Heteroatom doped polymer nano-microsphere and preparation method thereof

A nano-microsphere and polymer technology, which is applied in the field of heteroatom-doped polymer nano-microspheres and the preparation thereof, can solve the problems of long time, high reaction temperature, complicated operation, etc. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

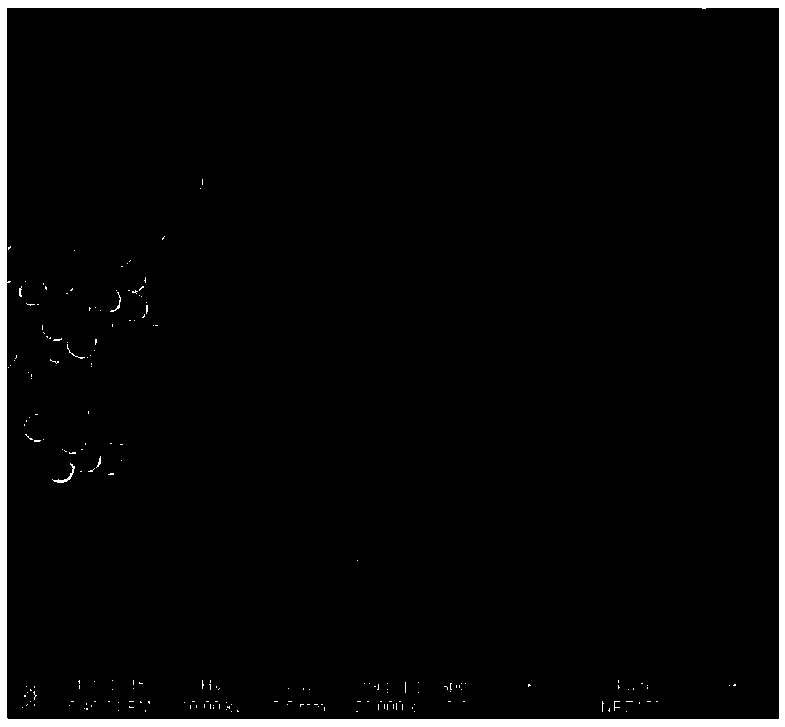

[0069] Dissolve 10g (0.08mol) of melamine and 3.01g (0.016mol) of 2,4-diaminobenzenesulfonic acid in 2000mL of water, add dropwise 5mL of ammonia water, stir at 25°C and 500rpm until the solution is uniform and transparent. Add 50 mL of formaldehyde solution, and after about 3 minutes, the liquid becomes obviously turbid. Keep at 25°C, stir at 500rpm for 2 hours, centrifuge, wash and dry, and observe with electron microscope, as shown in figure 1 As shown, the nano-microspheres are uniform, and the average particle diameter is 512nm.

