High-strength emulsified asphalt cold recycled mixture

A technology for cold recycling mixture and emulsified asphalt, which is applied in the field of high-strength emulsified asphalt cold recycling mixture, can solve the problems of low cold recycling strength of emulsified asphalt, and achieves the effect of being beneficial to popularization and application, enhancing final strength and obtaining low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

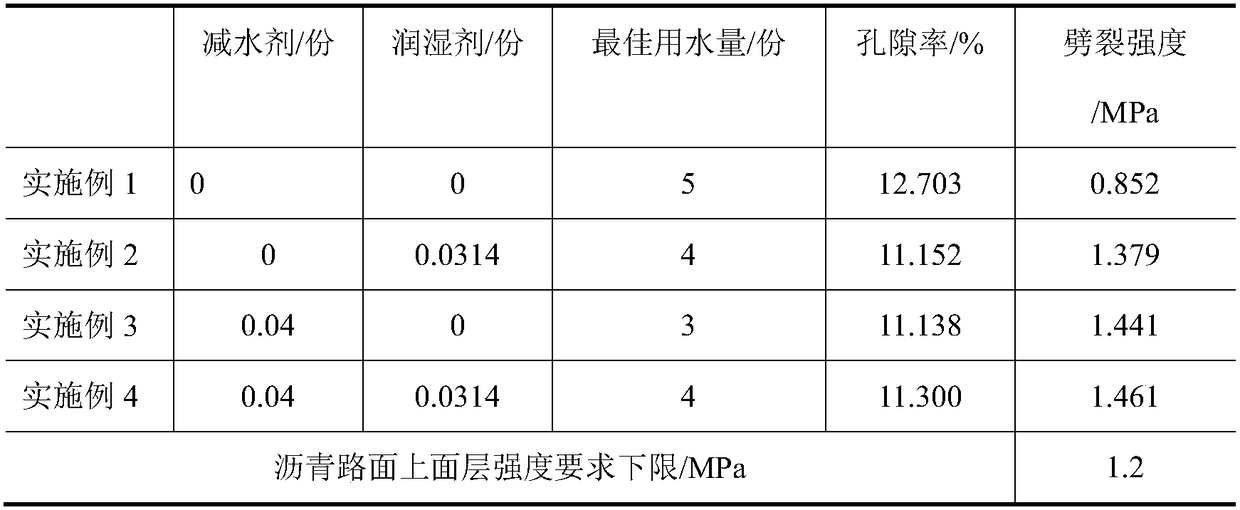

[0023] Weigh 19.7 parts of new aggregate, 74.3 parts of old aggregate, 4 parts of mineral powder, 2 parts of cement, and 3.75 parts of emulsified asphalt, with the amount of water added as a variable factor (2.0 parts, 3.0 parts, 4.0 parts, 5.0 parts, 6.0 parts), make test pieces respectively, test the Marshall test piece, and it calculates that the optimum external water content is 5 parts.

[0024] Weighing 19.7 parts of new aggregate, 74.3 parts of old aggregate, 4 parts of mineral powder, 2 parts of cement, and 6.295 parts of total water consumption, the addition of emulsified asphalt as a variable factor (2.5 parts, 3.5 parts , 4.0 parts, 4.5 parts, 5.0 parts), Marshall test pieces were made respectively, and the measured porosity and splitting strength are shown in Table 1. It calculates that the optimum amount of emulsified asphalt is 3.75 parts.

Embodiment 2

[0026] Weigh 19.7 parts of new aggregate, 74.3 parts of old aggregate, 4 parts of mineral powder, 2 parts of cement, 3.75 parts of emulsified asphalt, wetting agent (add 1 / 4 to water, add 3 / 4 to emulsified asphalt), among them, wetting The mass of wet agent is 0.5% of the total water. With the amount of water added as a variable factor (2.0 parts, 3.0 parts, 4.0 parts, 5.0 parts), standard Marshall test pieces were made respectively, and the porosity and splitting strength were measured respectively, as shown in Table 1.

Embodiment 3

[0028] Weigh 19.7 parts of new aggregate, 74.3 parts of old aggregate, 4 parts of mineral powder, 2 parts of cement, 3.75 parts of emulsified asphalt, and a water reducing agent, wherein the weight of the water reducing agent is 2% of the weight of the cement. With the amount of water added as a variable factor (2.0 parts, 3.0 parts, 4.0 parts, 5.0 parts), standard Marshall test pieces were made respectively, and the measured porosity and splitting strength are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com