Catalytic combustion waste gas treatment system for medium and small air volumes

A technology for waste gas treatment and catalytic combustion, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of too fast empty bed flow rate of waste gas, uneven distribution of heating pipes, no supplementary cooling system, etc., to optimize catalytic combustion process, reduced heat loss, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

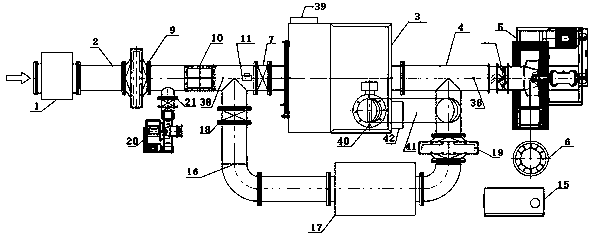

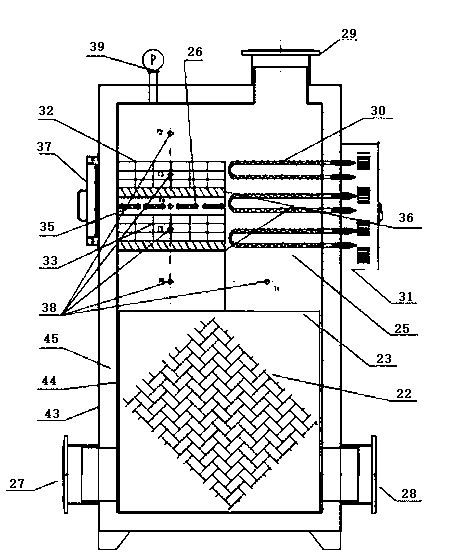

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the following Figure 1-2 The technical solutions of the present invention are further described with the examples.

[0030] It should be noted that the embodiments provided by the present invention are only for the purpose of effectively explaining the technical features of the present invention, and the positioning words such as the left side, the right side, the upper end, the lower end, etc. are only for the purpose of improving the embodiments of the present invention. The description should not be regarded as a limitation on the technical solution of the present invention.

[0031] The present invention is aimed at industrial air volume at 500m 3 / h~20000m 3 / h of the organic waste gas treatment industry, especially the waste treatment system that cannot contain chlorine, phosphorus, arsenic, sulfur, and mercury, tin, zinc and other substances that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com