrics, comprising the following steps:

[0028] (1) Acceptance and inspection of raw materials: The physical and chemical properties, strength, and flame-retardant appearance of the materials are mainly inspected. The physical and chemical properties, strength, and flame-retardant properties of the materials are inspected by corresponding inspection equipment. For the appearance of the materials, the materials need to be placed In a closed room, set up lights in the room, and check whether there are burrs by illuminating the surface of the bobbin through the lights. The raw materials that pass the inspection are stored in the specified warehouse according to the principle of first-in-first-out. The warehouse must be protected from light, moisture and dust;

[0029] (2) Raw material pretreatment: including wire drawing, unwinding and twisting. Raw materials are formed into warp yarns and weft yarns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com