Energy-storing flywheel rotor loop manufactured by winding steel wires

An energy storage flywheel and steel wire winding technology, which is applied in the direction of flywheel, mechanical energy control, mechanical equipment, etc., can solve problems such as insufficient, deformation and coordination of hub strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

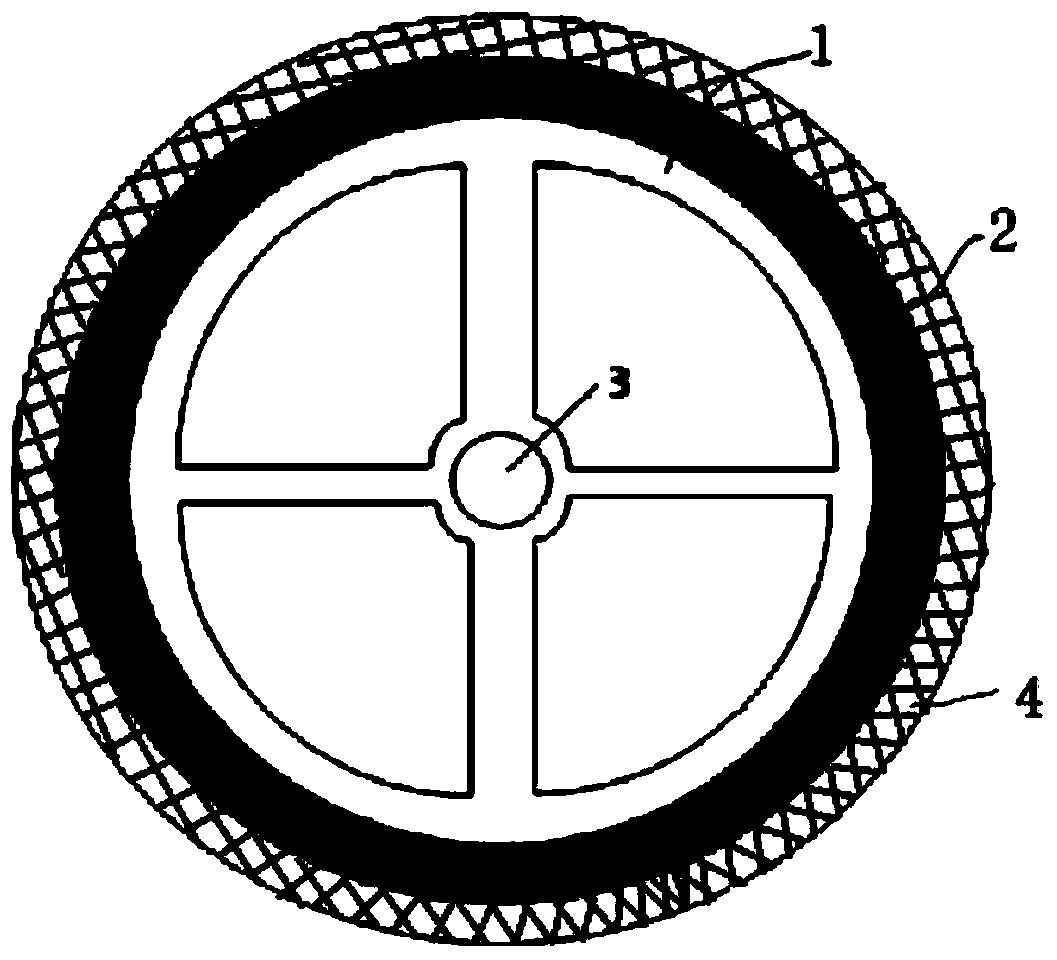

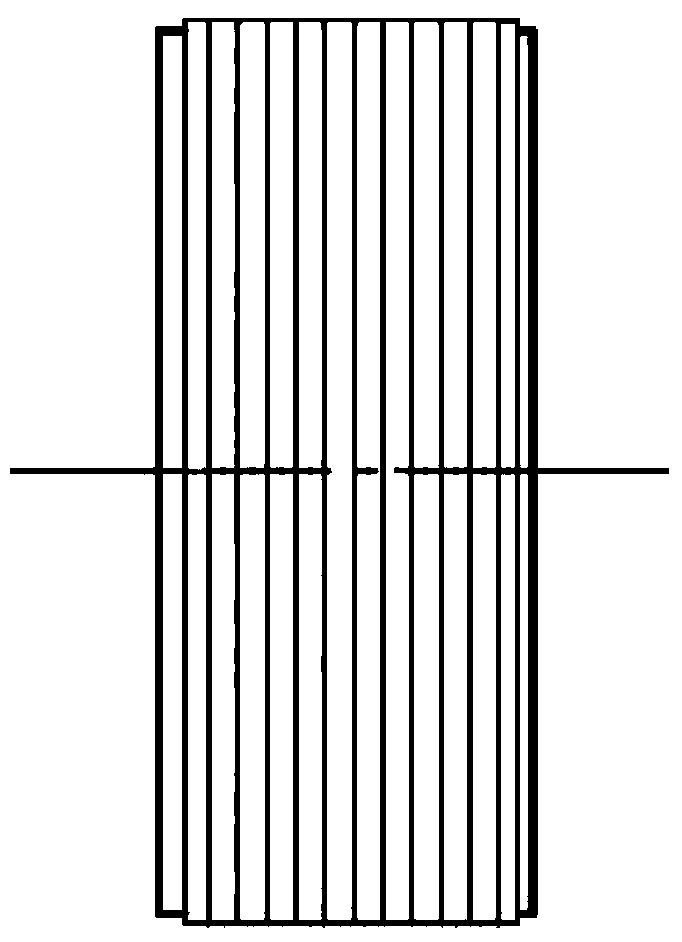

[0017] like figure 1 , 2 As shown, the flywheel rotor described in this example is disc-shaped composed of a metal matrix hub 1, a steel wire prestressed winding layer 2 and a composite material ring 4, and the center of which is a bearing hole 3 for connecting with the flywheel. When in use, it is only necessary to install the rotor manufactured according to the above structure on the bearing of the flywheel through the bearing hole 3 .

[0018] The metal base hub 1 can be made of ultra-high-strength steel, titanium alloy or high-strength aluminum alloy in the prior art, and the high-strength steel wire is wound on the metal hub base under normal stress by a winding machine. In the winding process, in order to avoid the compression deformation of the metal hub base due to the winding tension of the outer steel wire, which will cause the tension reduction of the inner steel wire and the relaxation of the steel wire winding layer, a variable tension winding process with monoto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com