A kind of processing method of mugwort tea

A processing method and technology of mugwort tea, which is applied in the processing field of mugwort tea, can solve problems such as the unsatisfactory dissolution rate of mugwort nutrient components, restrict the development of mugwort tea, and the loss of nutrients, and achieve good sensory quality, storage effect, and good clarity , the effect of preventing nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

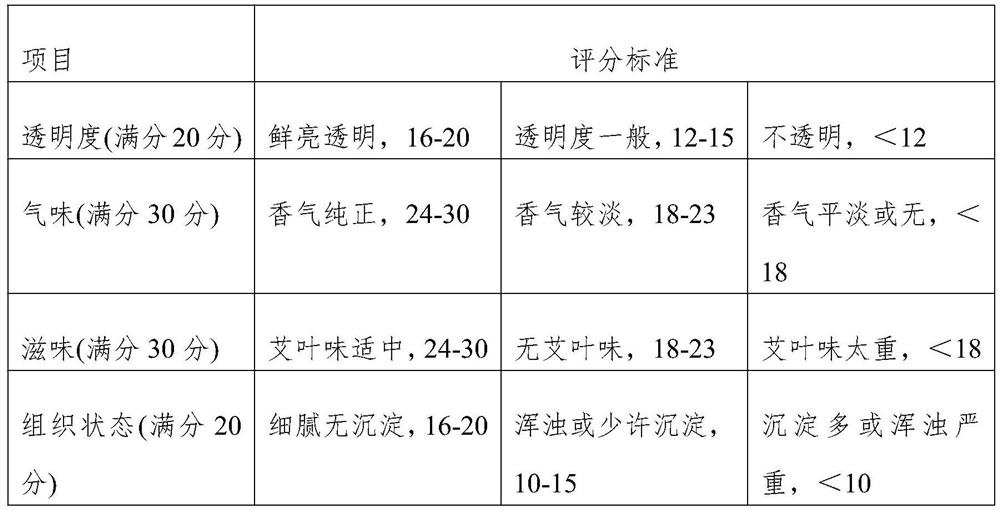

Examples

Embodiment 1

[0020] A processing method of mugwort tea, which is made by natural drying, natural withering, steam treatment, pulverization, extraction, electric field treatment, concentration, and spray drying of mugwort leaves, wherein the electric field treatment is carried out at an electric field strength of 0.8 kV / cm, electric field frequency 12kHz for 5min, electric field strength 2.1kV / cm, electric field frequency 26kHz for 13min, electric field strength 1.5kV / cm, electric frequency 19kHz 7min;

[0021] The steam treatment is a steam treatment at a temperature of 100°C for 15 minutes, and then a steam treatment at a temperature of 140°C for 8 minutes;

[0022] The pulverization is to grind Folium Artemisiae Argyi to cross 140 mesh sieves;

[0023] The extraction is to mix the leaves of Artemisia argyi and the extraction agent according to the ratio of solid to liquid ratio of 1:23, first heat to 85°C for constant temperature extraction for 2 hours, and then heat up to 100°C for con...

Embodiment 2

[0029] A processing method of mugwort tea, which is made by natural sun-drying, natural withering, steam treatment, pulverization, extraction, electric field treatment, concentration and spray-drying steps of mugwort leaves, wherein the electric field treatment is carried out at an electric field strength of 0.7 kV / cm and electric field frequency 11kHz for 3min, electric field strength 1.9kV / cm and electric frequency 24kHz for 12min, electric field strength 1.4kV / cm and electric frequency 18kHz 6min;

[0030] The steam treatment is a steam treatment at a temperature of 88°C for 10 minutes, and then a steam treatment at a temperature of 120°C for 7 minutes;

[0031] The pulverization is to grind Folium Artemisiae Argyi to cross 120 mesh sieves;

[0032] The extraction is to mix the leaves of Artemisia argyi and the extraction agent according to the ratio of material to liquid of 1:18, first heat to 78°C for constant temperature extraction for 1 hour, and then heat up to 90°C f...

Embodiment 3

[0038] A processing method of mugwort leaf tea, which is made by natural drying, natural withering, steam treatment, pulverization, extraction, electric field treatment, concentration and spray drying of mugwort leaves, wherein the electric field treatment is performed at an electric field strength of 0.75 kV / cm and electric field frequency 12kHz for 4min, electric field strength 2kV / cm and electric frequency 25kHz for 12min, electric field strength 1.4kV / cm and electric frequency 19kHz for 7min ;

[0039] The steam treatment is a steam treatment at a temperature of 93°C for 12 minutes, and then a steam treatment at a temperature of 130°C for 8 minutes;

[0040] The pulverization is to grind Folium Artemisiae Argyi to cross 130 mesh sieves;

[0041] The extraction is to mix the leaves of Artemisia argyi and the extraction agent according to the ratio of material to liquid of 1:20, first heat to 80°C for constant temperature extraction for 1.5h, and then heat up to 95°C for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com