Efficient short-process printing and dyeing process of modified fiber fabric

A technology of modified fiber and printing and dyeing process, which is applied in the field of high-efficiency short-process printing and dyeing process of modified fiber fabrics. It can solve the problems of incomplete singeing, low dyeing quality, and poor oil removal effect, and achieve good dyeing effect and color fastness High, improve the effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: The high-efficiency short-flow printing and dyeing process of modified fiber fabrics includes the following steps:

[0031] (1) Raw fabric preparation: including raw fabric inspection, fabric turning and seam;

[0032] (2) Singeing: singeing the surface of the fabric in the singeing equipment with high temperature flame;

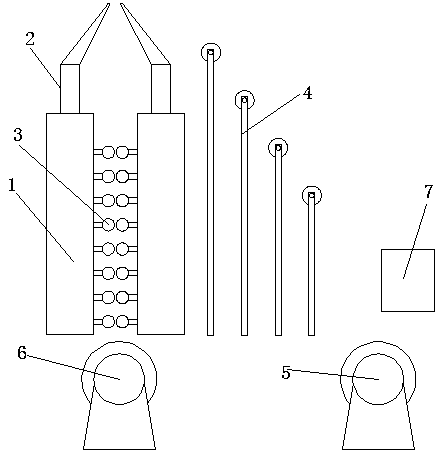

[0033] Refer to attached figure 1 As shown, the singeing equipment includes a high-temperature metal singeing device, a cloth receiver 5, a cloth release device 6 and a set of support rollers. In the process of singeing the fabric, the set of support rollers is set before and after the singeing of the fabric. During the singeing process, the heating device 1 will burn the metal to red heat, and the two The gap between the metal knives 2 is the fast singeing channel of the fabric; the metal knives 2 are arranged obliquely, and the ends of the metal knives 2 are processed into arc surfaces to prevent the tip from facing the fabric from bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com