Full industrial solid waste high strength ready-to-use foamed concrete material and preparation method thereof

A technology for industrial solid waste and concrete, which is applied in applications, ceramic products, household appliances, etc., can solve the problems of low volume of solid waste and large consumption of natural minerals, achieve a wide range of applications, alleviate the depletion of production resources, and reduce the production cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

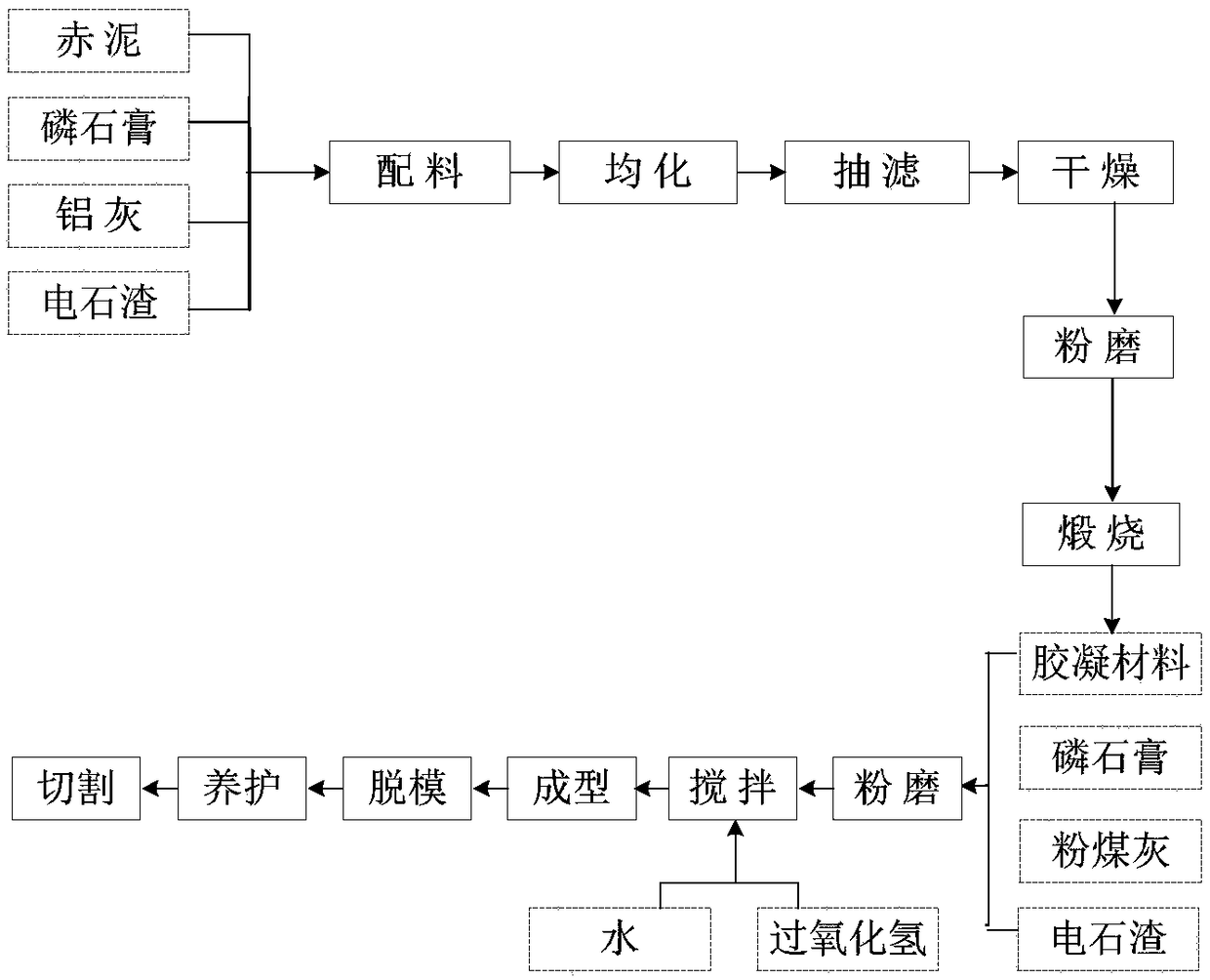

[0055] Such as figure 1 Shown, a kind of method that whole industry solid waste prepares cementitious material, comprises the steps:

