Moisture content measuring device based on plug-in capacitive sensor

A capacitive sensor and measuring device technology, applied to measuring devices, material capacitance, instruments, etc., can solve problems such as inconvenient installation, complex structure, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and embodiments.

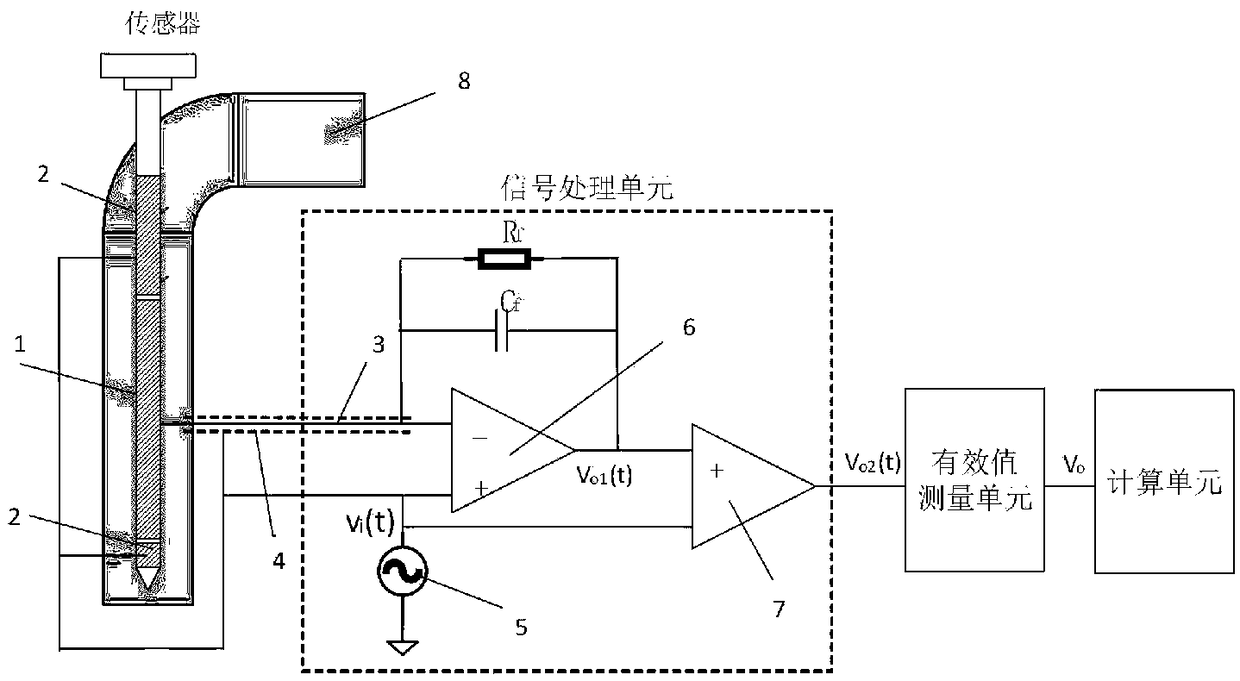

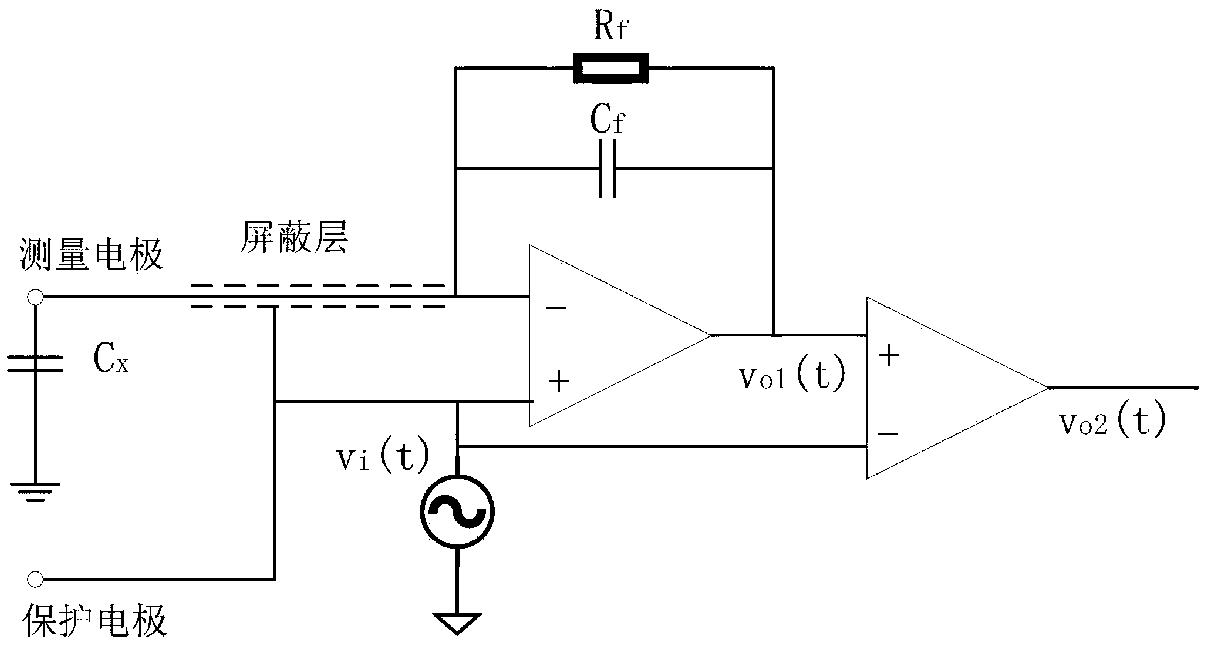

[0017] The present invention mainly includes the design of sensor design, signal processing unit, effective value measurement unit and calculation unit. The specific design is as follows:

[0018] 1. Sensor design

[0019] Such as figure 1 As shown, the plug-in capacitive sensor is composed of an excitation measuring electrode in the middle and two protective electrodes on the top and bottom. Among them, the excitation and measurement share the same electrode of the sensor, and the grounded metal pipe is used as the reference ground. When installing, the sensor is inserted from top to bottom along the vertical pipe direction so that the electrode is located at the axis of the vertical pipe. The excitation measurement electrode and the protection electrode of the sensor are respectively lead to the signal processing unit, and the lead adopts a shielded cable, which is led...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com