Efficient welding equipment for serological pipettes

A technology for welding equipment and pipettes is applied in the field of high-efficiency welding equipment for serological pipettes, and can solve the problems of affecting the air-tightness of pipettes, high labor intensity, and lack of smooth coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

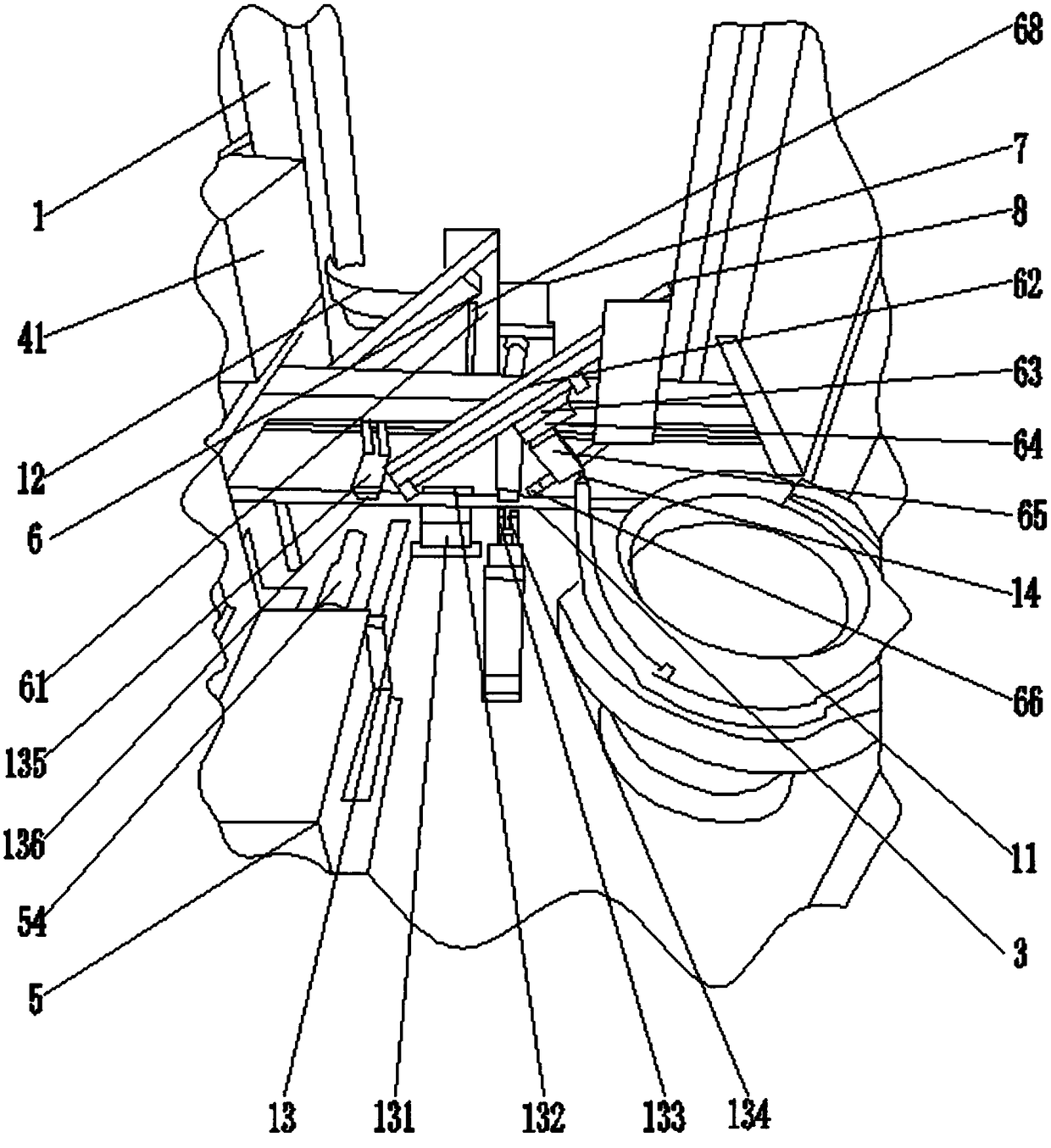

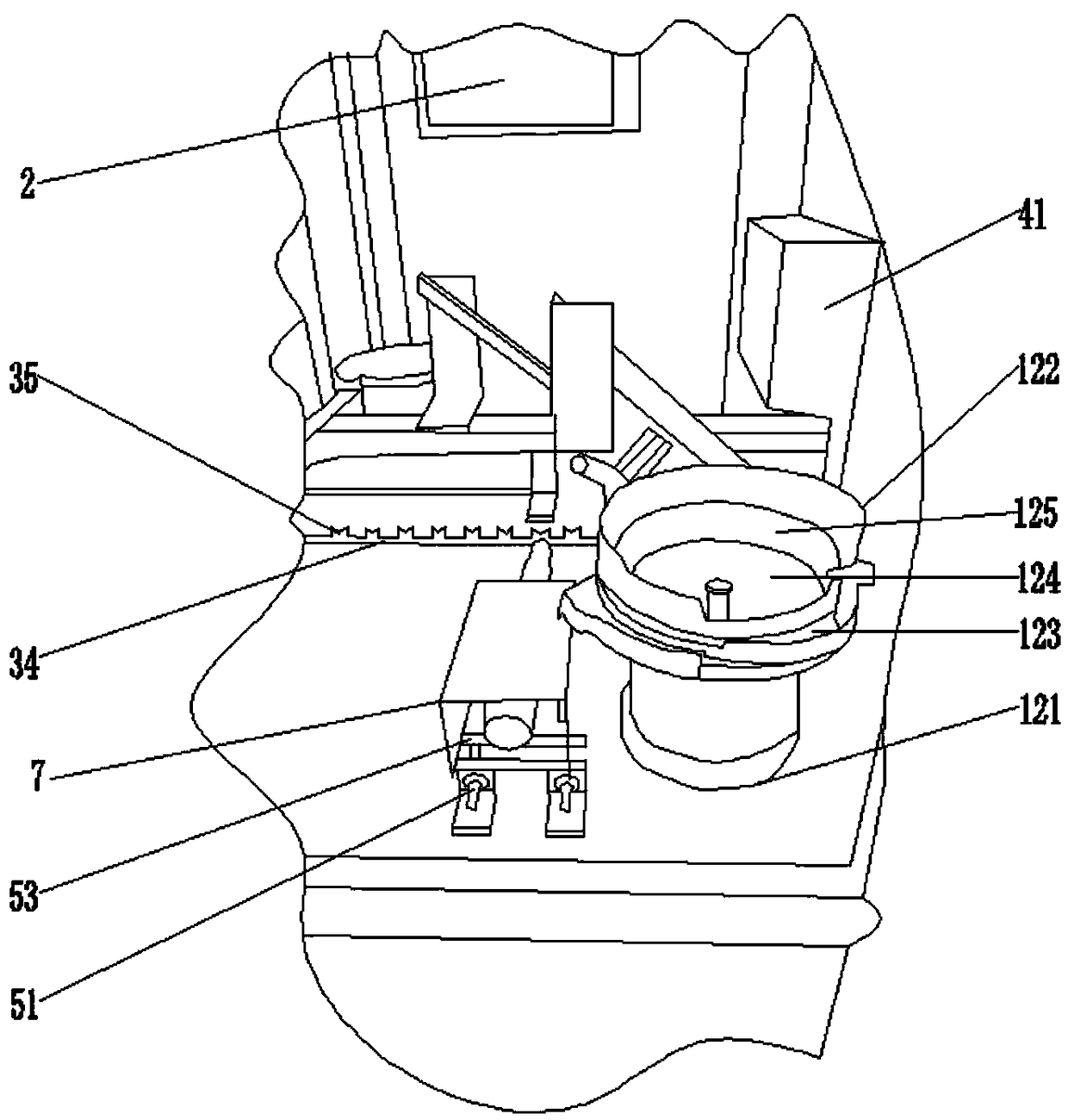

