Oil cooked shrimp and manufacturing method thereof

A technology of stewing and lobster, which is applied in the field of braised shrimp and its production, can solve the problems affecting the freshness and flavor of crayfish, the lagging of crayfish processing technology, and the high bacterial content of crayfish, so as to achieve the improvement and improvement of taste and nutritional components, The effect of promoting gastrointestinal digestion and keeping the bacteria content from deteriorating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

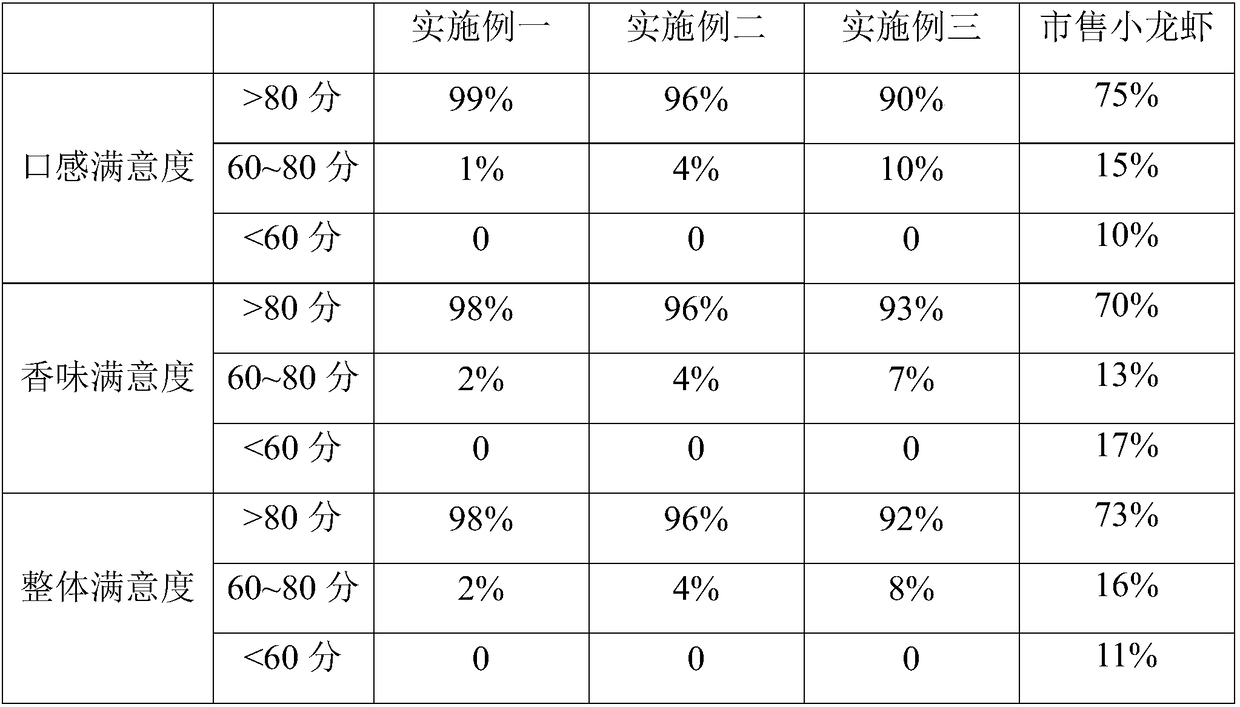

Examples

preparation example Construction

[0023] In addition, the applicant specially designed a preparation method for the braised shrimp provided by the present invention, which includes the following steps:

[0024] S101: Select live prawns from Qianjiang paddy fields with a head-to-tail ratio of about 1:1, plump and firm tails, and a weight of 20 to 100 g. Then wash the prawns’ heads with running water and a soft brush Then brush the abdomen of the shrimp and the tail of the shrimp to remove impurities; then use stainless steel scissors to cut off the head of the shrimp first, then use the scissors to pick out the liver of the shrimp completely, then cut off the legs of the shrimp, and then use the flowing Rinse repeatedly with clean water.

[0025] S102: Boil seasoning oil (ingredients are edible oil, ginger, Chinese prickly ash, chili, cinnamon, star anise, white buckle and grass fruit), keep stirring during the process, and keep simmering for 20-50 minutes; boil bean paste, during Stir constantly, and keep boi...

Embodiment 1

[0031] This embodiment provides a kind of braised shrimp in oil. The raw material components are based on 6000 parts by weight of crayfish, including: 4000 parts by weight of water, 1000 parts by weight of edible oil, 500 parts by weight of bean paste, 150 parts by weight of cooking wine, and 200 parts by weight of ginger 100 parts by weight of garlic, 200 parts by weight of white sugar, 50 parts by weight of edible salt, 80 parts by weight of sweet noodle sauce, 20 parts by weight of black pepper, 50 parts by weight of thirteen spices, 10 parts by weight of monosodium glutamate, 30 parts by weight of chicken essence, 10 parts by weight of Chinese prickly ash , 30 parts by weight of raw powder, 10 parts by weight of green onion, 20 parts by weight of pepper, 2 parts by weight of Angelica dahurica, 10 parts by weight of old buckle, 1 part by weight of ginger, 10 parts by weight of cinnamon, 1 part by weight of star anise, 10 parts by weight of grass fruit, 10 parts by weight of ...

Embodiment 2

[0039] This embodiment provides a kind of braised shrimp in oil. The raw material components are based on 6000 parts by weight of crayfish, including: 3000 parts by weight of water, 2000 parts by weight of edible oil, 300 parts by weight of bean paste, 300 parts by weight of cooking wine, and 100 parts by weight of ginger , 200 parts by weight of garlic, 100 parts by weight of white sugar, 100 parts by weight of edible salt, 30 parts by weight of sweet noodle sauce, 50 parts by weight of black pepper, 20 parts by weight of thirteen spices, 30 parts by weight of monosodium glutamate, 10 parts by weight of chicken essence, 30 parts by weight of Chinese prickly ash , 10 parts by weight of raw powder, 30 parts by weight of green onion, 5 parts by weight of pepper, 10 parts by weight of Angelica dahurica, 1 part by weight of old buckle, 10 parts by weight of ginger, 1 part by weight of cinnamon bark, 10 parts by weight of star anise, 1 part by weight of grass fruit, 1 part by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com