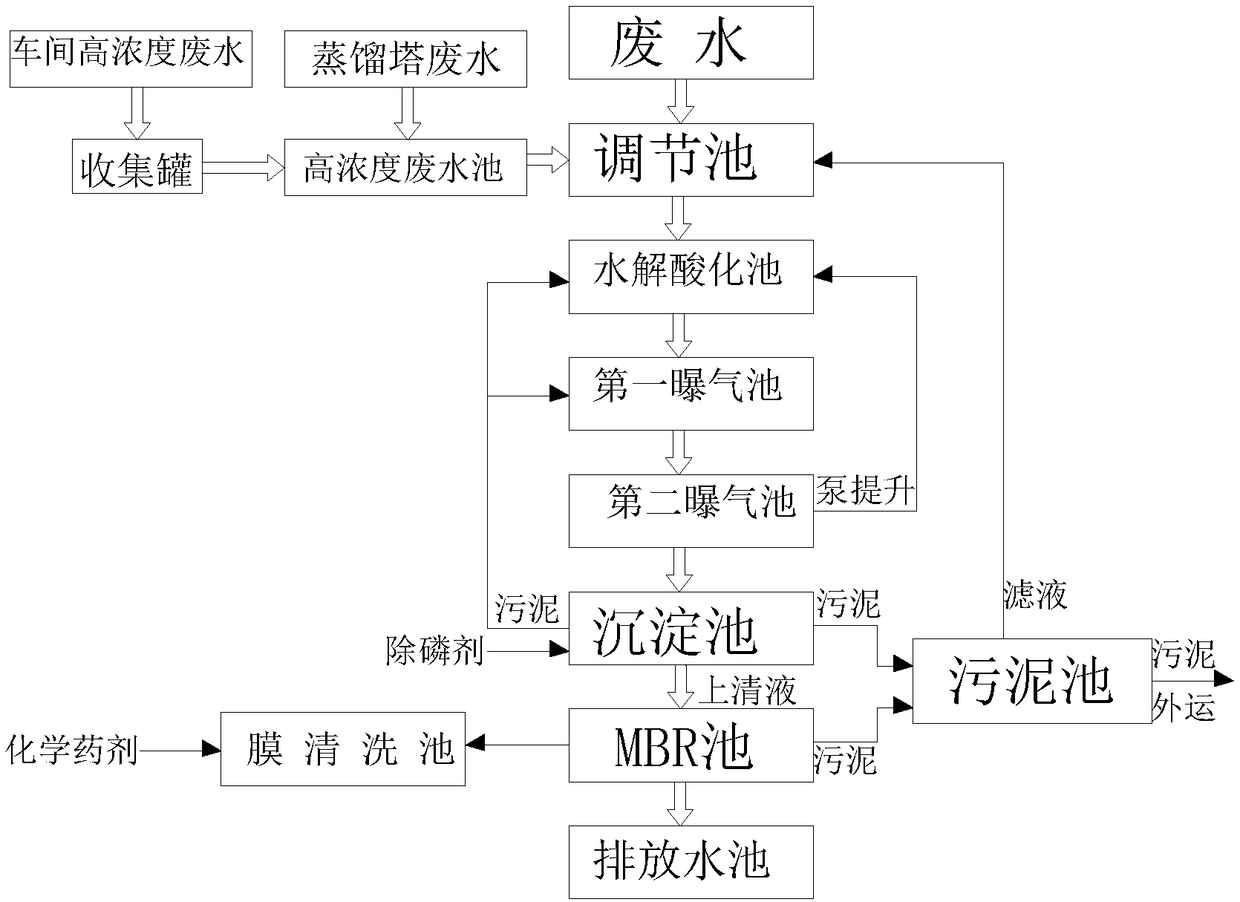

A biopharmaceutical wastewater treatment system and method

A technology for sewage treatment system and biopharmaceuticals, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , the problem of high temperature, to achieve the effect of reducing treatment costs and improving sludge utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Alcohol distillation waste water is collected and stored in a high-concentration waste water pool, and the water temperature is lowered by stirring with a mixer. The high-concentration wastewater pool is equipped with a lift pump controlled by the liquid level, which starts at a high liquid level and stops at a low liquid level. And set the ultra-high, ultra-low liquid level alarm device. The high-concentration wastewater pool adopts a steel structure, which is above ground and adopts a carbon steel anti-corrosion or stainless steel structure. The wastewater in the high-concentration wastewater pool is slowly transferred to the regulating tank through the lift pump.

[0050] The culture medium in the workshop and residual alcohol from equipment wiping are collected in the collection tank of the workshop, transported to the wastewater station by forklift, stored in the high-concentration wastewater pool, and evenly transferred to the regulating pool on a regular basis. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com