Preparation method of monodisperse hydrophobic poly(trifluoroethyl methacrylate) colloid emulsion

A technology of polytrifluoroethyl methacrylate and trifluoroethyl methacrylate is applied in the field of preparation of hydrophobic colloidal photonic crystal emulsion, and can solve the problem of inability to build long-range ordered stacking array structure, defects, unfavorable assembly and high performance. Photonic crystal materials and other problems, to achieve the effect of simple and effective preparation method and low monodispersity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

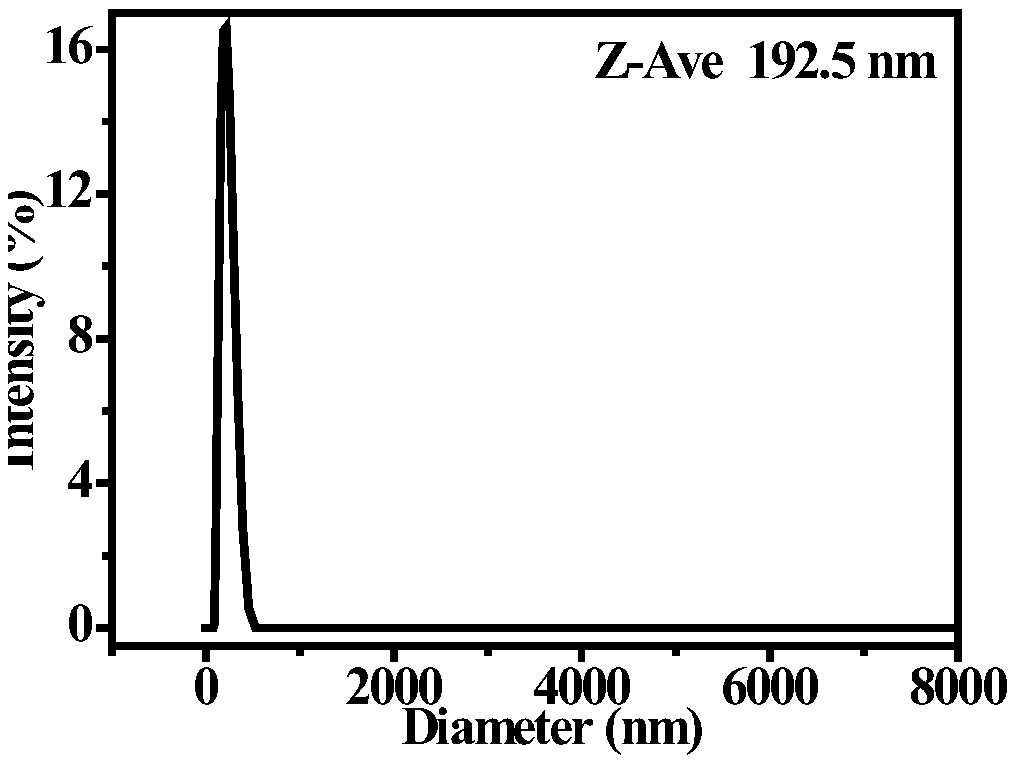

[0028] Weigh 0.027g of initiator and 100mL of deionized water in a 250mL four-necked bottle with a balance, then add 4.5g of trifluoroethyl methacrylate monomer after washing and refining with 5% potassium hydroxide aqueous solution and pass into a stable of nitrogen. Stir mechanically at 25°C at a speed of 190rmp for 20min, then heat up to 70°C to initiate polymerization. After the reaction is finished, cool to room temperature, and then filter with a 200-mesh gauze to remove a small amount of gel to obtain a monodisperse colloidal emulsion of polytrifluoroethyl methacrylate. according to figure 1 The particle size distribution diagram shows that the polytrifluoroethyl methacrylate colloid particle size is about 192nm, and the monodispersity index of the emulsion is only 3.9%, indicating that there is excellent monodispersity performance, and the polytrifluoroethyl methacrylate The static contact angle of the colloidal film is 125°, indicating that it has strong hydrophobic...

Embodiment 2

[0030] Weigh the deionized water of 0.055g initiator 100mL in the 250mL four-necked bottle with a balance, then add 5.5g of trifluoroethyl methacrylate monomer after washing and refining with 5% aqueous sodium hydroxide solution and pass into a stable Nitrogen, at 25°C mechanically stirred at 210rmp for 30min, then heated to 80°C to initiate polymerization. After the reaction is finished, cool to room temperature, and then filter with a 200-mesh gauze to remove a small amount of gel to obtain a monodisperse colloidal emulsion of polytrifluoroethyl methacrylate. figure 2 It is the SEM image of polytrifluoroethyl methacrylate, the particle size is about 214nm, and the monodispersity index of the emulsion is 4.2%. The structure of polytrifluoroethyl methacrylate colloidal microspheres arranged closely shows that it has excellent Monodisperse performance, the measured static contact angle of the colloidal film of polytrifluoroethyl methacrylate is 126°, indicating that it has str...

Embodiment 3

[0032] Weigh 0.05g of initiator and 100mL of deionized water in a 250mL four-necked bottle with a balance, then add 8.0g of trifluoroethyl methacrylate monomer after washing and refining with 10% aqueous sodium hydroxide solution and feed into a stable Nitrogen, mechanically stirred at 25°C at a speed of 230rmp for 50min, and then heated to 90°C to initiate polymerization. After the reaction is finished, cool to room temperature, and then filter with a 200-mesh gauze to remove a small amount of gel to obtain a monodisperse colloidal emulsion of polytrifluoroethyl methacrylate. image 3 It is the SEM image of polytrifluoroethyl methacrylate, the particle size is about 252nm, and the monodispersity index of the emulsion is 3.8%. The closely packed structure of polytrifluoroethyl methacrylate colloidal particles shows that it has excellent monodispersity Dispersion performance, the measured static contact angle of the colloidal film of polytrifluoroethyl methacrylate is 126°, ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com