Hub surface pretreatment process

A treatment process and a technology for the surface of the wheel hub, which is applied in the direction of metal material coating process, etc., can solve the problems of short service life, easy peeling off of the coating layer, and increase the microscopic roughness of the wheel hub surface, so as to enhance corrosion resistance and increase microscopic roughness , Improve the effect of surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

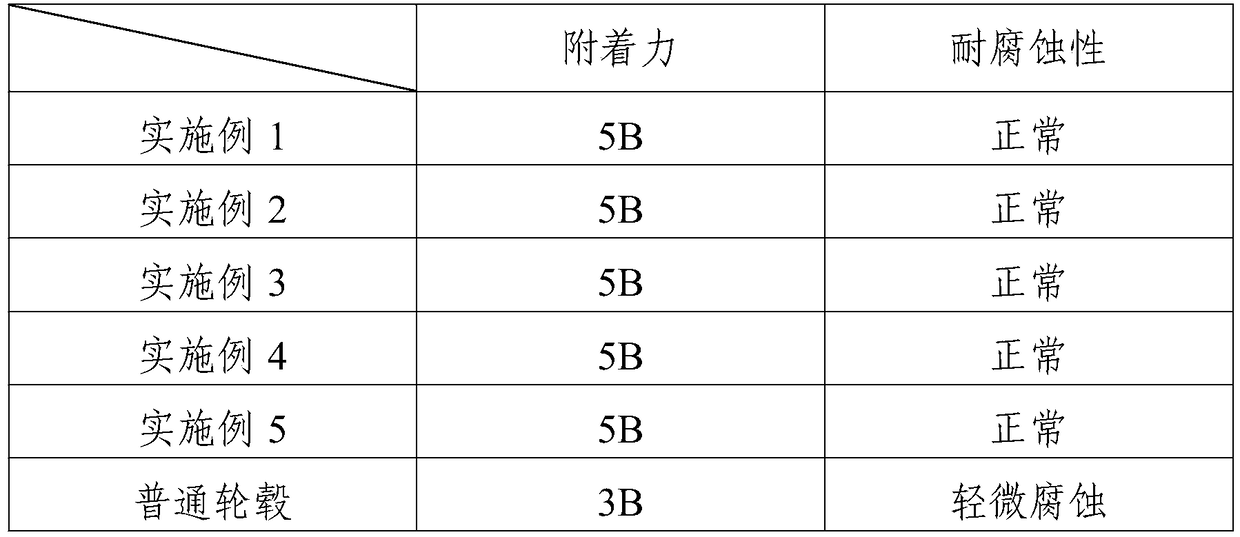

Examples

Embodiment 1

[0021] A wheel hub surface pretreatment process, comprising the following steps:

[0022] (1) Hot water washing: put the hub in a washing tank, soak the hub in hot water at a temperature of 60°C for 15 minutes, and then use a brush to wipe off the aluminum chips and dust on the surface of the hub;

[0023] (2) Degreasing treatment: the wheel hub is placed in a washing tank, the wheel hub is soaked in the mixed solution of water, concentrated cleaning agent and surfactant, 2wt% potassium hydroxide solution, and ultrasonic treatment is carried out for 15min. The ultrasonic power is 500W. After the ultrasonic is over, take out the hub, and then spray the surface of the hub with the mixed liquid, repeat the spraying 2 to 3 times, and rinse the surface of the hub with hot water at a temperature of 50°C after the spraying is completed. , the flushing process is carried out according to the spray pressure of 0.1MPa and the flushing time of 1.2min, and the flushing is repeated several...

Embodiment 2

[0028] A wheel hub surface pretreatment process, comprising the following steps:

[0029] (1) Hot water washing: put the hub in a washing tank, soak the hub in hot water at a temperature of 65°C for 20 minutes, and then use a brush to wipe off the aluminum chips and dust on the surface of the hub;

[0030] (2) Degreasing treatment: place the wheel hub in a washing tank, soak the wheel hub in a mixture of water, concentrated cleaning agent, surfactant, and 1 wt% potassium hydroxide solution, and perform ultrasonic treatment for 20 min. The ultrasonic power is 600W. After the ultrasonic is finished, take out the hub, and then spray the surface of the hub with the mixed solution. Repeat the spraying for 2 to 3 times. After the spraying is over, rinse the surface of the hub with hot water at a temperature of 45°C. , the flushing process is carried out according to the spray pressure of 0.2MPa and the flushing time of 1min, and the flushing is repeated several times to wash off the...

Embodiment 3

[0035] A wheel hub surface pretreatment process, comprising the following steps:

[0036] (1) Hot water washing: put the wheel hub in a washing tank, soak the wheel hub with hot water at a temperature of 70°C, soak for 10 minutes, and then use a brush to wipe off the aluminum chips and dust on the surface of the wheel hub;

[0037] (2) Degreasing treatment: place the wheel hub in a washing tank, soak the wheel hub in a mixture of water, concentrated cleaning agent and surfactant, and 1.5 wt% potassium hydroxide solution, and perform ultrasonic treatment for 12 minutes , the ultrasonic power is 450W. After the ultrasonic wave is over, take out the hub, and then spray the surface of the hub with the mixed solution. Repeat the spraying for 2 to 3 times. Washing, the washing process is carried out according to the spray pressure of 0.2MPa and the washing time of 1.5min. Repeat the washing for many times to wash away the residual mixed solution on the surface of the hub;

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com