Dumbbell rock sample preparation device and processing method

A technology for rock specimens and preparation devices, applied in the field of geological exploration, can solve the problems of weak processing capacity and bearing capacity, poor flexibility of processing equipment, poor stability of processing accuracy, etc., and achieves high versatility and bearing capacity, efficient and convenient replacement. , the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

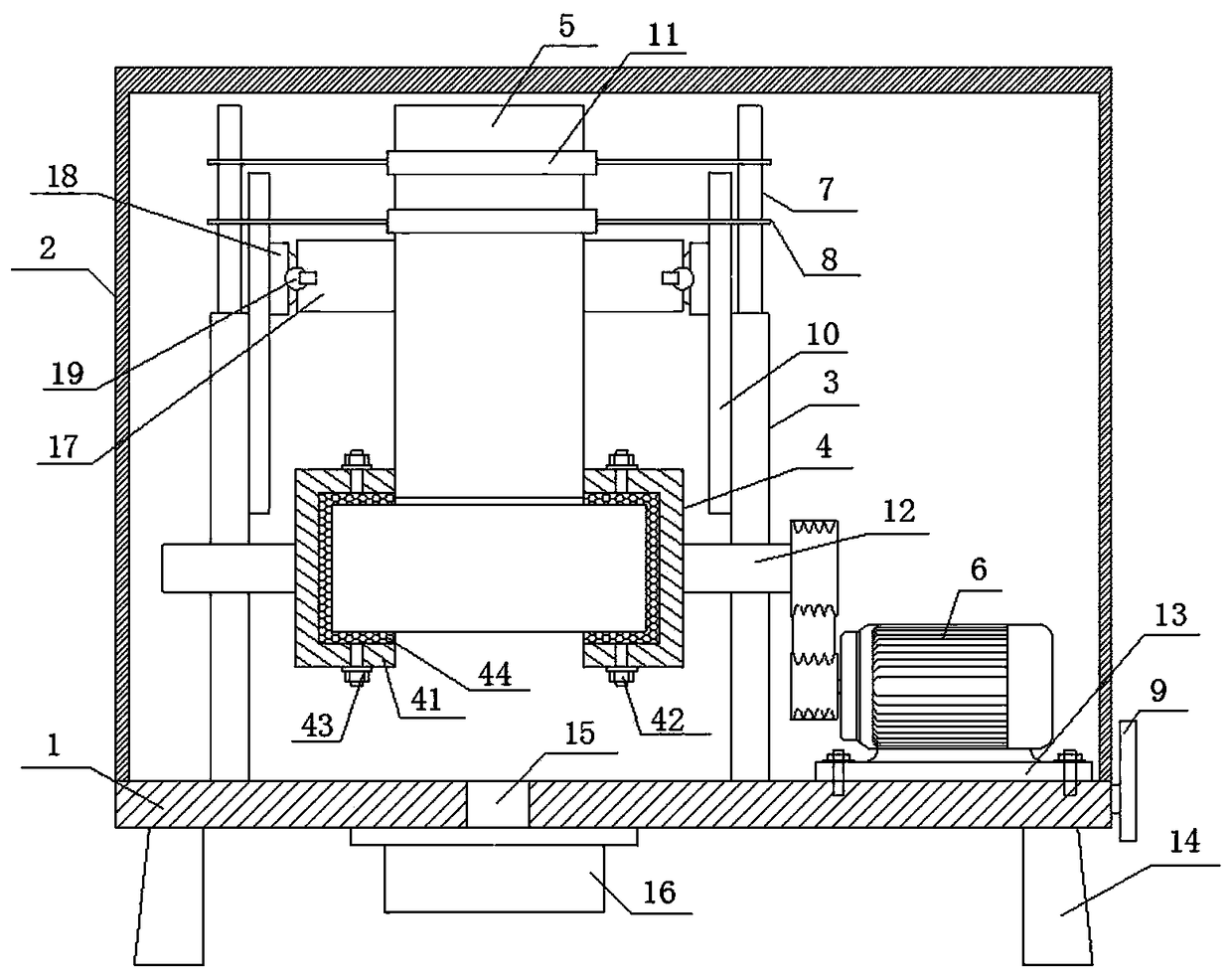

[0026] Such as figure 1 The device for preparing a dumbbell-shaped rock specimen comprises a base 1, a protective box 2, a fixed support 3, a rock sample clamp 4, a grinding tool 5, a drive motor 6, a micrometer 7, a scale scale 8 and a control circuit 9, and the base 1 is a plate-shaped structure with a rectangular cross-section and distributed parallel to the horizontal plane. The protective box 2 is covered on the outside of the base 1 and forms a closed cavity structure with the base 1. The fixing bracket 3 is installed on the upper end surface of the base 1 and connected with the base. 1. A coaxially distributed frame structure. The grinding tool 5 is located directly above the base 1 and coaxially distributed with the base 1. The side surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com