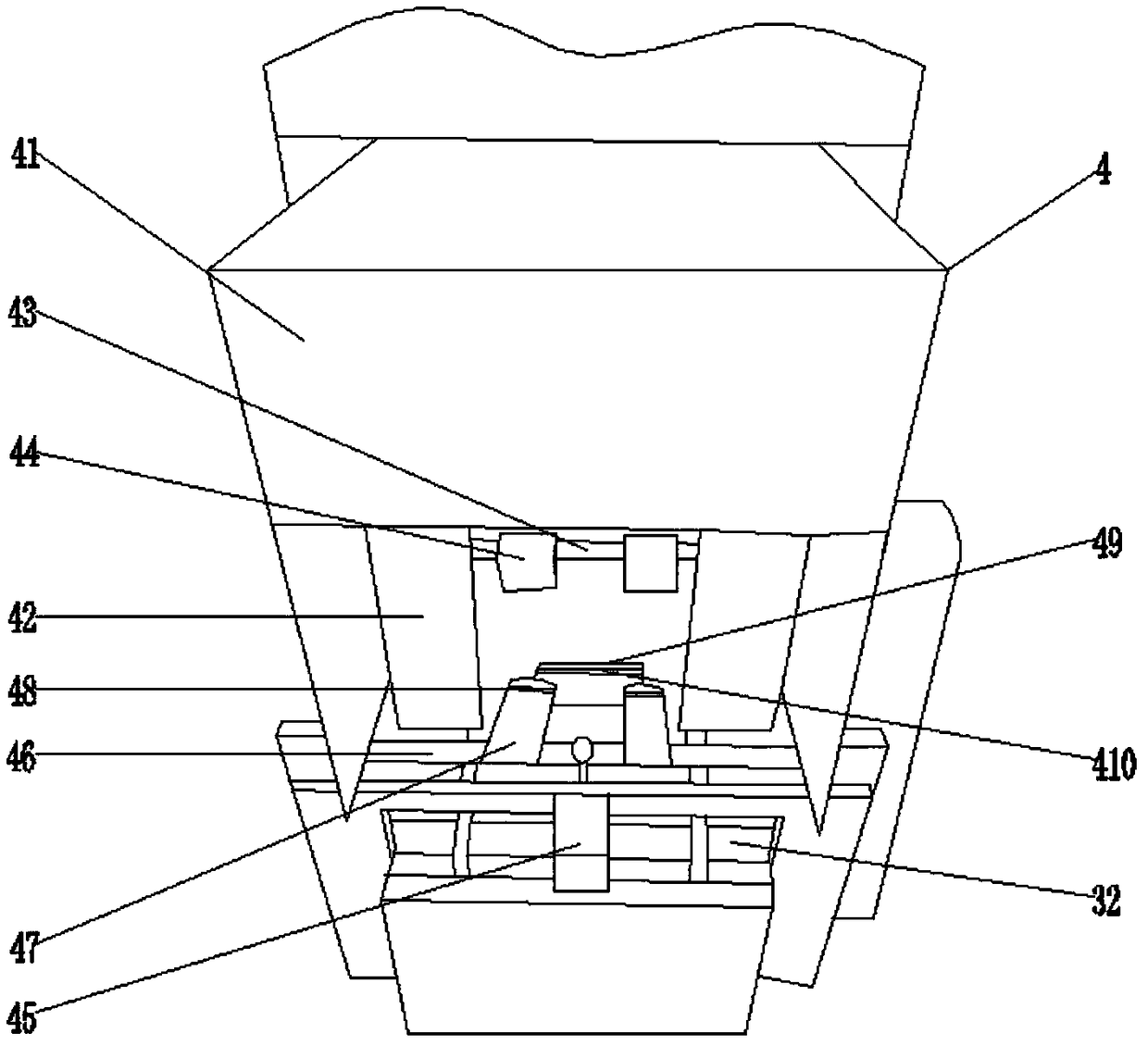

[0043] Such as figure 1 and figure 2 The high-efficiency welding equipment for serological pipettes shown includes a frame 1, a controller 2 arranged on the frame, and a conveying mechanism 3 arranged on the frame. The first ultrasonic welding assembly 5 on one side of the mechanism, such as the one above the other side of the conveying mechanism Figure 4 The second grasping mechanism 6 shown, the second ultrasonic welding assembly 7 located on the other side of the conveying mechanism, the first grasping mechanism 8 located above one side of the conveying mechanism, and the one below the output end of the conveying mechanism cooperate with the conveying mechanism as Figure 6 Shown drive mechanism 9 and be positioned at delivery mechanism output end such as Figure 8 As shown in the collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com