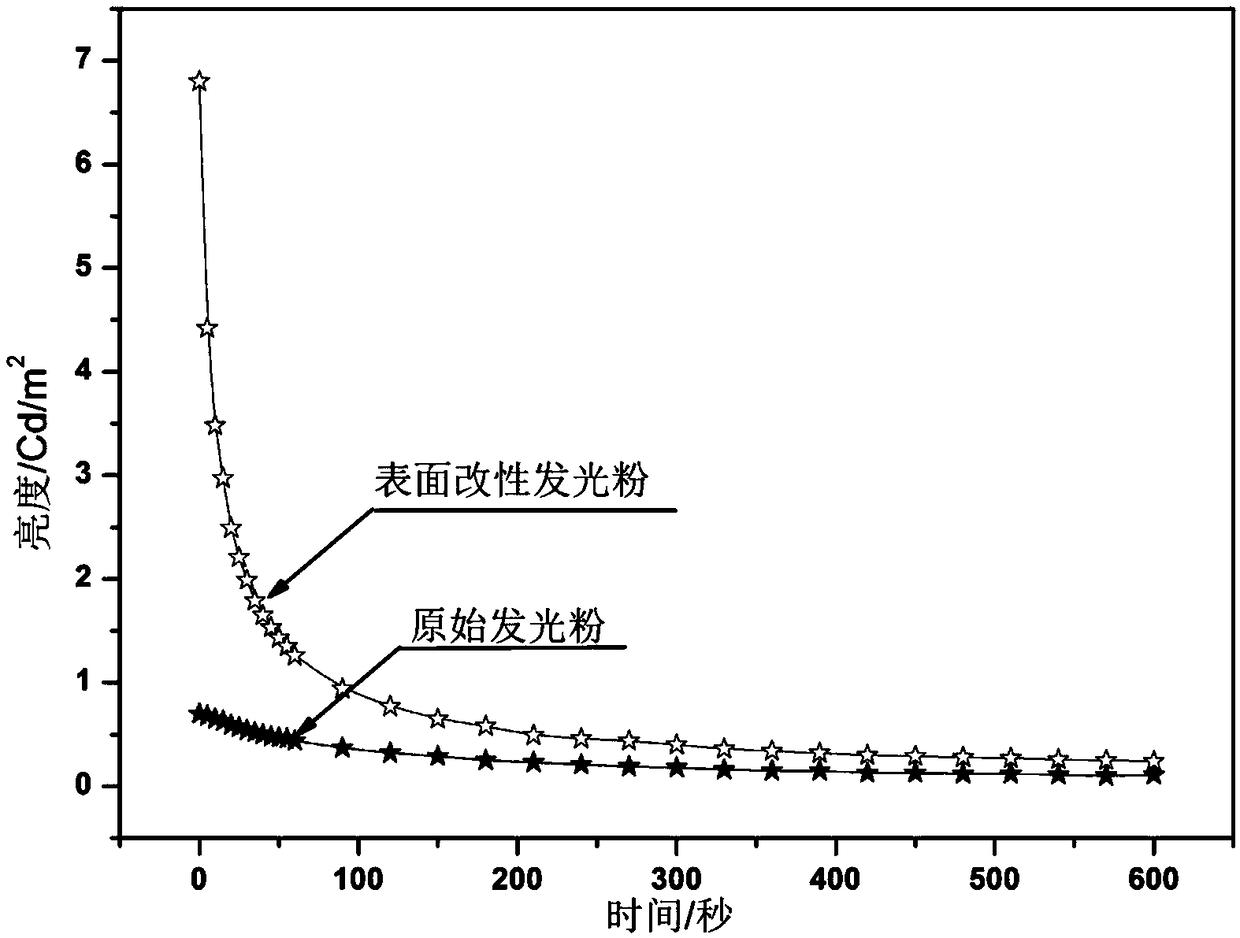

Method for improving luminescent property of aluminate long-lasting phosphor material

A technology with long afterglow luminescence and luminescence performance, applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effect of simple synthesis process, strong operability and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, the SrAl 2 o 4 : Eu 2+ , Dy 3+ Pour the luminescent powder into the alcohol, so that the alcohol submerges the luminescent powder, sonicate in the ultrasonic instrument for 5 minutes, filter after the ultrasonic is completed, and dry in an oven at 100°C for 15 minutes;

[0037] Step 2, weigh the luminescent powder obtained in step 1 into a beaker, put the luminescent powder in absolute ethanol and stir evenly, wherein the mass ratio of luminescent powder to absolute ethanol is 1:1; then add tetraethyl orthosilicate solution 2mL, add 0.2mL of 1mol / L dilute nitric acid dropwise, stir for 30min, slowly add ammonia diluted with absolute ethanol dropwise to adjust the pH to 7, and stir until the solution is in a gel state. The obtained gel was dried in an oven at 60°C for 14 hours, and ground to obtain a silica-coated luminescent material;

[0038] Step 3, silver nitrate is dissolved in alcohol to form a homogeneous solution, wherein the molar concentration of si...

Embodiment 2

[0046] Step 1, the SrAl 2 o 4 : Eu 2+ , Dy 3+ Pour the luminescent powder into alcohol, so that the alcohol submerges the luminescent powder, sonicate in an ultrasonic instrument for 7 minutes, filter after the ultrasonic is completed, and dry in an oven at 115°C for 18 minutes;

[0047] Step 2, weigh the luminescent powder obtained in step 1 into a beaker, put the luminescent powder in absolute ethanol and stir evenly, wherein the mass ratio of luminescent powder to absolute ethanol is 1:1.5; then add tetraethyl orthosilicate solution 3mL, add 0.3mL of 1mol / L dilute nitric acid dropwise, stir for 35min, slowly add ammonia water diluted with absolute ethanol dropwise to adjust the pH value to 7.5 and stir until the solution is in a gel state. The obtained gel was dried in an oven at 70°C for 10 hours, and ground to obtain a silica-coated luminescent material;

[0048] Step 3, silver nitrate is dissolved in alcohol to form a uniform solution, wherein the molar concentration...

Embodiment 3

[0053] Step 1, the SrAl 2 o 4 : Eu 2+ , Dy 3+ Pour the luminescent powder into alcohol, so that the alcohol submerges the luminescent powder, sonicate in the ultrasonic instrument for 8 minutes, filter after the ultrasonic is completed, and dry in an oven at 100°C for 20 minutes;

[0054] Step 2, weigh the luminescent powder obtained in step 1 into a beaker, place the luminescent powder in absolute ethanol and stir evenly, wherein the mass ratio of the luminescent powder to absolute ethanol is 1:2.5; then add tetraethyl orthosilicate Solution 3mL, dropwise add 0.3mL of 1mol / L dilute nitric acid, stir for 45min, slowly add dropwise ammonia water diluted with absolute ethanol to adjust the pH value to 8, stir until the solution is in a gel state. The obtained gel was dried in an oven at 60°C for 13 hours, and ground to obtain a silica-coated luminescent material;

[0055] Step 3, silver nitrate is dissolved in alcohol to form a homogeneous solution, wherein the molar concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com