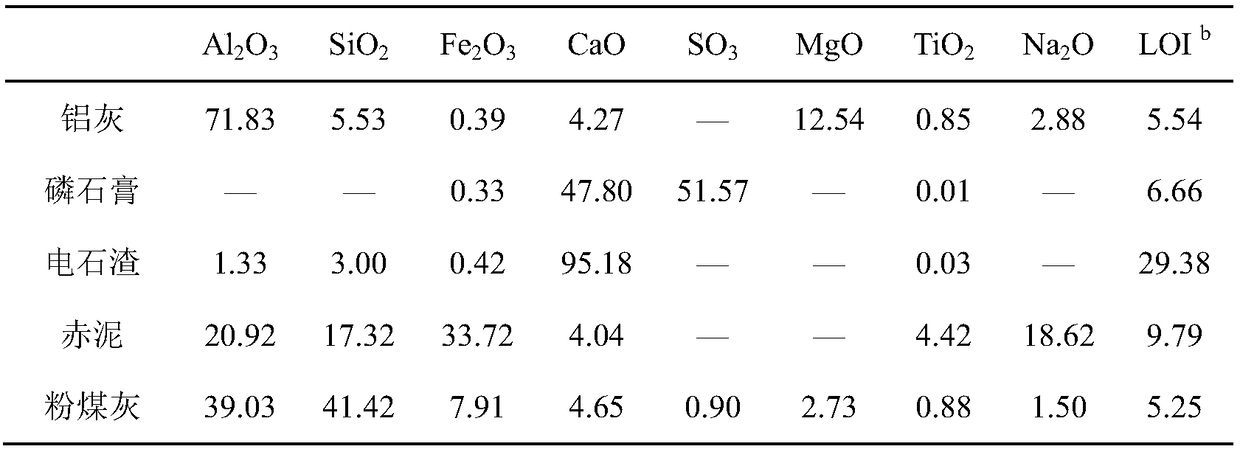

[0056] (1) The total amount of raw materials is 1kg, and the mass ratio is 15%: 24%: 44%: 17%. Weigh aluminum ash, red mud, carbide slag and phosphogypsum respectively, and add different raw materials into wet milling In the middle grinding, the mixture is ground to a fineness of 45 μm and 30% of the sieve. Among them, the chemical compositions of aluminum ash, red mud, carbide slag, phosphogypsum and fly ash are shown in Table 1;

[0057] (2) Put the raw material after grinding in step (1) into the homogenization tank, add water according to the mass ratio of 1:4 (raw material and water) to obtain a slurry, heat the slurry to 50°C, wash and stir with water for 3 hours, Dissolve the soluble substances in aluminum ash and carbide slag into the homogenization tank;

[0058] (3) Hydraulically filter the slurry to a water content of 18% (wt.%), ...

Embodiment 2

[0067] A method for preparing a high-strength ready-to-use foamed concrete material from industrial solid waste, comprising the following steps:

[0068] (1) Take by weighing 374.22g, 71.28g, 49.5g and 5g of the cementitious material in Example 1 and phosphogypsum, fly ash and carbide slag respectively, mix uniformly to obtain a mixture, and grind the mixture to fine 30% sieve with a degree of 45μm;

[0069] (2) Put the pulverized mixture in step (1) into the reaction tank, add warm water at 35°C at a water-cement ratio of 50%, stir for 2 minutes, and then add 30% peroxide Hydrogen solution, the amount of hydrogen peroxide added is 4.3% of the volume of warm water. After stirring for 30s, pour the slurry into the mold box for molding; 28 days under the above curing conditions. According to the national standard GB / T 11969-2008 "Autoclaved Aerated Concrete Performance Test Method", the concrete test block prepared in this example was tested, and the performance was compared w...

Embodiment 3

[0073] 1. A method for preparing cementitious materials from all industrial solid wastes, comprising the steps of:

[0074] (1) The total amount of raw materials is 1kg, according to the mass ratio of 14%: 26%: 43%: 17%, weigh aluminum ash, red mud, carbide slag and phosphogypsum respectively, and add different raw materials into the powder in the wet mill Grinding, grinding the mixture to a fineness of 45 μm and 30% of the sieve. Among them, the chemical composition of aluminum ash, red mud, carbide slag, phosphogypsum and fly ash are shown in Table 1;

[0075] (2) Put the ground raw material in step (1) into the homogenization tank, add water according to the mass ratio of 1:3 (raw material and water) to obtain a slurry, heat the slurry to 60°C, wash and stir for 4 hours, and make The soluble substances in aluminum ash and carbide slag are dissolved into the homogenization tank;

[0076] (3) Press filter the slurry to a water content of 25% (wt.%), send it to a 600° C. dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com