Preparation method of titanium dioxide photocatalysis composite material

A technology of photocatalytic materials and composite materials, which is applied in the field of preparation of titanium dioxide photocatalytic composite materials, can solve problems such as separation, difficulty in particles, and easy agglomeration, and achieve the effects of easy separation and recovery, improved efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

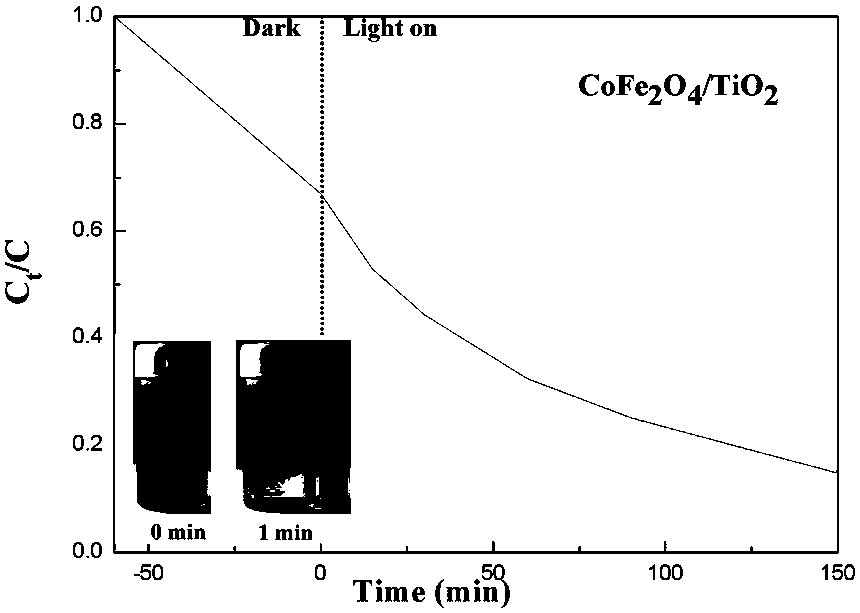

Image

Examples

specific Embodiment approach 1

[0011] Specific implementation method 1: 1. After drying, 300-mesh activated carbon is refluxed in sulfuric acid at 90°C for 2 hours, and after repeated washing, it is moved into a vacuum drying oven for drying treatment at 200°C for 12 to discharge adsorbed gas and other impurities; 2. Use solvothermal To synthesize ferrimagnetic ferrite / activated carbon, weigh two kinds of soluble metal salts (the atomic ratio of divalent metal ion (Co) to ferric salt is 1:2) in diethylene glycol solution according to a certain ratio, After stirring in an 80°C oil bath for 2 hours, add diethanolamine (1:6 volume ratio to diethylene glycol) dropwise, and then gradually add NaOH (10:1 molar ratio to ferrite) diethylene glycol solution and activated carbon (The molar ratio of ferrite to activated carbon is 1:100) diethylene glycol solution, uniformly mix the above liquid, solvent heat treatment at 200 for 8 hours, wash and dry after magnetic separation; 3. Titanic acid with a mass ratio of 1:1 ...

specific Embodiment approach 2

[0012] Specific implementation method two: 1. After drying, 400 mesh activated carbon is refluxed in sulfuric acid at 70°C for 2 hours, and after repeated washing, it is moved into a vacuum drying oven at 150°C for drying treatment for 24 hours, and the adsorbed gas and other impurities are discharged; 2. Using a solvent Thermally synthesize ferrimagnetic ferrite / activated carbon, weigh two kinds of soluble metal salts according to a certain ratio (the atomic ratio of divalent metal ion (Ni) to ferric salt is 1:2) and add them to the diethylene glycol solution , after stirring in an oil bath at 100°C for 0.5h, dropwise add diethanolamine (1:10 volume ratio to diethylene glycol), and then gradually add NaOH (15:1 molar ratio to ferrite) diethylene glycol solution and activated carbon (the molar ratio of ferrite to activated carbon is 1:100) diethylene glycol solution, mix the above liquid evenly and heat-treat the above liquid at 250°C for 6 hours, wash and dry after magnetic se...

specific Embodiment approach 3

[0013] Specific implementation method three: 1. After drying, 300 mesh activated carbon is refluxed in 80°C sulfuric acid for 3 hours, and after repeated washing, it is moved into a vacuum drying oven for 180°C drying treatment for 18 hours, and the adsorbed gas and other impurities are discharged; 2. The solvent is used Thermally synthesize ferrimagnetic ferrite / activated carbon, weigh two soluble metal salts according to a certain ratio (the atomic ratio of divalent metal ion (Fe) to ferric salt is 1:2) and add them to the diethylene glycol solution After stirring in an oil bath at 90°C for 1 hour, add diethanolamine dropwise (1:8 volume ratio to diethylene glycol), and then gradually add NaOH (12:1 molar ratio to ferrite) in diethylene glycol solution Diethylene glycol solution with activated carbon (the molar ratio of ferrite to activated carbon is 1:100), uniformly mix the above liquid, solvent heat treatment at 220°C for 7 hours, wash and dry after magnetic separation; 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com