Embodiment 2

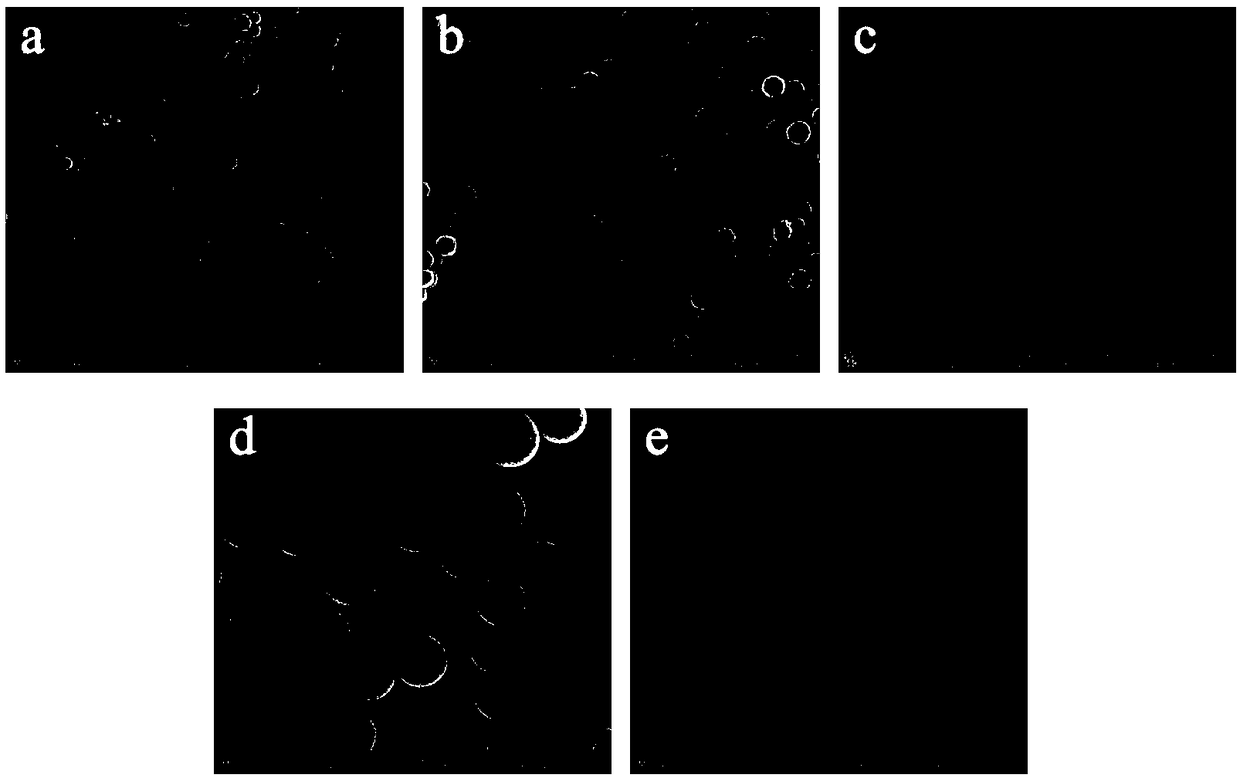

[0071] Dissolve 0.19g (0.0015mol) of melamine and 0.058g (0.0003mol) of 2,4-diaminobenzenesulfonic acid in 50mL of water, add 0.1mL of ammonia water dropwise, at 5°C, 15°C, 25°C, 35°C, 45°C Next, stir at a stirring speed of 500rpm until the solution is uniform and transparent. Add 1.2 mL of formaldehyde solution, and after about 45 seconds, the liquid turns from clear to cloudy. Keeping the temperature, stir at 500rpm for 2 hours. After the reaction is completed, centrifugation, washing, drying, and electron microscope observation are performed to obtain nitrogen-sulfur-containing polymer nanometer microspheres. Such as figure 2 As shown, the temperature conditions of a to e are 5°C, 15°C, 25°C, 35°C, and 45°C in sequence. The nanospheres are uniform and the average particle diameters are 148nm, 257nm, 513nm, 627nm, and 845nm.

Embodiment 3

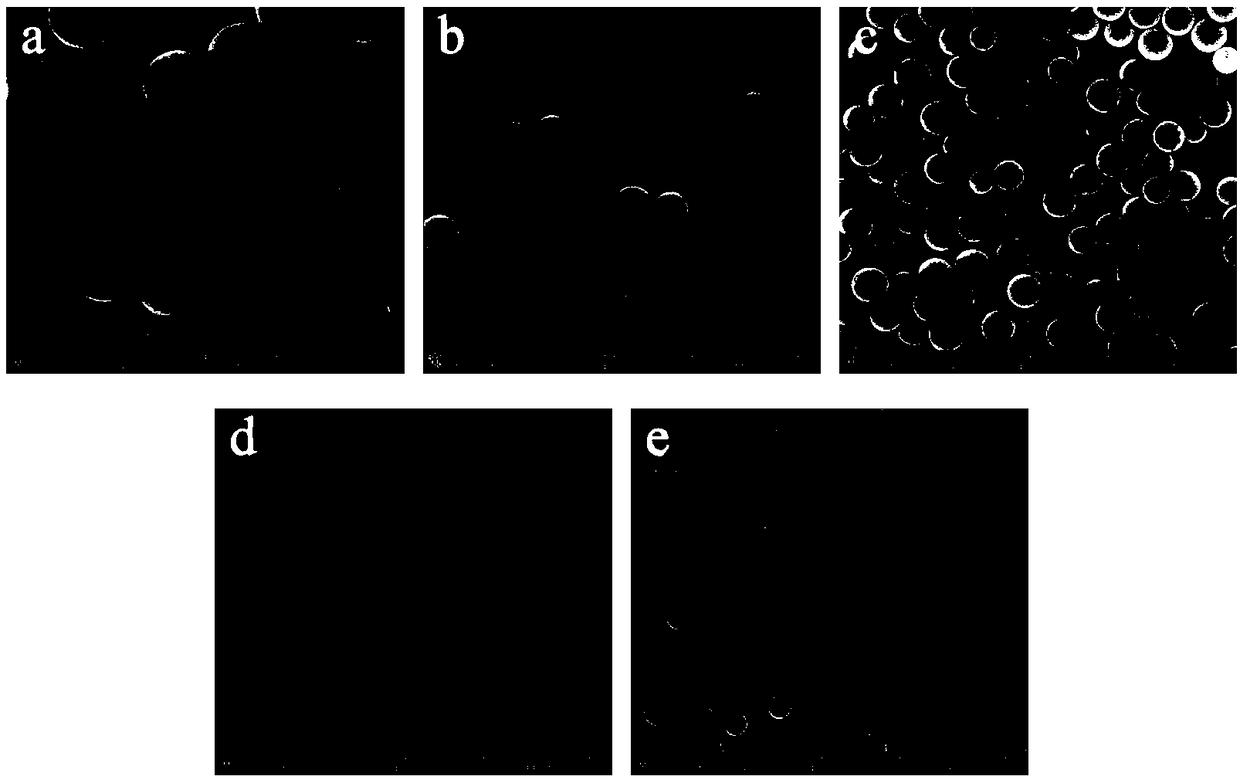

[0073] 0.19g (0.0015mol) melamine, 0.0145g (0.000075mol), 0.029g (0.00015mol), 0.058g (0.0003mol), 0.116g (0.0006mol), 0.174g (0.0009mol) 2,4-diaminobenzene Dissolve the sulfonic acid in 50mL of water, add 0.1mL of ammonia water dropwise, and stir at 25°C at a stirring speed of 500rpm until the solution is uniform and transparent. Add 1.2 mL of formaldehyde solution, and after about 45 seconds, the liquid turns from clear to cloudy. Keep at 25°C and stir at 500rpm for 2 hours. After the reaction is completed, centrifugation, washing, drying, and electron microscope observation are performed to obtain nitrogen-sulfur-containing polymer nanometer microspheres. Such as image 3 As shown, the dosage of a~e2,4-diaminobenzenesulfonic acid is 0.0145g (0.000075mol), 0.029g (0.00015mol), 0.058g (0.0003mol), 0.116g (0.0006mol), 0.174g (0.0009mol ), the nanospheres are uniform, and the average particle size is 793nm, 624nm, 496nm, 307nm, 169nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com