Guaiazulene and extraction process thereof

A technology of guaiazulene and extraction process, which is applied in the field of extracting guaiazulene, can solve problems such as unsuitability for industrialized batch production, limited guaiazulene amount, difficult separation of guaiazulene, etc., and achieve High marketing value, promote wound healing, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

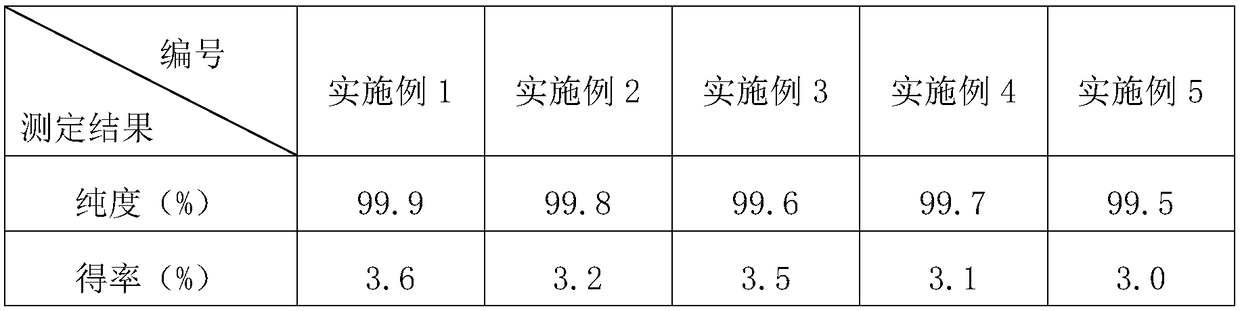

Examples

Embodiment 1

[0032] (1) Put 2000kg of natural essence and fragrance oil containing azulene compounds into a fractionation still, distill by steam distillation, and then fractionate under reduced pressure, collect the cuts at 125°C in a vacuum environment to obtain guaiazulene-containing oil fraction A of hydrocarbons;

[0033] (2) Inhale 800 kg of the obtained fraction A into a vacuum dehydration reactor, and simultaneously add 24 kg of boric acid, slowly heat to 200° C., carry out dehydration treatment, and then undergo vacuum distillation to obtain fraction B after the reaction is completed;

[0034] (3) Inhale 720 kg of the obtained fraction B in the dehydrogenation reactor, and add 144 kg of sulfur as a catalyst at the same time, heat to 210 ° C, carry out dehydrogenation treatment, after the reaction is completed, cool, and then inhale in the vacuum still, heat Distill at 210°C to obtain a blue oil-containing hydrocarbon mixture;

[0035] (4) After cooling the gained blue oleo hydroc...

Embodiment 2

[0041] (1) Put 2000kg of natural essence and fragrance oil containing azulene compounds into a fractionation still, distill by steam distillation, and then fractionate under reduced pressure, collect the cuts at 124°C in a vacuum environment to obtain guaiazulene-containing oil fraction A of hydrocarbons;

[0042] (2) Inhale 800 kg of the obtained fraction A in the vacuum dehydration reactor, and add 8 kg of sulfuric acid at the same time, slowly heat to 210° C., carry out dehydration treatment, and after the reaction is completed, then undergo vacuum distillation to obtain the fraction B;

[0043] (3) Inhale 720 kg of the obtained fraction B into the dehydrogenation reactor, and simultaneously add 36 kg of sulfur as a catalyst, heat to 220 ° C, and perform dehydrogenation treatment. Distill at 220°C to obtain a mixed liquid containing blue oil and hydrocarbons;

[0044] (4) After cooling the obtained blue oleohydrocarbon mixed solution 570kg to room temperature, add 160kg an...

Embodiment 3

[0050] (1) Put 1000kg of natural essence and fragrance oil containing azulene compounds into a fractionation still, distill by steam distillation, and then fractionate under reduced pressure, collect the fractions at 120°C in a vacuum environment to obtain guaiazulene-containing oil fraction A of hydrocarbons;

[0051] (2) Inhale 400 kg of the obtained fraction A into a vacuum dehydration reactor, and simultaneously add 8 kg of boric acid, slowly heat to 200° C., carry out dehydration treatment, and then undergo vacuum distillation to obtain fraction B after the reaction is completed;

[0052] (3) Inhale 360 kg of the obtained fraction B in the dehydrogenation reactor, and add 54 kg of sulfur as a catalyst at the same time, heat to 220 ° C, carry out dehydrogenation treatment, after the reaction is completed, cool, and then inhale in the vacuum still, heat Distill at 220°C to obtain a mixed liquid containing blue oil and hydrocarbons;

[0053] (4) After cooling the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com