Method for preparing CPP fiber-containing phosphate bone cement composite material

A technology of composite materials and bone cement, which is applied in the fields of pharmaceutical formulation, medical science, capsule delivery, etc., can solve the problems of mismatching new bone growth rate, inflammatory response, high brittleness, etc., achieve high strength, control drug release, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

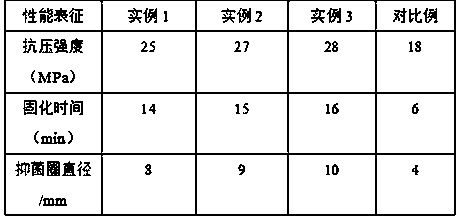

Examples

example 1

[0022] Dissolve chitosan powder in 2% acetic acid solution to make a 1.5% chitosan-acetic acid solution, preheat the 15% gelatin solution and liquid paraffin to 50°C to obtain the preheated After heating, the mass fraction is 15% gelatin solution and preheated liquid paraffin, and the mass fraction is 1.5% chitosan-acetic acid solution and the preheated mass fraction is 15% gelatin solution mixed evenly by volume ratio 1:1 , to obtain mixed solution A; mix Span-80 and Tween-80 uniformly at a mass ratio of 1:1 to obtain a composite emulsifier; add the composite emulsifier to liquid paraffin at a mass ratio of 1:10 to obtain an emulsion, and obtain an emulsion by mass ratio Add the mixed solution A to the emulsion dropwise at 1:5, stir at room temperature for 2 hours at a stirring speed of 1500r / min to obtain the mixed solution B, and centrifuge the mixed solution B at a centrifugal radius of 7cm and a rotating speed of 1000r / min for 5min to obtain a precipitate , the precipitat...

example 2

[0024]Dissolve chitosan powder in 2% acetic acid solution to make a 1.5% chitosan-acetic acid solution, preheat the 15% gelatin solution and liquid paraffin to 50°C to obtain the preheated After heating, the mass fraction is 15% gelatin solution and preheated liquid paraffin, and the mass fraction is 1.5% chitosan-acetic acid solution and the preheated mass fraction is 15% gelatin solution mixed evenly by volume ratio 1:1 , to obtain mixed solution A; mix Span-80 and Tween-80 uniformly at a mass ratio of 1:1 to obtain a composite emulsifier; add the composite emulsifier to liquid paraffin at a mass ratio of 1:10 to obtain an emulsion, and obtain an emulsion by mass ratio Add the mixed solution A to the emulsion dropwise at 1:5, stir at room temperature for 2.5 hours at a stirring speed of 1750r / min to obtain a mixed solution B, and centrifuge the mixed solution B at a centrifugal radius of 11cm and a rotating speed of 1250r / min for 8min to obtain a precipitate The precipitate ...

example 3

[0026] Dissolve chitosan powder in 2% acetic acid solution to make a 1.5% chitosan-acetic acid solution, preheat the 15% gelatin solution and liquid paraffin to 50°C to obtain the preheated After heating, the mass fraction is 15% gelatin solution and preheated liquid paraffin, and the mass fraction is 1.5% chitosan-acetic acid solution and the preheated mass fraction is 15% gelatin solution mixed evenly by volume ratio 1:1 , to obtain mixed solution A; mix Span-80 and Tween-80 uniformly at a mass ratio of 1:1 to obtain a composite emulsifier; add the composite emulsifier to liquid paraffin at a mass ratio of 1:10 to obtain an emulsion, and obtain an emulsion by mass ratio Add the mixed solution A to the emulsion at a ratio of 1:5, and stir at room temperature for 3 hours at a stirring speed of 2000r / min to obtain a mixed solution B. Centrifuge the mixed solution B at a centrifugal radius of 14cm and a rotational speed of 1500r / min for 10min to obtain a precipitate , the precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com