Graphene heating oil and preparation method thereof

A technology of graphene and heating oil, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of oil overheating, heat exchange, high oil temperature, etc., to achieve automatic operation, prolong the service life of oil, The effect of preventing premature aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are described in detail below, and the embodiments described below are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

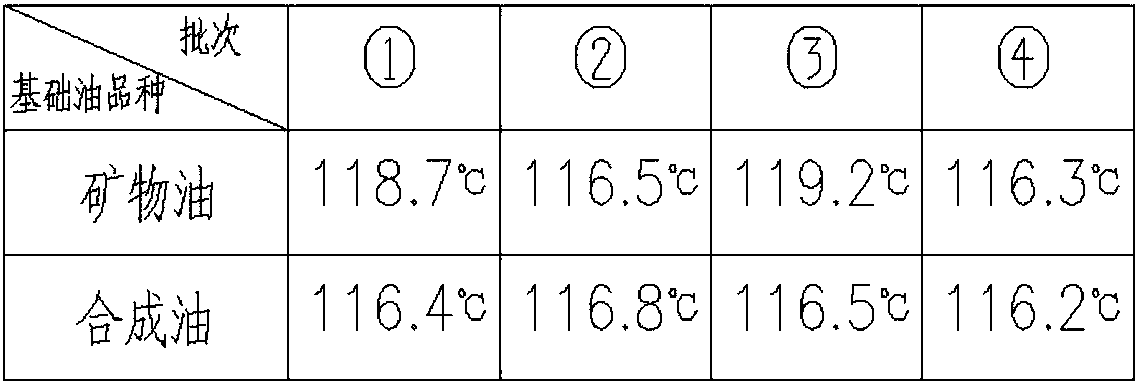

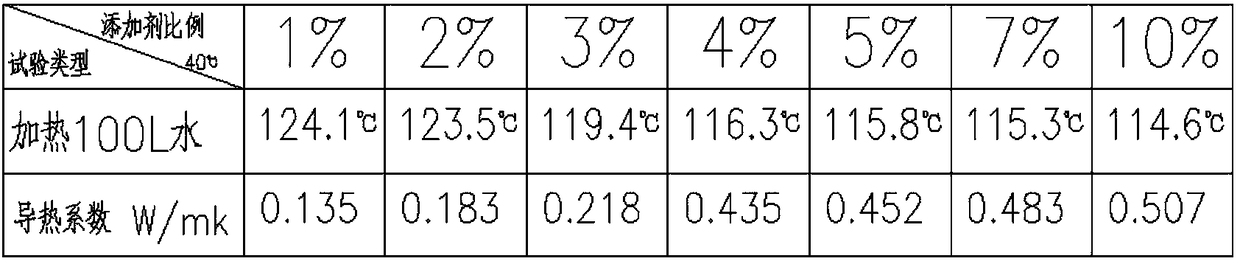

[0014] A graphene heating oil, comprising a base oil of 93%-97% by weight and a graphene additive of 3%-7% by weight, and the sum of the two is 100%, the base oil adopts alkylated aromatic hydrocarbon or The base oil of alkyl-substituted aromatic hydrocarbons, the graphene additive component includes graphene, dispersant, anti-oxidant and anti-corrosion agent, anti-rust agent and metal deactivator.

[0015] A method for preparing graphene heating oil. Using mixing heating and vibration equipment, first pump the barreled base oil into the mixing heating furnace, and at the same time pour a certain proportion of graphene additive into the furnace, turn on the stirrer and heat it to 100°C After heat preservation for 1 hour, the viscosity dropped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com