Production technology for siro compact spinning combed cotton and cellulosic fiber blended yarn

A cellulose fiber and siro compact technology, applied in the production process of siro compact spun combed cotton and cellulose fiber blended yarn, to achieve the effect of increasing added value and profit, comprehensive performance of home textiles, and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

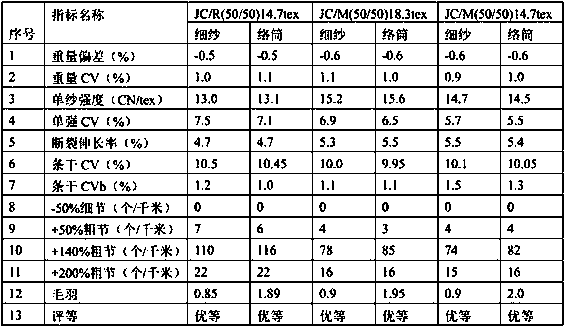

Examples

Embodiment

[0040] Whether the development and production are smooth and whether the quality of the finished product can reach the standard is the focus of carding, mixing and spinning. Because Tencel, Modal, etc., and differential chemical fiber spandex have certain difficulties in carding processing, and there are many types of reversing, so clean cotton is used to form rolls and 186 carding machines are used for processing. Due to the mass production of cotton and the color differences between teams, the blowing-carding and multi-bin process is adopted to ensure uniform mixing and prevent color difference. At the same time, "one machine and two channels" foreign fiber removal machine is used to improve the foreign fiber removal effect .

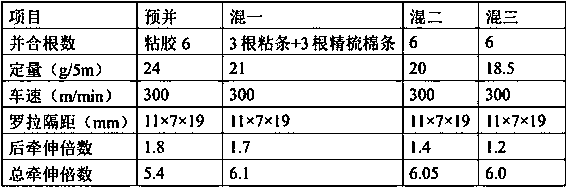

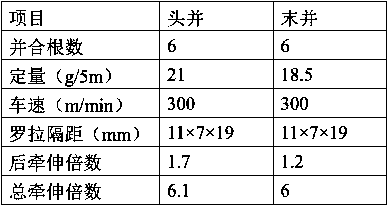

[0041]In order to improve the uniformity of sticking, ensure the correct blending ratio, and prevent color difference, cellulose fibers and differentiated chemical fiber strips are all pre-merged, and then mixed with cotton for three-way blending. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com