Cathode interface modification material, and solar cell as well as preparation method and application thereof

A solar cell and cathode interface technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency and low carrier mobility, achieve low cost, improve luminous efficiency, and reduce work function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

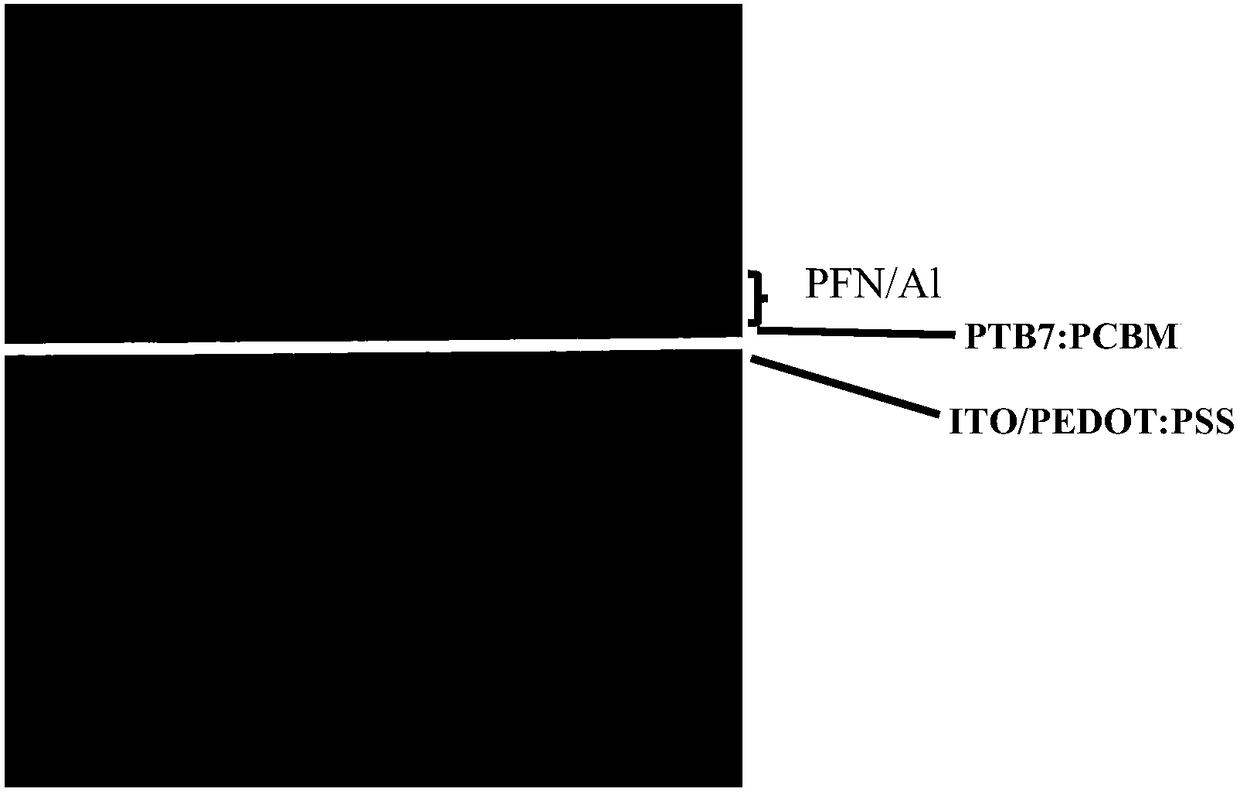

[0075] 1. ITO glass cleaning. Use glass cleaning solution, deionized water, acetone, absolute ethanol, and isopropanol for ultrasonic cleaning for 30 minutes. Blow dry the surface with nitrogen and carry out plasma surface treatment to make the surface cleaner and enhance wettability.

[0076] 2. Preparation of hole transport layer. PEDOT:PSS was spin-coated on the surface of ITO glass at a spin-coating speed of 3500 rpm for 60 seconds. After spin-coating, it was thermally annealed at 100°C for 30 minutes on a heating table.

[0077] 3. Film preparation of light-absorbing active layer. PTB7:PCBM was weighed according to a mass ratio of 1:4, and chlorobenzene was used as an organic solvent to prepare a light-absorbing active layer precursor solution. The precursor solution was spin-coated on the hole transport layer at a rotation speed of 600 rpm, and the spin-coating time was 1 min.

[0078] 4. Preparation of cathode interface modification layer. The PFN material was diss...

Embodiment 2

[0086] 1. ITO glass cleaning. Use glass cleaning solution, deionized water, acetone, absolute ethanol, and isopropanol for ultrasonic cleaning for 30 minutes. Blow dry the surface with nitrogen and carry out plasma surface treatment to make the surface cleaner and enhance wettability.

[0087] 2. Preparation of hole transport layer. PEDOT:PSS was spin-coated on the surface of ITO glass at a spin-coating speed of 3500 rpm for 60 seconds. After spin-coating, it was thermally annealed at 100°C for 30 minutes on a heating table.

[0088] 3. Film preparation of light-absorbing active layer. PTB7:PCBM was weighed according to the mass ratio of 1:4, and chlorobenzene was used as an organic solvent to prepare a light-absorbing active layer precursor solution, and the precursor solution was spin-coated on the hole transport layer at a rotation speed of 600 rpm. The spin coating time was 1 minute.

[0089] 4. Preparation of cathode interface modification layer. Dissolve 5 mg / ml PFN...

Embodiment 3

[0092] 1. ITO cleaning. Ultrasonic cleaning was performed for 30 minutes with glass cleaning solution, deionized water, acetone, absolute ethanol, and isopropanol successively. Blow dry the surface with nitrogen and carry out plasma surface treatment to make the surface cleaner and enhance wettability.

[0093] 2. Preparation of MoO 3 Floor. Put the glass sheet into the vacuum evaporation apparatus, and vacuumize to 3*10 -4 Pa, then in MoO was prepared at an evaporation rate of 3 layer with a thickness of 8 nm.

[0094]3. Spin-coat the photoactive layer. PTB7:PCBM was weighed according to a mass ratio of 1:4, and chlorobenzene was used as an organic solvent to prepare a light-absorbing active layer precursor solution. The precursor solution was spin-coated on the hole transport layer at a rotation speed of 600 rpm, and the spin-coating time was 1 min.

[0095] 4. Preparation of cathode interface modification layer. Dissolve 10mg / ml PFN-Br material in a highly polar s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com