Functional layer coating for projection screen, projection screen and manufacturing method thereof

A functional layer and screen technology, applied in the field of projection, can solve the problems of low contrast, low resolution, narrow viewing angle, etc., achieve the effect of blocking water vapor, simple production method, and improving contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for making a projection screen, comprising the following steps:

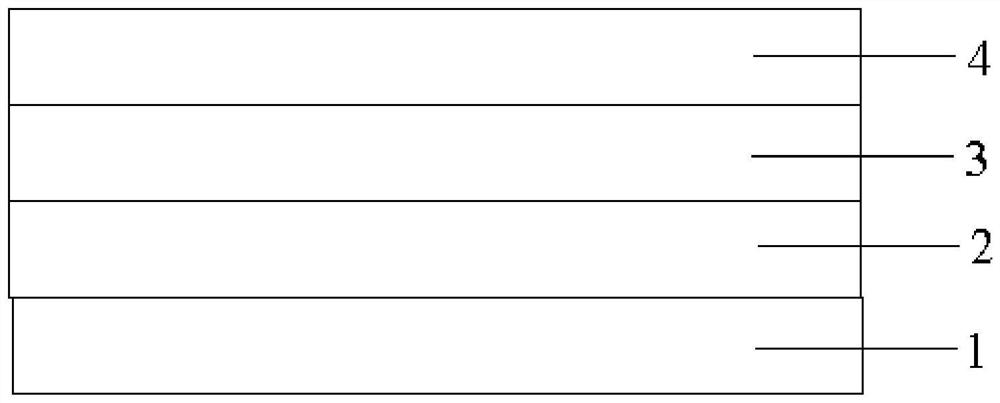

[0039] (1) Provide a base layer, the material of the base layer is PET, and the thickness of the base layer is 1mm;

[0040] (2) Coating a glass fiber layer of 0.3mm on one side of the base layer, depositing a protective layer on one side of the glass fiber layer, the material of the protective layer is a composite layer composed of silicon nitride and silicon carbide, and the thickness is 0.5mm;

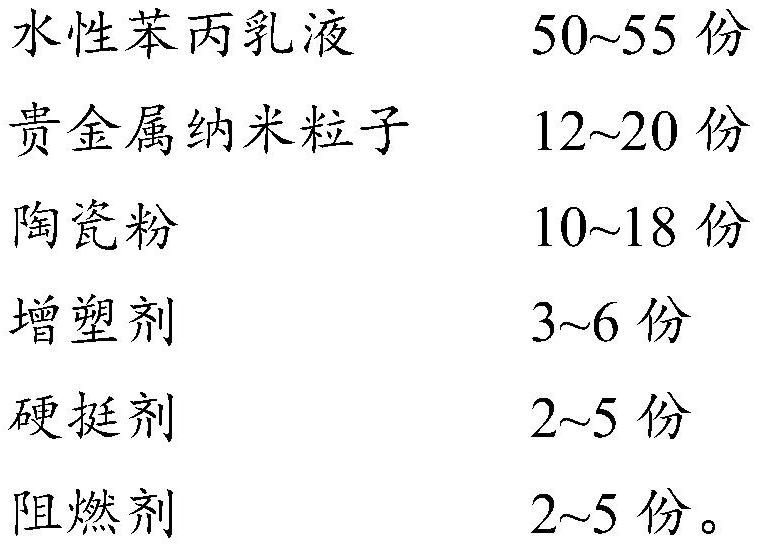

[0041] (3) Add 18 parts of precious metal nanoparticles and 15 parts of ceramic powder into 55 parts of water-based styrene-acrylic emulsion, raise the temperature to 75°C, oscillate ultrasonically for 15-30min, set the temperature to 50°C, add 5 parts of plasticizer, 4 1 part of stiffening agent and 2 parts of flame retardant, put into a disperser and stir at a speed of 500 rpm for 10-20 minutes to obtain a functional layer coating, which is coated on one side of the protective layer to form a functio...

Embodiment 2

[0043] A method for making a projection screen, comprising the following steps:

[0044] (1) Provide a base layer, the material of the base layer is PVC, and the thickness of the base layer is 1mm;

[0045] (2) Coating a glass fiber layer of 0.3 mm on one side of the base layer, depositing a protective layer on one side of the glass fiber layer, the material of the protective layer is aluminum oxide, and the thickness is 0.3 mm;

[0046] (3) Add 12 parts of precious metal nanoparticles and 10 parts of ceramic powder into 50 parts of water-based styrene-acrylic emulsion, raise the temperature to 85°C, ultrasonically oscillate for 15-30min, set the temperature to 60°C, add 4 parts of plasticizer, 3 1 part of stiffening agent and 4 parts of flame retardant, put into a disperser and stir at a speed of 500 rpm for 10-20 minutes to obtain a functional layer coating, which is coated on one side of the protective layer to form a functional layer , the thickness of the functional laye...

Embodiment 3

[0048] A method for making a projection screen, comprising the following steps:

[0049] (1) Provide a base layer, the material of the base layer is PVC, and the thickness of the base layer is 1mm;

[0050] (2) Coating a glass fiber layer of 0.3mm on one side of the base layer, depositing a protective layer on one side of the glass fiber layer, the material of the protective layer is a combined layer of silicon oxide and silicon carbide, and the thickness is 0.6mm;

[0051] (3) Add 20 parts of precious metal nanoparticles and 16 parts of ceramic powder into 53 parts of water-based styrene-acrylic emulsion, raise the temperature to 85°C, oscillate ultrasonically for 15-30min, set the temperature to 55°C, add 3 parts of plasticizer, 3 1 part of stiffening agent and 5 parts of flame retardant, put into a disperser and stir at a speed of 500 rpm for 10-20 minutes to obtain a functional layer coating, which is coated on one side of the protective layer to form a functional layer ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com