PET (Polyethylene Terephthalate) protection film for cover plate glass manufacturing procedure or delivery process and preparation method thereof

A cover glass, protective film technology, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, adhesive type, etc. and other problems, to achieve stable surface resistance value, solve the effect of poor scratch resistance and small increase in peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

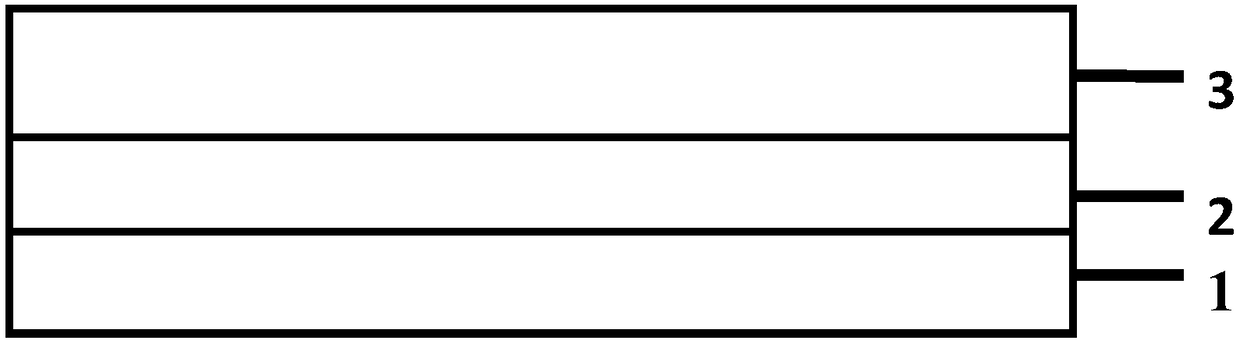

Image

Examples

Embodiment 1

[0025] 50 parts of polyurethane acrylate with 2 functionalities, molecular weight of 8000 and glass transition temperature of -50°C, 30 parts of isocylacrylate, 20 parts of caprolactone acrylate, 3 parts of trimethylol triacrylate, 2 One part of 1-hydroxycyclohexyl phenyl ketone, 0.5 part of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 0.5 part of lithium perchlorate were mixed and stirred evenly, and filtered to obtain solvent-free UV curing Low peeling antistatic pressure sensitive adhesive A.

[0026] Coat pressure-sensitive adhesive A on a 50um optical PET substrate with a coating thickness of 10um and UV energy of 150 mj / cm 2 After the conditions are cured, the 50um PET non-silicon release film is pasted, and the 180-degree peeling force of the obtained protective film is 5g / 25mm, and the surface resistance value is 10 9 Ω, the prepared protective film is pasted on a 5-inch cover glass, after aging at 150°C, there is no pollution and no residue, and the peeling fo...

Embodiment 2

[0028] Coat pressure-sensitive adhesive A on a 50um optical PET substrate with a coating thickness of 20um and UV energy of 300 mj / cm 2 After the conditions are cured, the 50um PET non-silicon release film is pasted, and the 180-degree peeling force of the obtained protective film is 8g / 25mm, and the surface resistance value is 10 9 Ω, the prepared protective film is attached to a 5-inch cover glass, after aging at 150°C, there is no pollution, no residue, and the peeling force after high temperature is 25g / 25mm.

Embodiment 3

[0030] 40 parts of 2-functionality, molecular weight of 5000, glass transition temperature of -40 ℃ polyurethane acrylate, 30 parts of octyl acrylate, 25 parts of ethoxylated ethyl ethacrylate, 5 parts of trimethylol triacrylate , 2 parts of 1-hydroxycyclohexyl phenyl ketone, 0.5 part of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and 0.5 part of lithium perchlorate were mixed and stirred evenly to obtain a solvent-free UV curing low Peel off the antistatic PSA B.

[0031] Coat the pressure-sensitive adhesive B on the 50um optical PET substrate, the coating thickness is 15um, and the UV energy is 300 mj / cm 2 After the conditions are cured, the 50um PET non-silicon release film is pasted, and the 180-degree peeling force of the obtained protective film is 3g / 25mm, and the surface resistance value is 10 8 Ω, the prepared protective film is attached to a 5-inch cover glass, after aging at 150°C, there is no pollution and no residue, and the peeling force after high temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com