Wire-tube composite structure used for evaporation and condensation of inner surface

A technology of evaporative condensation and composite structure, which is applied in the direction of evaporator/condenser, refrigerator, tubular element, etc., can solve the problems of difficult conduction, time lag, etc., and achieve the purpose of increasing the contact area, promoting generation and condensation, and cheap materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

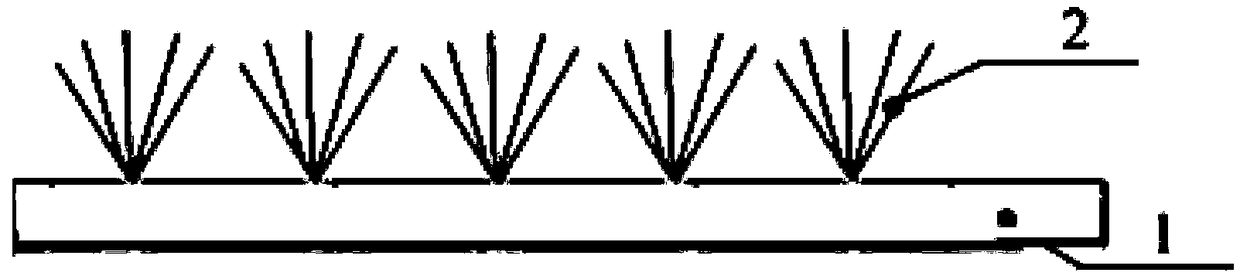

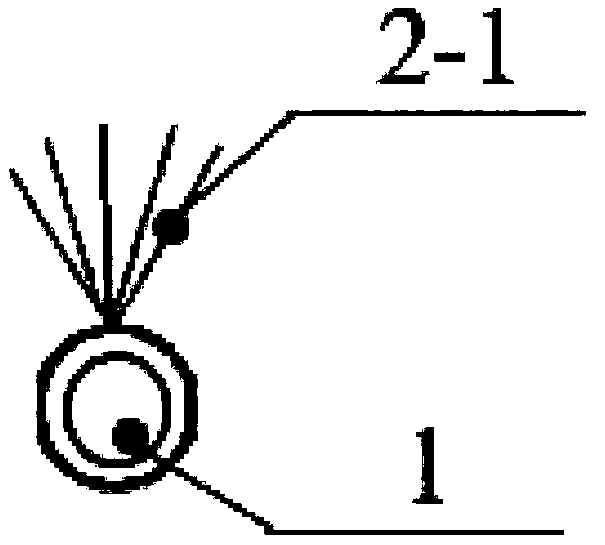

[0032] Combine below Figure 1-13 To illustrate this embodiment, the present invention relates to the field of evaporative condenser technology and seawater desalination technology, more specifically, a wire tube composite structure for evaporation and condensation on the inner surface, including a condensing copper tube 1 and a copper wire bundle 2 attached to the tube, It can effectively solve the problem that the water vapor generated by the steam generator in the prior art is treated for the same time. The tiny droplets appearing on the surface of the two-dimensional fins lag in time, and the droplets merge with each other when the number is small and the time is longer. , forming a liquid film locally, which is not easy to lead away. The present invention adopts a one-dimensional linear heat-conducting material, such as copper wire, which is combined with a copper tube to form the main body of the present invention. The needle-shaped tube-attached bundle-shaped copper wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com