High-speed powder stirrer

A mixer and powder technology, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of dust, time-consuming and laborious, and iron oxide pigment powder sticking to the inner wall of the cylinder, etc. The effect of mixing evenly, maintaining consistency, and reducing the number of times to clean the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

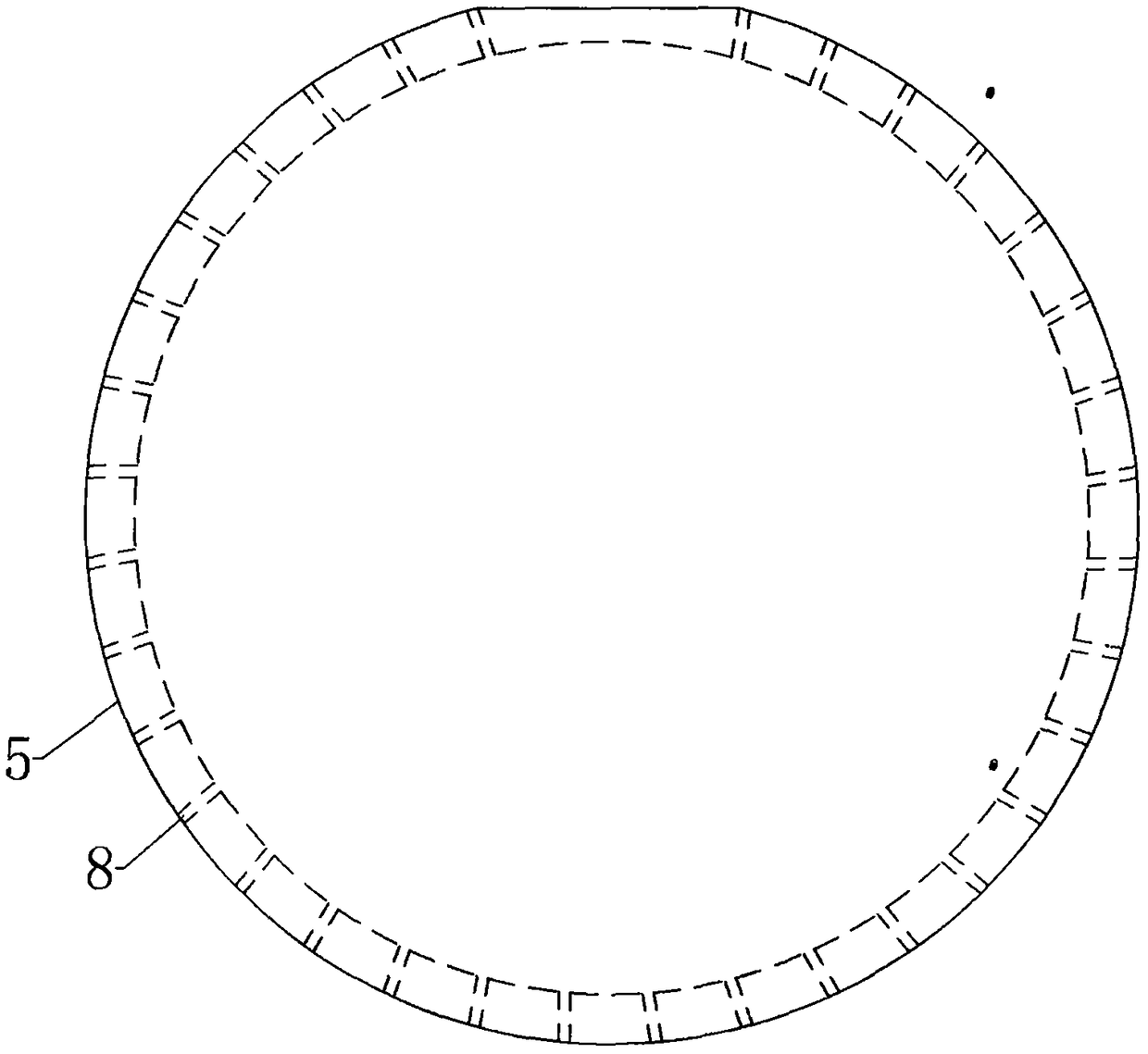

[0016] Such as figure 1 with figure 2 As shown, the high-speed powder mixer includes a cylinder 1, a cover 2 is provided on the top of the cylinder 1, and an agitator 3 is provided at the middle of the inner bottom of the cylinder 1. The agitator 3 includes a motor 31 connected to the output shaft of the motor 31. The stirring plate 32, the cover 2 is provided with a high-pressure gas pulse injector, and the high-pressure gas pulse injector includes a connecting pipe 4 pierced in the middle of the cover 2, a nozzle 5 arranged at the bottom of the connecting pipe 4 and extending into the cylinder 1 , the electromagnetic pulse valve 6 that is arranged on the connecting pipe 4 top, the conveying pipe 7 that is connected with the electromagnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com